Last Updated on October 30, 2024 by Owen McGab Enaohwo

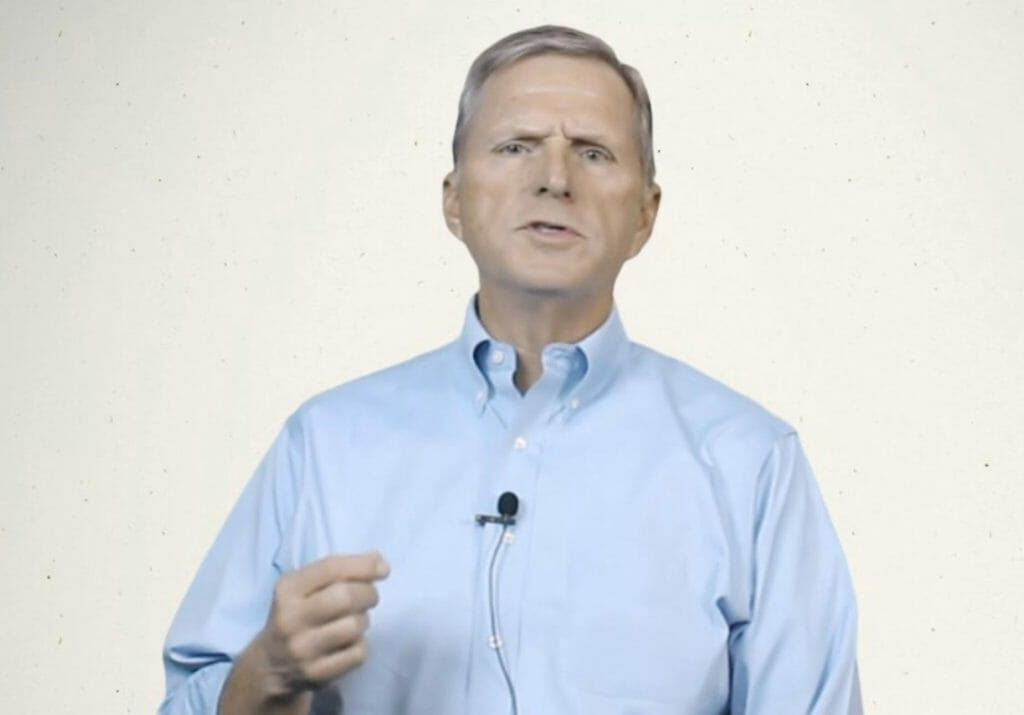

Processes are an important part of running a business. They help to simplify tasks, understand insights, and keep work organized. In this episode of the Process Breakdown Podcast, we interview Joe Bockerstette, a partner at Business Enterprise Mapping, an organization aimed at transforming organizations by changing how they solve problems and manage work.

Joe speaks on how to measure and improve your company’s process and how it would positively affect your company afterward. He shares the common mistakes companies make with processes, how to resolve them, and why business mapping and measuring your process is important.

Listen to this audio interview:

Listen to more expert interviews like this:

Key Resource List:

Show Notes:

0:05 – Podcast intro

0:47 – Dr. Weisz shares the best solution for documenting standard operating procedures, Sweet Process, highlighting a 14-day free trial.

1:33 – The guest speaker, Joe Bockerstette, is introduced.

2:30 – The guest talks about the time he won Golfweek 2019 Father of the Year, and his experience as a board chair of the National Down Syndrome Society and co-founder of the Down Syndrome Association of Northeast Indiana.

6:29 – Mr. Bockerstette shares what process-based measurements mean.

7:49 – Mr. Bockerstette talks about the process-related pain points he faces when he’s working with companies.

9:08 – The guest speaker shares his process, including how he starts measuring and improving a company’s process.

11:46 – The speaker shares the biggest mistakes companies are making with process measuring.

13:57 – Mr. Bockerstette speaks on one of the main characteristics of process measurement.

16:21 – The speaker shares how he handles doubts and pushbacks from clients when working to improve their process.

18:03 – Mr. Bockerstette gives an example of a client they worked with and the pushbacks they encountered and how he went about the situation.

20:06 – Mr. Bockerstette talks about business enterprise mapping and how his company handles it.

22:44 – Mr. Bockerstette talks on the types of process measurements.

26:05 – The guest speaker shares the questions people who feel business mapping isn’t important should ask themselves.

