Last Updated on March 5, 2025 by Owen McGab Enaohwo

Every company is in the business of creating value.

They change business inputs (raw materials, human resources, etc.) into outputs (final product or service) in a way that these outputs have greater value than the original cost of creating the outputs.

Several companies provide value in different ways. For example, manufacturing companies create value by buying raw materials and using them to create a useful product. Retailers bring together several products and present them in a way that suits the customer’s convenience and needs. The list goes on.

Your organization should be concerned about how much value it creates. The more value your organization creates, the more profitable it is likely to be. It also helps to build a competitive advantage.

How do you ensure that your organization provides the most value it can? Through value chain analysis.

In the next few minutes, I am going to walk you through what value chains are, the activities involved, their types, their benefits, and many more.

Just get settled. It promises to be an interesting ride.

Chapter 1: Understanding Value Chains

Chapter 2: Components of a Value Chain

Chapter 3: Categorization of Value Chains

Chapter 4: Benefit of a Value Chain

Chapter 5: Competitive Advantage

Chapter 7: Innovation Value Chain

Chapter 8: Supply Chain Versus Value Chain

Chapter 9: Challenges of a Value Chain

Chapter 10: Value Chain Analysis Template

Chapter 11: Outsourcing Value Chain Activities

Chapter 12: Today’s Impact on Value Chain

Chapter 13: Execute Value Chain with SweetProcess

Conclusion

CHAPTER 1: UNDERSTANDING VALUE CHAINS

Let me begin by introducing you to the world of value chains.

What is a Value Chain?

A value chain is a business model that describes a set of activities that an organization performs to deliver a valuable product or service to its consumers. These activities include the process of creating, commercializing, and correcting products or services.

For manufacturing companies, a value chain consists of the activities involved in bringing a product from inception to distribution.

Your organization could have multiple value chains. According to Heflo, most organizations support from three to 15 value chains.

The value chain system was first described in Tableau Economique, an 18th-century book written by Francois Quesnay, a French economist. It was, however, expanded by several experts like Robert M. Grant and Wassily Leontief.

Nevertheless, the value chain analysis was pioneered and illustrated by Michael Porter in his book titled Competitive Advantage: Creating and Sustaining Superior Performance, which remains an all-important methodology to date.

According to him, “Competitive advantage emerges from how a firm performs in designing, producing, marketing, delivering, and supporting. It cannot be understood by looking at a firm as a whole. Each of these activities can create a basis for differentiation and contribute to a firm’s relative cost.”

In other words, a company is supposed to maximize value at every step of the company’s production process.

What is Value Chain Analysis?

Value chain analysis refers to the process in which an organization identifies the activities that add value to its final product or service and then analyses these activities to see how the organization can create a competitive advantage for itself.

The goal is to increase production proficiency so that the organization can provide maximum value to its customers at the least possible cost.

Conducting a value chain analysis helps your company figure out areas of inefficiency in your business and implement strategies that optimize your procedures for maximum profitability and proficiency.

In the end, you leave your customers feeling satisfied enough to stay loyal to your brand.

To help you further understand the concept of value chains, their management, and analysis, watch this video:

Now that you have an idea of what value chain is and its analysis, it is time to dive deeper into understanding value chains and how they operate.

How does a value chain take shape within your organization’s process? Let’s find out next.

CHAPTER 2: COMPONENTS OF A VALUE CHAIN

When Porter wrote about value chains, he focused on systems and how inputs (raw materials, labor, energy, etc.) are changed to outputs. In his book, he described a chain of activities that every company goes through in the process of creating value for its customers.

He divided this chain into two major components: primary activities and support activities.

These components help create the equation for calculating margins. Margins are the revenue that is generated from a value chain.

Value created and captured – Cost of creating that value = Margin

What are these components about? Let’s find out, starting with primary activities.

Primary Activities

Primary activities are activities that are directly concerned with the creation and delivery of a product. These activities include every step in the physical creation, sale, and maintenance of a product or service.

They are very important in adding value and creating a competitive advantage. Primary activities include:

Inbound logistics

This refers to all the activities related to receiving, storing, and distributing inputs (raw materials and resources) internally.

It centers around how materials and resources are gotten from suppliers to create a finished product. Activities under inbound logistics can include supplier relationships, talent pipelines, transport of goods, inventory management, warehousing, etc.

While analyzing this, look at the location of your suppliers and how much it costs to ship materials from their facility to yours.

Operations

Operations is the process of converting the received inputs into valuable finished products for your customers. Your operations systems should ensure quality assurance and make sure the finished products satisfy the needs of your customers.

While making your analysis, look at the cost of assembly lines, running your warehouse, machinery, salaries, etc.

Outbound logistics

Outbound logistics involves the distribution of finished goods or services. These activities ensure that your product or service is delivered to your customer. They include the collection, storage, and distribution of the final products.

This distribution may be within or outside your organization. The finished product can be distributed to wholesalers, retailers, distribution centers, or the customer directly.

When analyzing, consider the cost of delivery to customers, your warehousing fees, your distributor relations, etc.

Marketing and sales

Marketing and sales describe all the activities your organization uses to influence customers to buy from your organization instead of your competitor. They focus on how you present and sell your product or service to your ideal market.

Marketing and sales are simply the marketing and selling of products.

These activities include benefits offered to customers, how well these benefits are communicated, and if these benefits are valuable to the customer.

In your analysis, take into consideration your advertising and promotional costs, your reach, your cost-per-acquisition, etc.

Service

Service refers to the services you offer to your customers after sales.

They often include support and training for the product, warranties, refunds, returns, add-on services, etc.

These services are aimed at keeping customers engaged, ensuring the product or service is working perfectly, and ensuring your customers buy from you repeatedly. They are designed to enhance customer experience.

When analyzing, look at product training cost, repair cost, product adjustment frequency, and more.

Now let’s move onto the second major component: support activities.

Support Activities

Support activities are activities that assist the primary activities in ensuring that your organization achieves a competitive advantage over competitors. They make the primary activities more effective and efficient.

Support activities include:

Infrastructure

Infrastructure sums up activities like finance, legal, accounting, regulation, general management, quality assurance, public relations, etc.