27:56 – Outro

Guest Profile:

Joe Bockerstette is an executive and consulting partner with more than thirty years of experience under his belt, including as a CEO, supply chain, and process improvement professional.

He is currently in partnership with Business Mapping Enterprise, an enterprise that helps organizations by changing how they solve their problems and manage work. Using the Perigon Method, they help their clients improve and deploy business processes.

Transcript of this Interview:

Speaker 1: Welcome to the Process Breakdown Podcast, where we talk about streamlining and scaling operations of your company, getting rid of bottlenecks and giving your employees all the information they need to be successful at their jobs. Now let’s get started with the show.

Dr. Jeremy Weisz: Dr. Jeremy Weisz here, host of the Process Breakdown Podcast, where we talk about streamlining and scaling operations of your company, getting rid of bottlenecks and giving your staff everything they need to be successful at their job. There’s really no better person to talk about this today. I’m going to introduce today’s guest, Joe Bockerstette, in a second.

Dr. Jeremy Weisz: Before I do, this episode is brought to you by SweetProcess. And if you have had team members ask you the same questions over and over, and it’s the 10th time you’ve spent explaining it, there may be a better way. Joe, right? I mean, probably. So SweetProcess is a software that makes it drop dead easy to train and onboard new staff and save time with existing staff. And I was talking to Owen and he was saying they use it for universities, banks, hospitals, software companies, but I didn’t realize they use it for first responder government agencies and they use it in life and death situations to run their operation.

Dr. Jeremy Weisz: So if you want to get and help document the repetitive tasks, you can use SweetProcess. They have a 14-day free trial, no credit card required. Go to sweetprocess.com, that’s sweet like candy, S-W-E-E-T process.com. I’m super excited. Today, we have Joe Bockerstette, who’s a seasoned executive and consulting partner. You can’t get people… You know, Joe has easily 30 years of experience as a CEO, process improvement professional, private equity, angel investor. Such a diverse body of work that you have. And he began his career in PricewaterhouseCoopers, he’s led two CPG companies, if that wasn’t enough, co-founder in a private equity firm, co-founder in an angel fund called Main Street Venture Fund, and now runs Business Enterprise Mapping. You can check it out, businessmapping.com.

Dr. Jeremy Weisz: And you know, Joe, for me, the most impressive part about your career, your accomplishments, you may already know what I’m going to say, but is being honored as Golf Week 2019 father of the year, served as a board chair of the National Down Syndrome Society and co-founder of the Down Syndrome Association of Northeast Indiana. So thanks for joining me, Joe.

Joe Bockerstette: Well, thank you for having me. Looking forward to the conversation today.

Dr. Jeremy Weisz: I want to abandon the whole conversation about process. No, I’m sort of kidding, but I really want to hear about what that was. I was choked up by the video I watched today of Golf Week, 2019 father of the year. So maybe just paint the picture for a second, that day, and then we can get into process, but I feel like this is more important right now.

Joe Bockerstette: Well, thanks. I’ll be brief because this could take the whole time. But my daughter Amy has Down syndrome. She’s 21 years old. She’s been playing golf since she was 14 and it turns out she’s a good golfer. And so she was the first person with Down syndrome to play in Arizona High School State Girls Tournament, which she did as a junior and a senior. And she was offered a scholarship to the local community college, Paradise Valley Community College, where she’s playing golf on a full scholarship today.

Joe Bockerstette: PGA tour came through the Waste Management Phoenix Open in 2019 and contacted local Special Olympics and asked if they could provide a golfer who could possibly walk the hole with Gary Woodland. Gary had won the tournament the prior year. And so they contacted us and so Amy was told that she was going to be able to walk the very famous 16th hole at the Waste Management Phoenix Open. Thousands and thousands of people in the stands, very rowdy. I knew that they were going to allow her to play the hole, she did not. And so we went to the stadium that day, they let us inside, we waited for Gary. Amy was very, very excited at the crowds. Gary Woodland showed up and what you saw then on the video is what took place.

Joe Bockerstette: He offered her the opportunity to play the hole, didn’t expect much, had seen her resume, knew that she could play but didn’t expect much from her performance that day, and of course she surprised the crowd.

Dr. Jeremy Weisz: She killed it.

Joe Bockerstette: And ultimately the golfing community with that and PGA Tour had miked her and taped the entire event. We thought it was a great moment that day. The next day, when the video came out, it just sort of took over our lives for the next year and a half. So we’re very proud of Amy. She continues to play college golf today and she’s been all over the country speaking, attending charity events and meeting just a fabulous amount of great people. Yeah.