These are departments and functions that allow the organization to maintain daily business operations (make business decisions and manage resources effectively).

Your organization’s infrastructure is everything else that goes into creating a product or service that is not directly connected to the final product.

Human resource management

Human resource management refers to how your organization recruits, hires, motivates, rewards, and retains its employees. It focuses on human resources and people management.

Your organization has to recruit, train, and develop the right people for it to be successful. You have to pay them well and ensure their well-being.

This is extremely important for companies who are offering services that are provided by employees—for example, the airline industry. Your employees can give you a competitive advantage if they are properly managed.

Technology development

Technology development refers to all the software, equipment, hardware, procedures, and technical expertise that are used in the transformation of raw materials into finished products or services.

It is mostly used at the research and development stage. It includes activities like designing and developing manufacturing techniques, managing and processing information, and automating the organization’s processes.

To create value through technology development, you have to stay current with technological advances, minimize information costs, and maintain technical excellence.

Procurement

Procurement refers to the activities involved in acquiring the resources an organization needs. It refers to how the resources and raw materials for a product or service are sourced and how suppliers are found.

It is this department that makes decisions concerning purchases. It is closely related to inbound logistics and operations. The goal of procurement is to find quality supplies for production that fit into your organization’s budget.

Procurement activities include finding vendors, negotiating prices, and securing contracts for goods and services needed for production.

Linkages Between Value Chain Activities

The value chain activities are connected to one another. None stands in isolation.

Each value chain activity usually affects the performance and cost of the other ones. Linkages can exist between only primary activities and also between both primary and support activities.

Sometimes, an organization may reduce cost in one activity and consequently enjoy a reduction in another activity. Other times, they might experience the opposite.

Also, though primary activities add value directly to the production process, that doesn’t necessarily mean that they are more important than support activities. In recent times, activities like technological development mainly drive competitive advantage.

Every activity is important and needed.

Examples of a Value Chain

Several companies over the years have adopted the value chain and used it to achieve a competitive advantage. Here are some:

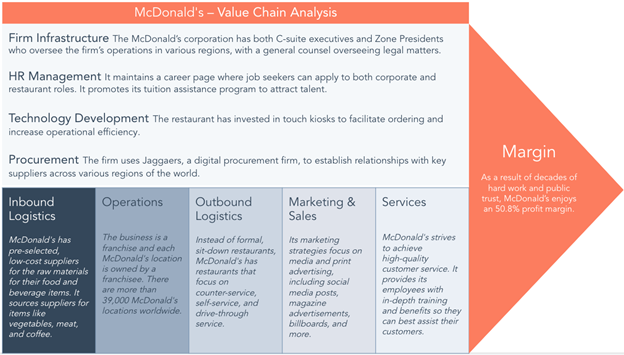

McDonald’s

Primary Activities

Inbound logistics: McDonald’s has low-cost suppliers of the raw materials used in producing their beverage and food items.

Operations: There are more than 39,000 McDonald’s locations across the world. The business is a franchise. Every location is owned by a franchise.

Outbound Logistics: Instead of being a formal, sit-down restaurant (which is the norm), McDonald’s focuses on self-service, counter-service, and drive-through service.

Marketing and Sales: McDonald’s focuses on media and print advertising as major parts of its marketing strategy. This includes social media posts, billboards, magazine advertisements, etc.

Services: McDonald’s strives toward delivering excellent customer service. Its employees go through in-depth training and are provided with benefits that help them assist their customers in the best way possible.

Secondary Activities

Infrastructure: McDonald’s has zone presidents and C-suite executives who oversee the operations of the business in several regions. They also have a general counsel who oversees legal matters.

Human Resource Management: Its website has a career page that gives room for job seekers to apply for both restaurant and corporate roles. McDonald’s pays both salaried and hourly rates to its employees. It also has a tuition assistance program which it uses to attract talent.

Procurement: McDonald’s uses a digital procurement firm to help the business establish relationships with key suppliers across several regions and countries in the world.

Value Chain Diagram Examples

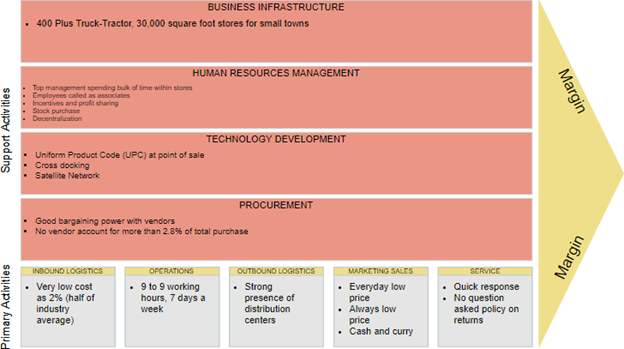

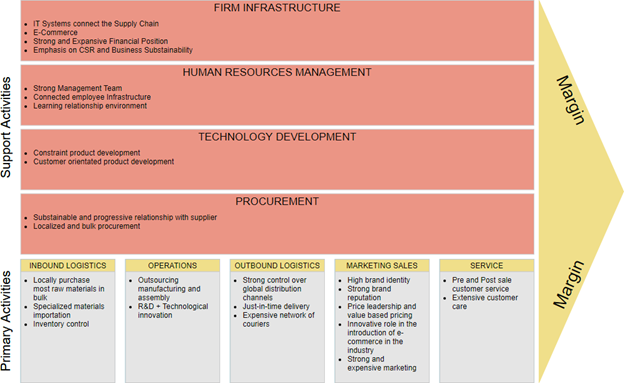

These diagrams below show how these companies make use of the value chain in their business processes to achieve competitive advantage:

Superstore Super Market

International Sportswear

Value chain is important for all businesses. For more examples on how a company uses value chain, go through this slide: Value Chain by Vyas Ashutosh. This slide shows how Asian Paint makes use of a value chain.

With these, you have an idea of what value chain looks like and the activities involved. The next stop is learning the types of value chains your organization can adopt.

CHAPTER 3: CATEGORIZATION OF VALUE CHAINS

Value chains are categorized based on how they are used within an organization and across several organizations:

Business-Unit Value Chains

Business-unit value chains focus on individual business units (departments, divisions, or functional parts of a company) instead of the entire organization. These value chains may integrate with other internal value chains within the organization.

Physical/Traditional Value Chains

Physical/traditional value chains are value chains that involve physical and tangible resources. This is usually used by manufacturing companies.

Firm-Level Value Chains

Firm-level value chains are value chains that are operated by an entire organization. They include all the activities carried out to ensure that the organization creates value in the delivery of its product/service.

Industry-Level Value Chains

An industry value chain captures the various processes involved in the production of goods and services within an industry, beginning with the raw materials used and ending with the delivered product or service.

Global Value Chains

Global value chains involve cross borders or regions.

This is usually adopted by multinational companies. They invest abroad and establish affiliates that provide support for the remaining activities done at the home location. Such value chains may include multinational trade agreements and partnerships.

Multinational enterprises locate the value chain activities in different countries around the globe to optimize profits and enhance efficiency.

Virtual Value Chains

Virtual value chains are value chains that involve electronic and virtual information.

This category was created by John Sviokla and Jeffrey Rayport. It describes how value-generating information services are disseminated within an organization.

This value chain starts with the supplier providing content, which is then distributed and supported by the information structure of the organization. It also supports the physical value chain of procurement, manufacturing, sales, and distribution.

Yes, there are different categories of value chains you can choose from. But why do you need a value chain in the first place?

CHAPTER 4: BENEFITS OF A VALUE CHAIN

Using a value chain offers a lot of benefits to your organization.

- It helps you identify key activities within your organization that can help you quickly reduce cost, eliminate waste, optimize effort, and increase profitability. This is possible because it requires you to break down product and service activities into small pieces, which helps you fully understand how they perform.

- It helps you reduce the cost of production while simultaneously increasing the value of your product/service.

- Analyzing the activities within your organization helps to achieve clarity around how your business works which, in turn, helps you make strategic decisions affecting your organization. It also helps you identify elements within the organization that bring greater value to the end-user.

- A value chain has the satisfaction of the consumer as its main focus. This helps you create a better experience for your consumers, create a more valuable product, develop loyalty, and ensure repeated purchase of your product/service.

- More importantly, a value chain helps you create differentiation from your competition. A well-optimized value chain gives you the edge over your competitors because it helps you create more value than they do.

These are some benefits of a value chain.

To fully understand how a value chain works, you need to understand what competitive advantage is and how the activities in the value chain can put your organization at an advantage.

This is what the next chapter is all about.

CHAPTER 5: COMPETITIVE ADVANTAGE

The whole essence of conducting a value chain analysis is to achieve a competitive advantage. It is what sets your organization apart from your competitors.

To achieve a competitive advantage, you need a clear picture of your target market and who your ideal customer is. You also need to know the benefit your product/service provides to your ideal customer.

When organizations create a value chain analysis, an organization aims to gain an advantage in two major areas.

Different Approaches to Achieving Competitive Advantage

There are two major approaches to achieving competitive advantage:

Cost Advantage

An organization can create a cost advantage by reducing the cost of specific value chain activities or by reconfiguring the entire value chain.

You can conduct a value chain analysis once the value chain is defined by assigning the cost of the value chain activities. The costs recorded may have to be modified to allocate them properly to the value-creating activities.

The goal of an organization when creating a cost advantage strategy is to become the lowest-cost provider in the market or industry. For a successful cost advantage strategy, you need to use low-cost materials and resources to reduce the overall price of the finished product/service. You also need to have extreme operational efficiency.

Porter identified ten cost drivers associated with the activities of a value chain:

- Economies of scale

- Learning

- Capacity utilization

- Linkages among activities

- Interrelationships among business units

- Degree of vertical integration

- Timing of market entry

- Firm’s policy of cost or differentiation

- Geographic location

- Institutional factors (union activity, regulation, taxes, etc.)

Your organization can achieve a cost advantage by controlling these cost drivers better than its competitors.

As I said, cost advantage can be achieved by reconfiguring the value chain. Reconfiguration here refers to structural changes like a different sales approach, new production processes, or new distribution channels.

For example, FedEx restructured its express freight service by purchasing its planes.

Differentiation

A differentiation strategy results in you having a unique or highly specialized product or service. It allows your organization to set a premium price for a product and service.

Differentiation stems from uniqueness. A differentiation advantage can be achieved by changing specific individual activities in the value chain to increase the uniqueness of the final product or service.

This advantage can come from any part of the value chain. For instance, procurement of units or materials that are unique and not readily available to competitors can create a differentiation advantage.

Your business also needs to dedicate time and resources to research, innovation, and development. Identify the activities that create the most value to customers and evaluate strategies to improve the value of less valuable activities.

You should focus on customer service, offering incentives, increasing options to customize products and services, and adding unique product/service features.

There are several drivers of uniqueness:

- Policies and decisions

- Linkages among activities

- Location

- Interrelationships

- Learning

- Integration

- Scale

- Institutional factors

Many of these drivers are also cost drivers.

Technology and the Value Chain

Technology is an important factor in a value chain.

Technological changes can affect competitive advantage. It can change the activities in the value chain or make new configurations of them. This is possible because technology is used, to some degree, in activities that create value.

Several technologies are used in carrying out both primary and support activities. Areas where technology is used include:

1. Inbound Logistics Technologies

- Material handling

- Testing

- Information systems

- Material storage

- Communications

- Transportation

2. Operations Technologies

- Materials

- Process

- Testing

- Machine handling

- Packaging

- Maintenance

- Machine tools

- Information systems

- Building design and operation

3. Outbound Logistics Technologies

- Material handling

- Transportation

- Communications

- Packaging

- Information systems

4. Marketing & Sales Technologies

- Audio/video

- Media

- Information systems

- Communications

5. Service Technologies

- Communications

- Testing

- Information systems

Furthermore, support activities frequently make use of technologies in relation to training, software development, and computer-aided design.

Porter’s Five Forces That Influence Competitive Advantage

Before Porter wrote about the value chain models, he created a unique competitive analysis tool which he named Porter’s Five Forces.

Porter’s Five Forces looks critically at the competitive market forces to identify risks or opportunities. It is similar to SWOT (strengths, weaknesses, opportunities, and threats) analysis. It analyzes changing conditions and environments to provide a business structure for proactive improvement.