Dr. Jeremy Weisz: I mean, it’s a lesson. I encourage anyone to watch it. And it’s a lesson in mindset. And some of the self-talk that she says before she hits, did you go over that with her or how did she come to that?

Joe Bockerstette: That’s entirely Amy. We say, “You got this,” a lot. And actually we didn’t realize all that was going on of course until the next day. So Amy has sort of three things that she tells herself consistently, “I got this,” “You can do this,” and “Breathe and believe.” And she’s not encumbered with self-doubt in that way. When you put her in front of a large cheering crowd, she’s far more likely to perform.

Dr. Jeremy Weisz: She loves it. She loves it. She’s like, “They love me.”

Joe Bockerstette: She does. People ask her, “Did you get nervous?” And she doesn’t get nervous, she gets very excited. She loves to perform for people. And of course that’s the biggest, most exciting stage you can play if you’re a golfer.

Dr. Jeremy Weisz: Amazing. No, thank you for sharing that. I think I’m going to watch that video [crosstalk 00:06:20]

Joe Bockerstette: You bet. That’s the more fun part of this call, I can promise you.

Dr. Jeremy Weisz: Every single person should watch that video.

Dr. Jeremy Weisz: So process-based measurement. And this is like a non-sexy topic though, that actually moves the needle on businesses. So what does that mean? Process-based measurement?

Joe Bockerstette: Well, the first principle to think of is an organization is comprised of people, process, technology. And a process is really a name for organization workflow. And in our firm, we take the philosophy that organization workflow is the foundation from which all other pieces of your business model should be built. When you are improving your enterprise, you’re improving workflow in that enterprise. And most organizations do not attack it in that way. Most organizations attack it organizational structure wise. They tend to think in terms of people, not process and workflow. And the way they organize the structure tends to be a barrier to actually performing the work better.

Joe Bockerstette: And process measurement in particular is an area where most organizations come way short in measuring what ought to be measured to drive the kind of improvement that they want to drive.

Dr. Jeremy Weisz: So Joe, you enter into a company, company calls you and what are the pain points they’re experiencing?

Joe Bockerstette: Yeah. So you hear a lot about organization silos. You hear a lot about not having control of the business, especially in high growth areas. You hear a lot about complexity. “We’re having difficulty getting work out on time or having difficulty with quality being produced. We’ve added many reviews and approvals to try to solve this problem and it only seems to make it worse.”

Joe Bockerstette: And so the pain points tend to be in not performing, not delivering what the customer desires, and being very, very inefficient internally. We get a number of calls where we’ve benchmarked and our costs in this area are way higher than our competition. We don’t know why. And so there’s a variety of reasons. Fundamentally though it is work flowing across the organization, which becomes unsolvable to those in the organization. Like you’ve got the politics, you’ve got the silos, you’ve got the fiefdoms, and folks don’t know how to begin to get at work as it’s flowing across departments, directors, VPs, whatever it might be.

Dr. Jeremy Weisz: Yeah. So I’d love to hear your process. You walk in day one, what do you do?

Joe Bockerstette: Right. So we begin with what we call a business system architecture. So the beginning of our process is to evaluate the workflow that is your pain point in the context of a business system and business process architecture. So it begins by.. Well, let’s take an accounting department just to pick a very obvious one, lots of folks do. What are the processes in your accounting department that ultimately deliver the purpose of your business system? The purpose of the business system in accounting, primarily, is to deliver accurate, timely and complete month-end financials, right? That’s the primary deliverable of account. And you also deliver checks to vendors. You also deliver payroll checks to employees. You also deposit cash from customers. And so by understanding the primary mission of a department or a business system as we would call it, accounting being a business system, then what processes exist inside that business system that align together to deliver those large system deliverables that really drive the purpose of the unit.

Dr. Jeremy Weisz: And so once you step in, you look at their current processes?

Joe Bockerstette: Right. Yeah. So we identify the processes that exist. For instance, in an accounting department, you’re going to have a process called accounts receivable, accounts payable, month-end close, possibly a general ledger, journal entries, payroll. Those are the variety of kind of processes that you would find in an accounting department. Once we’ve identified those processes, we identify who’s responsible for each of them, what we would call a process owner. And then we team with process owners to create what we call process playbooks that define how the work is done today, what the problems are with that work, what we call red clouds, the problems and opportunities preventing you from doing it better and then producing a plan to go solve those problems and deliver that work more effectively and efficiently. And we do it as a batch of processes. So if the accounting department has 10 processes, we would study those 10 in a single project, looking for the disconnects, the gaps, the handoffs, the problems that exist between those processes that drive bigger opportunity for improvement.