The Porter’s Five Forces are:

- Competitive rivalry within the industry

- The threat of new market entrants

- Bargaining power of customers

- Bargaining power of suppliers

- The threat of substitute products

This analysis extends beyond just identifying competitors. Instead, it is centered around how the behaviors and relationships of your competitors put pressure on your organization. This helps you assess your organization’s true market position, overcome challenges, and figure out ways to overtake your competitors.

Improvements that might occur include cost and innovation containment opportunities, the use of unique raw materials and manufacturing processes, improved locations for ease of delivery, and exclusive supplier agreements.

Achieving competitive advantage is great, but first, you need to know how to use the value chain. Keep on reading to find out.

CHAPTER 6: USING VALUE CHAIN

This chapter explores what you need to know about using a value chain. Let’s get started.

Who Uses a Value Chain?

The analysis and management of value chains are becoming both industry-specific and global. They take into account adjustments necessitated by new technologies, fast-changing markets, delivery methods, trade and government involvement, and customer demands.

Business leaders continue to implement Porter’s value chain framework successfully. Various departments, as well as companies and industries, use a value chain, not to mention governments and world agencies.

The reason why many businesses have successfully used this framework is that it is a general one. It is not a standalone framework, nor is it a rigid framework.

Value Chain Analysis Steps

How do you go about your value chain analysis? Here are steps to take when conducting your value chain analysis:

1. Identify your organization’s primary activities and their subactivities

First, you need to identify your organization’s primary activities. Next, for each primary activity, you determine the specific sub-activities that create value.

According to mindtools.com, there are three types of sub-activities:

- Direct activities

Direct activities are activities that create value by themselves. For example, in the marketing and sales activity of a book publishing house, the direct sub-activities include advertising (both digitally and offline) and making sales calls to bookstores.

- Indirect activities

Indirect activities are activities that allow direct activities to operate smoothly. For the book publishing house, the indirect activity for the sales and marketing activity includes keeping customer records and managing the sales team.

- Quality assurance

Quality assurance activities are both the direct and indirect sub-activities that meet the right quality standards. For the book publishing house, this could include editing and proofreading advertisements (both online and offline).

2. Identify your organization’s support activities and their sub-activities

Just like you did for your primary activities, identify your support activities. Determine how they support the primary activities. For example, determining how procurement adds value to inbound logistics, operations, outbound logistics, etc.

After that, determine the indirect sub-activities for each support activity. Look for the direct, indirect, and quality assurance sub-activities.

3. Identify links between these activities

Point out the connections between the activities that you have identified. For example, there is a link between service phone calls from frustrated customers awaiting their package deliveries and order turnaround times.

This might be time-consuming, but these links are important to increasing competitive advantage.

4. Analyze the value and cost of these activities

The team in charge of creating your organization’s value chain should brainstorm ways each activity provides value to your business as a whole and your customers.

Compare each activity to the competitive advantage you are trying to achieve (whether cost or differentiation), and then see if it supports your goal.

Once the value analysis is complete, look at the cost of the activities. This will help you identify which activities are cost-effective and those that are not. Look for areas of improvement for activities that are not cost-effective.

5. Identify opportunities to increase value

Once you’re done identifying the important areas, it is easier to see the areas of the business that are excelling and those that need improvement.

Start with improvements that require minor changes but will yield high-impact results. After working on the easy wins, you and your team can begin to tackle the bigger challenges.

To make your analysis even easier, there are value chain resources you can access for more help or information. These are what we will be exploring next.

Value Chain Resources

There are several value chain resources—professional organizations, methodologies, best practices, and tools. You can check out these resources for a more robust idea about value chains and the activities it involves.

Here are some of them:

- Supply Chain Organizational Reference (SCOR): SCOR is a reference model for the activities that are associated with Porter’s value chain model—activities like planning, supply chain, procurement, manufacturing, logistics, order management, returns/retail, research, prototypes, integration, launch, service support, sales, CRM, after-sale service, and contract management.

- The Supply Chain Council: This is a global association with over 700 organizations under its umbrella that manage the SCOR.

- DCOR (Design Chain Operations Reference): DCOR is a process framework that is used for developing processes, practices, and metrics into a unified structure. The US Department of Defense (DOD) has adopted this newer model. The DOD does not focus on marketing or sales in its value chain.

- The e3 Value Methodology: This is an approach to creating business models across several networks of customers, suppliers, and suppliers of suppliers.

- HoloMapping® and ValueNet Works™ analysis: This analysis was developed by Verna Allee. It provides a systematic understanding of the value network.

Departments and Industries That Use Value Chain Modeling

Porter’s value chain can be adapted to a host of industries, and it can be applied to any company, especially one that is in a highly competitive industry and wants to save costs and achieve differentiation.

Industries

Examples of industries that use value chain modeling include:

Delivery Service

Delivery service providers like UPS, USPS, and FedEx invest in services and infrastructure that will control cost, speed up delivery, and manage capacity.

Their value chain models give room for them to analyze logistics related to the delivery of goods in a complex environment that is affected by third-party suppliers, transportation regulations, and storage locations.

Food and Beverage

The value chain model for the providers of food and beverage has a flow that starts with sourcing materials and ends in consumer consumption.

For instance, Starbucks starts with the cost and processes that are related to coffee bean sourcing, continues with the customization of coffee beverages, and finally, delivers to the customer.

Online and Brick-And-Mortar Retail

The retail value chain clearly defines actions that make it easy for companies like Walmart and Amazon to sell goods to customers. It allows them to monitor each action throughout the value chain, from product creation to storage to the distribution of customers.

Walmart, for example, constantly evaluates supplies to keep costs low for the customers. Amazon, on the other hand, focuses on being the most consumer-centric company, and it constantly looks for an improvement to meet its mission.

Companies

Companies that use value chains are the “who’s who” of the world’s marketplace. They include big names like McDonald’s, Starbucks, Rolls-Royce, etc. This, however, does not mean that the use of the value chain is limited to those companies.

Value chains are used by companies in different industries, including communications, banking, farming, and so on.