Dr. Jeremy Weisz: What are the biggest mistakes you see people making?

Joe Bockerstette: Well, the biggest mistakes are narrow focus. And so it’s a lack of understanding how my work here impacts those downstream. The largest red cloud that we typically find is a disconnect between a supplier to the process and the needs of that process. In order for me to be successful, I need for my primary supplier to be successful as well. And so the larger the reach, the greater the value of the benefits. And just connecting the workflow is a eyeopening experience for senior leadership. We have a workshop we call System Alignment Workshop where we give process owners string, tape, and scissors, and they connect the dots between their processes and other processes. And senior leaders can come into this workshop and their heads explode at the complexity of what they’re seeing on the wall.

Dr. Jeremy Weisz: Are those actually physical…

Joe Bockerstette: Yeah. It’s paper. It’s posters on walls with string, tape, and scissors being strung together to connect the dots between process-process, and system to system. And it’s a paradigm shift for folks to think, “Wow, now I see why things don’t work here.” We had one client where the senior VP commissioned the work. It was a product development system. And after that very first System Alignment Workshop, he rolled up the posters, took them to his conference room, re-put them on his wall and still today he takes visitors into his conference room to show them the mess of spaghetti that he started with. And this client goes back probably six or seven years now.

Dr. Jeremy Weisz: It’s like a badge of honor, like unraveling the spaghetti.

Joe Bockerstette: It is. Here’s what we started with and here’s where we’re at today. And of course it’s a journey, not a destination when you’re talking about workflow improvement.

Dr. Jeremy Weisz: Yeah. And we were talking before we hit record, I wanted you to talk about… Maybe walk through a specific case study. And there was a large consumer products company, and you had mentioned synchronization. So I thought you’d talk about that.

Joe Bockerstette: So synchronization is one of the main characteristics of process measurement that virtually no one gets or implements. Synchronization gets to the extent to which the process is aligned with the customer’s needs; volume, variety, rate, pace, those sorts of issues. And this very large consumer products company we worked with, this goes back 15 years ago maybe, had hired us to see what we could do with their supply chain. This was a liquid soap, a liquid detergent, and we showed them how they could go from a very long cycle time of I think it was around 60 days to next day.

Dr. Jeremy Weisz: Wow.

Joe Bockerstette: You could take orders today, you could process them tomorrow, and you could ship them the next day. And it was such a paradigm shift and such a mind blowing concept for them, they came back to us and said, “No, we can’t do that. That’s too radical. Let’s go fix what we’re doing already. Let’s fix the process we’re using.” And our response was, “That won’t work. You can’t fix that process and expect to get the kind of results we’re describing. And by the way, shifting this process will be easier than trying to fix your other process.” And so they acquiesced, we implemented the change and inside two weeks it was working beautifully and they dramatically took costs out of their system, et cetera. And so the whole key to that change was looking at the scenario differently, measuring a different characteristic they had never considered before. And in doing that, the answer became obvious. And actually the implementation solution was equally obvious and pretty easy to do. It was…

Dr. Jeremy Weisz: What’s interesting about… Go ahead.

Joe Bockerstette: … shift in mindset, not a physical barrier. It was all how they thought about the problem.

Dr. Jeremy Weisz: Yeah. That’s what I was going to say, Joe. Interesting. It’s a paradigm shift, right?

Joe Bockerstette: It is.

Dr. Jeremy Weisz: Because if you go, “Hey, we can get it from 60 days to like 45 days,” there would be no pushback.

Joe Bockerstette: That’s right.

Dr. Jeremy Weisz: But if it’s with the same process, do you ever find yourself tempering what you’re saying as far as like, we may be able to get to next day or we’ll try for 45… knowing next day we could definitely accomplish that. Or how do you temper their pushback and paradigm?

Joe Bockerstette: That’s an excellent question. I would tell you, after the many years that I’ve done this, we’re pretty sure of what we’re doing. And we have a very good understanding of what the change looks like and what kind of performance improvement it delivers. I will also tell you that the success of our project is entirely dependent upon the client, not the consultants. We do the same thing that we’ve been doing for 30 something years. We know exactly what works. When we have great clients who are committed to great change, it’s a beautiful thing.

Dr. Jeremy Weisz: They execute.

Joe Bockerstette: And the results are mind blowing. Seriously mind blowing. And when they don’t believe it, when they don’t want to do it, when they don’t follow through, there’s not much we can do to overcome that weakness. And so we’re very early on assessing the quality of our clients and their ability to execute change, and frankly, some of our greatest success stories were clients who weren’t large, sophisticated, deep thinkers in this area but were just good problem-solvers who listen, did what we recommended and had phenomenal success.

Dr. Jeremy Weisz: Yeah. I would say they probably need coachability. They’re just like, “Okay, just tell us what to do. And we’ll do it.”

Joe Bockerstette: You need to be open to the idea that maybe you don’t know it all and there is a better way. And there are professionals in this area who’ve been there, done that, seen the difference and know what it takes to succeed. I’ll give you one more quick, as an example.

Dr. Jeremy Weisz: Yeah, go ahead.

Joe Bockerstette: I had another client that called and said, “Will you guarantee savings, because we have other consultants who will guaranteed savings.” And my response is, “We’re not talking about 20% labor reduction here. We’re not talking about 20% inventory reduction. We’re talking about 500% EBITDA improvement over five years. The results are incredible if you take the learnings, implement the change and follow through. And we’ve got illustrated examples that support that. And so the idea that you’re not looking for a little bit here and a little bit there, you’re looking for things that move the needle in a substantial way. And you’re looking for sustainability over a period of time.”

Dr. Jeremy Weisz: Yeah. So how do you answer that?

Joe Bockerstette: My answer to that, well, I have two answers.

Dr. Jeremy Weisz: It depends on you executing on what we tell you.

Joe Bockerstette: Well, three answers. One answer was, we’ve been in business since 1993 without ever doing that once. We’re not going to start now. Number two, the success of this is far greater dependent on you than me. And number three, anybody can find 20% savings. It’s just not that hard to do. And we’re not out for 20% savings. We’re out to make you a better enterprise over many years.

Dr. Jeremy Weisz: Yeah, I imagine…

Joe Bockerstette: It’s not over yet.

Dr. Jeremy Weisz: Yeah. Imagine going from 60 days to one day, how much efficiency, labor costs, you could sell more product. I mean, there’s just so many across the board benefits to that.

Joe Bockerstette: The extrapolated effects are enormous. And when you stack this on top of their improvement over two, three, five, seven years, at some point you gain a competitive advantage that’s almost unfair because you become so much better operationally. And this isn’t just about manufacturing. We’ve done retail, we’ve done administrative, we’ve done virtually every kind of business possible. And the fundamentals are the same regardless of your type of industry.

Dr. Jeremy Weisz: I wonder if you’d talk about Business Enterprise Mapping and some of the things that you do there.

Joe Bockerstette: The primary difference in the way we deliver our services is we are a partnership model. We are facilitators of workshops who maximize the knowledge of your employee base to better understand and improve your business. We fundamentally believe those who do the work should diagnose, design and improve the work. And the idea of industry expertise is really overrated. It’s not that hard to find out what’s wrong. All you got to do is ask people doing the work what their problems are. It really generates very quickly an 80/20 concept of the opportunities and what needs to be done to address them. And then we have this very structured methodology being processed, people, you might imagine, we’re very fast at what we do. We’re very effective at what we do. We deliver very consistent playbooks and diagrams. And so we’ve perfected a way to diagnose process-based opportunities in an organization very efficiently, effectively. And we’re able to use that knowledge from such a wide, wide variety of examples to benefit the client we’re working with.

Dr. Jeremy Weisz: Yeah. It’s amazing, some of the smartest people I’ve talked to and someone like you, it comes down to talking to your staff and talking to the customers, right?

Joe Bockerstette: Right. We have found that the more sophisticated the tool, the more likely you’re not going to need it, honestly. Let’s just get the person in the room or the group in the room that executes that process. Let’s get it documented. While we’re documenting, tell us what your problems are. And the big hitters are always cross-organizational. The big hitters are always convoluted workflows. The big hitters are always too many people being involved. It’s not that hard. Big hitters are always not measuring the right things as an example of a very, very common problem in opportunity. And we identify what we call quick wins, which are problems you can solve in 90 days at the process team level. And we know from experience, that’s about 50% of all opportunities that clients bring to the table.