Departments

Apart from companies and industries, interdependent departments within an organization also make use of value chains. These departments include marketing, sales, customer service, human resources, procurement, cooperative value systems, IT, etc.

Examples include:

- CRM Value Chain

This involves the costs and processes that are associated with the customer journey. Customer relationship management (CRM) value chain focuses on the customer’s interaction and points out opportunities that will enhance customer relationships and value.

- Brand Value Chain

This value chain identifies differentiation (both tangible and intangible) that helps you secure and enjoy the benefits gained from a strong brand identity and its extremely high market value.

World Organizations

You should note that government, humanitarian organizations, and world agencies also make use of value chains to identify and optimize value propositions that are specifically created to fight against poverty, build infrastructure, provide economic relief, all while honoring unique cultural practices.

Tomato farmers in Ghana, for example, benefit from value chain analysis which includes access to credit, improved cultivation practices, government interference, and geography.

For more information about how you can use value chains in your organization, take a minute to watch this video:

You can take your value chain analysis up a notch by creating an innovation value chain. How can you do that?

CHAPTER 7: INNOVATION VALUE CHAIN

One key component of a fully optimized value chain is innovation.

You should constantly be searching for innovative ideas that will make your value chain more valuable. Look beyond the organization for new concepts and partners. This will put you way ahead of your competitors and increase your profit margin.

However, before implementing new ideas, it’s crucial to conduct a SWOT Analysis to assess your organization’s internal strengths and weaknesses, as well as external opportunities and threats. This structured evaluation ensures that your innovation strategy aligns with your company’s core competencies and market dynamics.

You can’t just import innovative ideas to solve your organization’s problems. Instead, you have to consider your organization’s existing processes for creating innovation, pinpoint the specific challenges, and develop ways to solve the problems. The innovation value chain can help you achieve this.

What Is an Innovation Value Chain?

According to the Harvard Business Review, the innovation value chain presents innovation as a sequential, three-phase process that involves idea generation, idea development, and the diffusion of developed concepts.

As a manager, you have to perform six critical tasks across all phases. They include internal sourcing, external sourcing, cross-unit sourcing, selection, development, and company-wide spread of the idea. Each of these tasks is a link within the chain.

This framework—the innovative value chain—centers the manager’s attention on the weakest links in the organization’s chain. When managers focus on the strongest links within the innovation value chain, they further weaken the weakest parts of the chain, which compromises the overall innovation capabilities.

Different Phases of the Innovation Value Chain

You have to view the process of transforming ideas into finished outputs as an integrated flow if you want to improve innovation.

The first of the three phases in the innovation value chain is to generate ideas. Ideas can be generated within a unit, across units in an organization, or outside the organization. The second phase is to convert ideas. This involves selecting ideas for funding and developing the ideas into finished products and services. The last phase requires you to diffuse the products and services.

Let’s look at the activities involved in each phase.

Idea Generation

Innovation starts with great ideas. But the question is, “Where do great ideas come from?”

Many managers look within their business units for creative sparks. The bigger sparks are usually ignited when fragments of ideas come together, especially when individuals across different units brainstorm or when the organization seeks ideas from external partners.

However, combining ideas from different parts of an organization to develop new products is not easily achieved. This is because of the decentralized organizational structures of some companies and their geographical dispersion. These make it hard for people to work across units.

Organizations need to check if they are getting enough good ideas from outside the organization or even outside the industry. Your organization can tap into the knowledge and insights of customers, competitors, end-users, independent entrepreneurs, universities, inventors, investors, scientists, and suppliers. Many organizations do not do this well, and this leads to missed opportunities and lower innovation productivity.

For example, Sony, which was known for developing new products like the PlayStation and Walkman in the 1980s, experienced an innovation lag in the 1990s. In a 2005 New Yorker article, Sir Howard Stringer recalled that they began to suffer from “not invented here syndrome.”

They had the belief that outside ideas were not as good as in-house ones, so they did not follow suit even when their rivals were introducing next-generation products like the Xbox and iPod. They missed several opportunities in developing new technology products. Instead, they developed unwanted products.

Idea Conversion

Great ideas are useless if they are not properly managed.

You need strong screening and funding mechanisms for new concepts to prosper. If not, they will yield headaches and challenges. Many companies shut new ideas down because of tight budgets, strict funding criteria, and conventional thinking. This can lead to the flow of ideas from employees stopping.

For example, in 1999, when Stewart Davies became the head of R&D, the UK telecommunications group had financial problems. After reviewing operations at R&D at BT, he was shocked by the inventiveness and the frustration of the employees. The problem was not a shortage of ideas but inadequate commercial skills and a shortage of funding for high-risk projects.

For some other companies, the problem is that managers do not properly screen these ideas. The organization becomes filled with several new projects, which are usually understaffed and underfunded. There is no clear sense of how the new initiatives fit into the overall corporate strategy. This eventually leads to huge capital loss, and sometimes, businesses have to shut their doors.

No matter how well funded or screened these ideas are, they need to be turned into revenue-generating processes, products, and services.

Idea Diffusion

After an idea has been sourced, screened, funded, and developed, they still need to receive buy-in, and not just by customers alone.

You should get the relevant departments within your organization to support and spread new products, services, practices, and business across preferred geographical locations, customer groups, distribution channels.

However, diffusion is far from automatic for large organizations with many subsidiaries. For example, Procter & Gamble in Europe focused on extensive product and marketing testing. They placed the final authority for launching new products on its national brand managers. This resulted in really slow rollouts.

Because of their intense market-testing requirements, they launched Pamper’s diapers in France five years after they launched in Germany. During that period, Colgate-Palmolive launched its line of diapers in France and gained a dominant market share.

Focus on the Right Links for Your Business

Many managers are quick to focus on their innovation strengths. But these strengths can lead to weaknesses in the organization’s process if they are not properly complemented by equal strengths in other parts of the chain.

When you focus more resources and time on a link that is strong already, and you fail to recognize the weak links, you undermine your organization’s overall innovation efforts.

In the same vein, your organization’s strongest links are no good if paying attention to them weakens other links in the innovation chain or if they require the organization to spend money with little hope of returns.

As a manager, you should focus on strengthening your weak links.