Dr. Jeremy Weisz: I love it. And you have a body of work people can check out, businessmapping.com resources. I wanted to go through one… One piece was interesting on your site, which is, for this conversation, types of process measures. And so you talk about value proposition, effectiveness, resource productivity, conversion efficiency, customer alignment, cycle time, third-party compliance, process value. I was wondering, maybe just break down one of those, and people can check out the full article, but maybe just break down one of those seven types for people. What should we start with?

Joe Bockerstette: That’s tough to do. Let’s start with effectiveness. So effectiveness is the extent to which the value proposition of your product and service delights your customer. And a value proposition is the tangible deliverable itself; the service, the time, the cost. The value proposition is broader than just what you’re delivering. And we would tell you that effectiveness always comes before efficiency. And so if you don’t deliver an effective value proposition from your process, the rest of it doesn’t matter. Now, folks get the idea of value proposition and delivering to external customers, very few think about the value proposition of an internal process. The value proposition of a purchasing process is to deliver a purchase order to a vendor that is accurate, complete, and timely. If the vendor doesn’t have good information from the customer, they are not likely to deliver a good product or service in return. And that’s just one small example.

Dr. Jeremy Weisz: Yeah.

Joe Bockerstette: Let me go to the other end.

Dr. Jeremy Weisz: Yeah, keep going.

Joe Bockerstette: Let’s go to value. So value is a misunderstood metrics. A value measures the value delivered by that process relative to the cost of that process. And so when you think about a tangible manufacturing product, that’s easy to address. I’ve got a cost of goods sold and I’ve got a price. The customer is willing to pay for that. And that represents the value of that product, of that process. But let’s go to an internal. Let’s take a financial statement which we talked about at the beginning. So a financial statement is a primary deliverable of the accounting business system. The financial statement has a cost attached to it. People don’t think of it that way, but it’s got an input cost, a conversion cost, an overhead cost and the delivery cost. And so the question is, we’re producing let’s say one financial statement a month, 12 a year, and when we go into the cost assignment to that process, those 12 a year might be costing us, I don’t know, $1,500 a statement.

Joe Bockerstette: And so does the value delivered by that deliverable outweigh the cost of that deliverable to the enterprise? Now in an internal process, you don’t have a price, so it becomes an intangible assessment. I need financial statements. Am I willing to pay $1,500 per statement? Or maybe I should be paying $150 per statement.

Dr. Jeremy Weisz: Most people don’t think like that.

Joe Bockerstette: That’s right. And that’s what process-based thinking does. And that’s what the paradigm shift provides. I can cost any process in the world using the same formula. The elements are going to be different, but the principles are the same.

Dr. Jeremy Weisz: Yeah. So Joe, in that case would some people like, “Yeah, it’s not that important, we don’t need it.”

Joe Bockerstette: It depends on what you’re trying to accomplish. Folks bring us in for a variety of reasons. When it is a cost-based reason then it is important to understand what that process is costing me. We will find entire processes that are non-value-added customer credits, as a good example. The entire process is built around a failure in a previous process. And so the question is, what is the cost of that process? How many deliverables are you providing? And what opportunity does that provide the organization for a cost reduction and a quality improvement by eliminating the need for that non-value-added process completely?

Dr. Jeremy Weisz: Yeah. So, you’ll help people just cut out tons of waste or discover the waste also.

Joe Bockerstette: Discover the waste. It’s really about discovering the waste and identifying what needs to change in order to take that waste out. We know from experience that about 70% of all problems are processed efficiencies. Either the process is undefined, wasteful and inefficient or about 20% are in the boundaries between processes where we’re having a failure of handoffs.

Dr. Jeremy Weisz: Yeah. First of all, Joe, thank you. Thanks for sharing your knowledge, your expertise. I want to encourage everyone to go to businessmapping.com. Anywhere else we should point people towards online or on your site? Obviously you could check out their blog and we just talked about one of the seven types of process measures. Anywhere else we should point people towards?

Joe Bockerstette: Nope. That’s good. You can find us there.

Dr. Jeremy Weisz: All right. Thank you so much.

Joe Bockerstette: Jeremy, thank you. It’s been a pleasure.

Speaker 1: Thanks for listening to the Process Breakdown Podcast. Before you go, quick question. Do you want a tool that makes it easy to document processes, procedures and/or policies for your company so that your employees have all the information they need to be successful at their job? If yes, sign up for a free 14-day trial of SweetProcess. No credit card is required to sign up. Go to sweetprocess.com, sweet like candy and process like process.com. Go now to sweetprocess.com and sign up for your risk-free 14-day trial.