Fixing Innovation Issues Within a Company

There are three typical weakest-link scenarios that most companies face. Discussed below are the best practices you can adopt to fix these weak links.

How to Fix an Idea-Poor Company

One of the reasons why many companies experience a shortage of good ideas is because they have inadequate networks.

Managers do not forge quality links with people outside their company. Also, employees prefer to talk to their immediate teammates rather than speaking to their colleagues in other departments or divisions.

Your organization must build internal cross-unit networks as well as external networks so you can generate new ideas from new connections.

How do you do that?

Building internal cross-unit networks

You need to build cross-unit networks within your organization.

Your employees need to know one another to be able to collaborate on new ideas. The cross-functional brainstorming sessions held occasionally will not do the trick. What you need to do is develop an ongoing dialogue and knowledge exchange between employees from different units in the organization.

You should bring together people from different parts of the organization with varying areas of expertise. These collaborations do not happen by chance. They are fueled by a well-established organizational mechanism.

Create a healthy environment where employees can continuously talk about problems and brainstorm solutions to those problems.

For example, P&G developed 30 communities of practice. Each community has volunteers from different parts of the organization and their areas of expertise.

These communities solve specific problems brought to them, and they participate in monthly technology summits. P&G also has an “Ask me” feature on its intranet, where employees pen down business needs and problems. Also, the organization moves its people across units and countries and promotes from within. This helps employees build extensive cross-unit networks.

Building external networks

There are two approaches to building external networks.

The first approach is to develop a solution network that is geared toward finding answers to specific problems within the organization.

For example, Eli Lilly, the pharmaceutical company, managed InnoCentive. This is a solution-oriented website that Lilly and other similar companies use to find answers to specific scientific and technical issues. The companies post questions that are answered by over 10,000 chemists, engineers, and other scientists that are registered at the site.

The second approach is to build a discovery network aimed at discovering new ideas within product domains and broad technology. The aim of discovery networks should be to learn and not to teach.

Whether you are creating solution networks or discovery networks, the important thing to put in mind is diversity—of contacts, not numbers. The main goal is to access as many unique sources of ideas and information as possible instead of interacting with the same or similar contacts.

How to Fix a Conversion-Poor Company

This answers the question, “Why do companies find it hard to convert good ideas into products and services?”

Many companies have formal systems for managing ideas. However, the number and diversity of people involved in the processes can make the processes bureaucratic, which brings the execution of the systems to a halt.

Two innovation practices can help solve the conversion problem. They include:

Multichannel funding

Innovation is stifled in conversion-poor companies when, for instance, the boss doesn’t like a new idea and does not consider it good enough to replace an existing project that is already accounted for in the company’s budget. And that usually leads to the death of that idea.

Adopting a multichannel funding model gives room for different funding options, from small discretionary funds to full-scale venture funds. It requires you to have several funding sources for your projects or new ideas.

Safe havens

You should create safe havens for emerging concepts in your organizations, so they do not die halfway into the conversion process.

For example, a UK technology company established a separate unit that focused on developing new business ideas. This unit shielded the new businesses from the budget restraints that affected the rest of the organization, but without isolating them. These businesses were sited in a new location and given high levels of operating autonomy.

The UK company also developed a compensation scheme for the managers of these businesses. Their pay was low compared to standard industry salaries. However, if they hit all their numbers, they got rewards as high as the main company’s senior executives.

Out of the 13 new businesses that were sheltered, nine became viable businesses with combined annual revenue of over £100 million.

How to Fix the Diffusion-Poor Company

This section answers the question, “Why do companies find it hard to gain traction for their new ideas?”

In many decentralized companies, managers have considerable autonomy and can reject new ideas. Even in organizations where the managers do not have that much control, they can still sabotage or delay the projects they do not believe in.

An organization’s executives cannot just order a rollout of developed ideas throughout the organization. What they should do instead is to create buzz for new ideas by using catalysts.

One of the catalysts you can use is the “idea evangelists.” These are people who preach the good word about a new product or business. They use their deep personal networks to relentlessly increase awareness among employees and persuade them to adopt the new product or business idea.

They do this through emails, sales calls, phone calls, and meetings. These evangelists should have relationships spanning many parts of the organization.

Create New Measures and New Roles

You should tailor your solutions to the right problems. Over time, the weak links in the innovation chain will become strong ones.

You also need to implement key performance indicators that focus on individual deliverables from each link in the innovative value chain.

For instance, if an organization wants to improve its external sourcing of good ideas, a good measure metric would be the number of new good ideas the company sourced externally the previous year, rather than the number of partnerships it has created.

You also need to create new roles for employees. For example, Siemens, in Silicon Valley, lets team members take on the role of external scouts who seek good ideas from outside the company.

There are a lot of books and consulting firms from which you can seek to improve your innovation capabilities. Keep in mind, however, that one size doesn’t fit all. If you apply popular innovation remedies inappropriately, you may sabotage your efforts to improve.

But if done properly, an innovation value chain allows you to unveil a stream of new products and services to your target market. More importantly, it can help you realize the potential of your innovation investments.

CHAPTER 8: SUPPLY CHAIN VERSUS VALUE CHAIN

A supply chain refers to the entire process of creating and selling goods and services, including every stage, from the supply of raw materials and the production of the product to the distribution and sale of the product/service.

A supply chain is quite similar to a value chain. However, a value chain considers more things.

A supply chain considers the parts or materials that go into creating a product, where a product/service is produced, the transportation logistics in taking it from the factory to the store, and the final delivery to consumers.

A value chain, on the other hand, puts into consideration activities like product design, advertising and other marketing strategies, research and development, and even the work of experts like accountants, IT experts, and bankers that make the creation of a product possible.

Basically, a value chain is more robust than a supply chain.

For more information about the differences between supply chain and value chain, please watch this slide:

A properly implemented value chain can yield a lot of benefits. Nevertheless, there are challenges you have to deal with along the way.

CHAPTER 9: CHALLENGES OF A VALUE CHAIN

A value chain is not an easy feat, and here are a few reasons:

- It is not static. It requires constant attention, evaluation, and updating to ensure business progress. You have to ensure that your value chain is constantly updated to adapt to new realities. Your value chain has to keep pace with evolving technology, adapt to the changing workforce, and expand with the global economy.

- A value chain also requires you to identify thousands (depending on your process) of direct and indirect activities that can impact your value chain and its performance. This is a huge task, especially when you have to keep track of all of them.

- The value chain model does not put into account the individual needs of individual organizations and industries. Because of this, identifying tasks, developing plans, and adapting the model to suit your individual needs can be extremely time-consuming.

- It is not always easy to find the right information to break your value chain into primary and supporting activities. Also, breaking down your organization’s operations can make you lose sight of your strategic objectives.

- The value chain model was created before the internet came into being. While it can be adapted to suit digital business, the fit is sometimes not perfect.

CHAPTER 10: VALUE CHAIN ANALYSIS TEMPLATES

Below are a few value chain analysis templates that can guide you in developing a value chain that suits your organization’s needs:

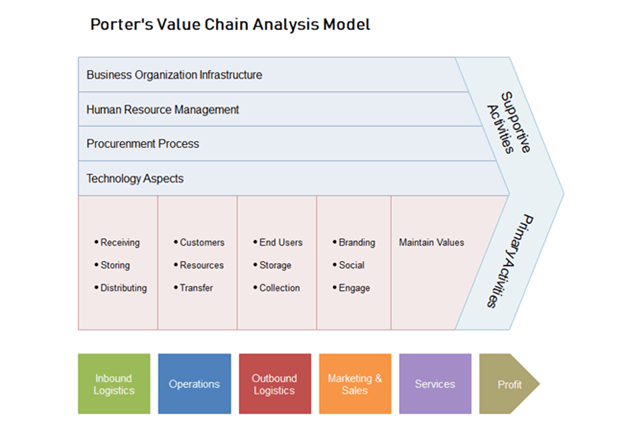

Porter’s Value Chain Analysis Model

This template provides a general overview of the various activities within an organization.

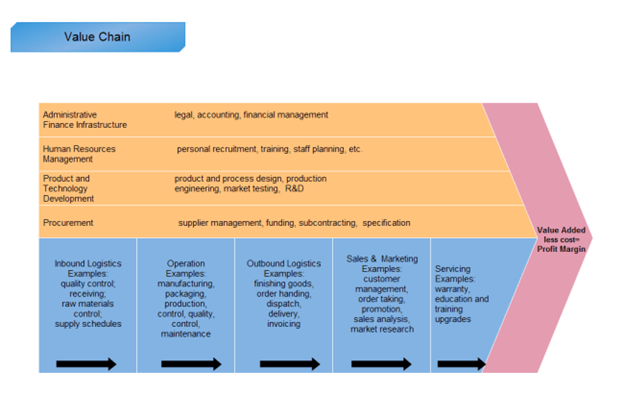

Template for Cost Profit Margin

This template will help you analyze the cost versus expected profit margin from your primary and support activities.

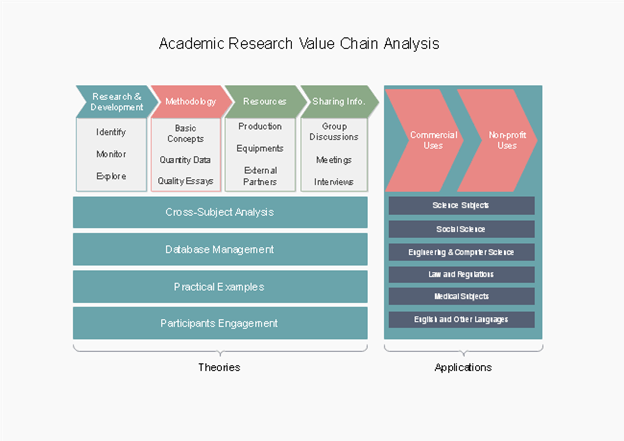

Template for Educational Institutions

This value chain takes a detour from the usual activities for creating a product or service. It focuses on the activities involved in developing academic research.

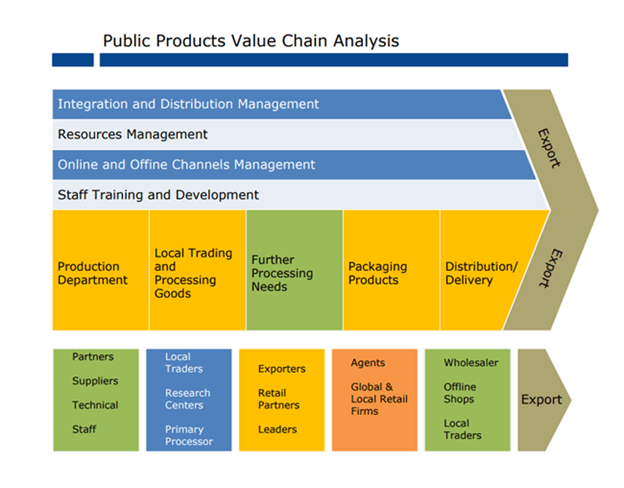

Template for Products

This value chain focuses on the activities involved in creating a product, from the raw material into a finished product.

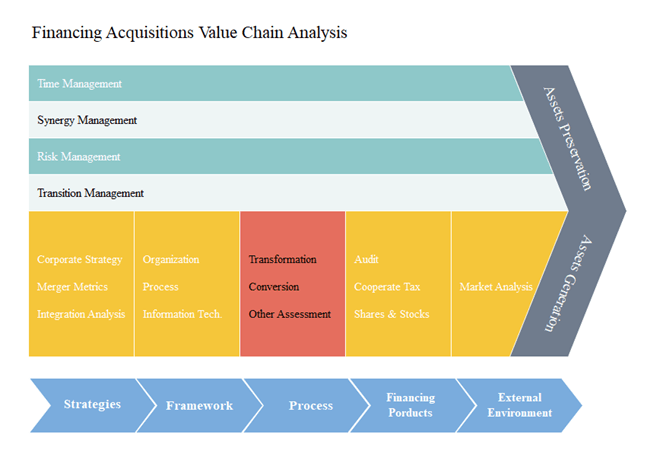

Template for Financial Acquisitions

This template guides you through the activities involved in acquiring a business or merging with another business.

These templates will guide you in creating your own value chain. Did you know that you can outsource your activities instead of taking on the full strain?

CHAPTER 11: OUTSOURCING VALUE CHAIN ACTIVITIES

Your organization can specialize in one or more value chain activities and then outsource the other parts of your value chain business processes. You do not have to handle everything by yourself.

You must understand your organization’s strengths and weaknesses in each activity in terms of cost and differentiation. This will help you decide which activities you need to outsource.

If you choose to outsource your value chain activities, here are some things you should consider:

- If the activity will be performed better or cheaper by the suppliers.

- If the activity is one of your organization’s core competencies, that can yield cost advantage or product differentiation.

- If the activity relies on technology that is constantly changing, or if the product is sold in a rapidly changing market. If this is the case, it is beneficial to outsource the activity. This helps you maintain flexibility and evade the risk of investing in specialized assets.

- If outsourcing the activity will result in business process improvements like higher flexibility, reduced inventory, reduced lead time, and so on.

If the activity checks these boxes, then you can outsource it.

There are a lot of changes happening in our current world that you should put into consideration in your value chain analysis.

We will explore those next.

CHAPTER 12: TODAY’S IMPACT ON VALUE CHAIN

Many organizations manage both virtual and physical value chains.

Using value chain analysis in the present day requires that you use the value chain to fit the ever-evolving business environment. Factors you should consider when analyzing and adapting value chains include infrastructure and technology needs, customer service experiences, personnel training, etc.

To properly reinvent the basic value chain, you have to study rapid technological changes.

Also, consider the fact that in recent times, the customer is more involved in product/service development. Questions about increased urbanization, the changing expectations of the consumer, and the rise of online shopping are now as valuable as the cost of the raw materials, the delivery of a product, and warehousing.

As new and unknown technology emerges, your organization’s value chain needs to be re-engineered—continuously. The adaptation of the basic value chain to the 21st century is seen as a journey of transformation. With this approach, value chain analysis will continue to remain a relevant tool to achieve competitive advantage.

CHAPTER 13: EXECUTE VALUE CHAIN WITH SWEETPROCESS

The creation and execution of your value chain becomes very easy with SweetProcess.

Not only does SweetProcess make the process easy, but it also saves you time and improves efficiency throughout the entire value chain process.

How does SweetProcess help in the creation of a value chain?

With SweetProcess, the ideation and creation stage of the value chain becomes easy. It provides you and your team with:

Collaboration tools to foster teamwork and engagement

SweetProcess allows you to hold meetings and have conversations regarding your value chain virtually—no matter where you are. So, the value chain process never stops or gets disrupted because of distance or lockdowns.

SweetProcess also allows team members to suggest improvements and gives the team leader the power to approve them. You can also easily assign tasks and track them until they are completed.

Unified knowledge base for easy access to information and speedy decision making

You can also create a private or public “knowledge base” where all your research, findings, and conclusions can be imputed. This makes it super easy for everyone in the team to access the right information when needed. This will also speed up the decision-making process and help you easily adjust the basic value chain to fit your organization’s peculiarities.

The use of diagrams and process maps to bring your value chain to life

You can bring your value chain to life with the help of beautiful illustrative diagrams within the software. You can create and design your value chain from scratch without the help of a template. You can also create workflow process maps for each activity within the value chain.

How does SweetProcess help in the execution of a value chain?

SweetProcess can help you with the execution of the activities within your value chain. It plays a great role in improving efficiency while executing every activity in the value chain.

Here are some examples of how SweetProcess can help execute your value chain activities:

Human resource management

Your human resource management efforts get a lot easier with SweetProcess. You can easily onboard and train new employees with the software.

SweetProcess also fosters teamwork with its team collaboration tools. This aids intra- and inter-departmental relations within the value chain. With SweetProcess, you can keep track of the activities of your employees and their progress.

How about seeing SweetProcess in HR management action?

Let’s check out how SweetProcess helped Forest Incentives boost employee performance with a central knowledge base.

Mr. Matthew Louridas, director of operations and client services at Forest Incentives, was constantly worrying about inefficiency within the organization.

However, with the help of SweetProcess, he was able to create easy and automated documentation of important information, streamline his business processes, create an accessible and centralized knowledge base for his employees, which sped up and improved their performance. This also ensures effective collaboration among his employees, which, in turn, increases productivity.

Inbound and outbound logistics

For both inbound and outbound logistics, SweetProcess helps you to effectively combine each sub-activity within these activities and make them an overarching workflow. You can create every step of the procedures needed with illustrative diagrams, keep everyone abreast of what is required of them, and track the progress of every activity.

Operations

SweetProcess also helps you efficiently manage your operations process and systems. It ensures the proper functioning of the entire production process and helps to provide quality assurance.

Another case study would help with perspective, right?

Let’s take, for example, how SweetProcess helped Resolute Legal successfully scale up by creating an operational structure for its employees.

Mr. David Brannen, the founder of Resolute Legal, needed badly to scale his business, but the absence of an operational structure hindered him from achieving his goal. Once he discovered SweetProcess, he was able to easily onboard and train new employees, create and implement standard operating procedures for the employees, create a central knowledge base of important information, streamline workflow, and ensure quality control and customer satisfaction.

SweetProcess focuses on ensuring that every single process within an organization, from creation to execution, is performed easily and efficiently, to yield the desired results. Do not just take my word for it. You can try it out yourself for free.

SweetProcess offers a 14-day free trial and you do not have to input your credit card details to access this free trial. You can walk away if you are not satisfied with the results.

To enjoy all the benefits SweetProcess can bring to your organization, click here now.

CONCLUSION

You can achieve competitive advantage over your competitors.

With everything shared in this article, you can not only decrease costs while simultaneously increasing the value of your product or service, but you can also differentiate your brand from every other brand in your industry.

Conduct your own value chain analysis. Adapt the basic value chain model to fit your organization’s peculiarities, properly manage the activities, and in the end, you will experience increased profits and improved efficiency.

To make things easier for you, we have created a downloadable checklist of the value chain analysis steps. This way, you can have it handy with you during the entire process and tick off completed steps.

To get your copy of the downloadable checklist, click on the button below.