Last Updated on May 1, 2025 by Owen McGab Enaohwo

Without quality control, businesses cannot scale or create a consistent customer experience and product quality. Business innovations have become innumerable, and consumers are accustomed to the speedy delivery of high-quality products and services. In fact, without quality control, a business can have no chance at a competitive advantage.

This article will cover what quality control is, why it’s important, quality control methods you can use, and how you can use SweetProcess to implement some of those methods in your business.

By the way, if you want to supercharge your business processes today, take our software for a test drive. It’s free, fast, and you don’t need your credit card.

What You’ll Learn In This Guide

Why Is Quality Control Important?

Steps in the Quality Control Process

7 Quality Control Methods You Can Use in Your Business

How to Implement Quality Control With SweetProcess

How SweetProcess Helped Simple Solutions Make Their Processes Lean

Quality Control vs. Quality Assurance: How Are They Different?

What Quality Control Looks Like in Different Businesses

4 Applications of Quality Control You Can Learn From

Supercharge Quality Control With SweetProcess

What Is Quality Control?

Quality control (QC) comprises the measurement and analysis processes used to determine a product’s quality against a standard set internally by a quality management department or externally by regulatory bodies or industry standards. This proactive approach helps a business inspect, identify, and remove product defects (or prevent service hiccups) before reaching its customers.

In this context, quality refers to a product or service’s features and distinct characteristics. Control, on the other hand, refers to limits in the variance of features and performance.

During production, quality control aims to catch deviations from set quality standards. Although the QC process is traditional (think manufacturing), small or service-based businesses can use QC effectively, too.

For instance, if an agency wants to maintain a consistent customer service experience, the team manager needs to create a process guide to show team members how to resolve queries. The guide will ensure everyone from greenhorns to veterans is on the same page.

The result of this?

Every customer gets taken through (roughly) the same process when interacting with the business. This creates trust and loyalty.

Why Is Quality Control Important?

Companies with quality control processes consistently make reliable products. This is crucial to customer satisfaction, customer retention, and business growth.

Consistent quality can improve your brand’s reputation and put you leagues ahead of your competitors. Aside from customer satisfaction, here are other ways QC can benefit your business.

Lower Cost of Production

When defective products are produced consistently, correcting the defects will require more labor hours and raw materials.

This shifts production timelines further into the future.

However, implementing quality control at every production stage reduces the chances of delays, as errors are quickly detected and rectified. Production becomes more economical this way.

In some business models like fashion and e-commerce, QC helps to prevent the hassle of returns and the associated costs.

Defect Prevention

QC locates defects in raw materials and processes that could cause problems at the final production stage.

This way, defects are prevented before they even occur.

Compliance and Regulation

Most geographical regions regulate production. Quality control will help a business meet those standards. Sometimes, processes need to be compliant. Meeting set standards will help businesses avoid lawsuits and fines from industry and government regulatory bodies.

Compliance is also a competitive advantage. Swiss watches, for instance, have many certifications. However, the COSC (Contrôle Officiel Suisse des Chronomètres) certification is one of the most rigorous, and thus, a big selling point for watches that carry it.

It tells the user, “I am reliable, and COSC has made sure of that.”

Brand Reputation

A brand reputation is built based on how a company interacts and conducts itself before its customers, competitors, and employees. Essentially, everyone is looking at what your company is doing. Internally, that’s what contributes to company culture.

A customer’s perception of a business is tied to their experience with service and product quality. If the product quality or customer experience is inconsistent, they lose faith in the brand.

Quality control is how a business maintains consistency across all channels. Consistency leads to trust, which leads to significant brand equity that becomes valuable over time.

Increased Customer Satisfaction

Intentionally or not, you set customer expectations with every product you create. And consumers typically note errors and defects more easily than improvements.

To keep customers happy, you only need to produce and maintain a quality product. Quality control ensures that you meet those expectations every time.

The last thing any Coca-Cola customer would want is to grab a cold Coke on a hot day and taste some lemony tanginess. That would be jarring and possibly traumatizing.

Increased Customer Retention and Loyalty

The direct consequence of customer satisfaction is that you retain a large portion of your customer base because they are loyal.

Having a handful of customers with a high LTV (lifetime value) is more valuable than a torrent of customers from quick sales or trendy marketing tactics.

Boost Sales

We’ve already stated that quality control helps a business be more consistent in output. One of the understated benefits of this consistency is free word-of-mouth advertising.

Mark Rippetoe, for instance, has been running his gym in Texas for a few decades, and he credits a chunk of his success to referrals. Guess what? His training system is standardized and repeatable, so much so that he has 27 gyms in other states at the time of writing, with plans to open seven more. Talk about the power of consistency.

Boost Employee Morale

More often than not, employees are invested in the success of their work. Quality control benchmarks can help keep employees motivated and more invested in being productive.

Because your standards are clear, they can see their actions move all the needles that matter. For motivated employees, this can be all they need to show up for overtime.

Increased Quality Consciousness

A culture of excellence is not accidental. And quality standards help to reinforce the culture of excellence. Things like processes, especially policies, help keep the work rate at a high level and standard.

Fostering a quality consciousness is even more useful than micromanaging because everyone has a sense of the kind of work expected of them.

Improve Production Methods

Being deliberate about quality control means taking measurements. And what can be measured can be improved.

If you can disassemble and dissect your production processes, you can easily spot and fix bottlenecks. Quality control activities do create a compounding effect.

More Effective, Efficient Use of Resources

The compounding effect continues.

When organizations implement lean process improvement, they optimize resource allocation, ensuring that materials, time, and labor are used more effectively.

By reducing defects and minimizing returns, businesses prevent unnecessary waste and create a more sustainable production system.

Steps in the Quality Control Process

Implementing quality control is an analytical venture that requires you to examine which aspects of your product or service you want to improve and then set the controls (standards) for those parameters.

You could decide to reduce delivery time or response time. You may also increase the perceived quality of your product or service to raise prices smoothly.

Regardless of whatever aspect you want to improve, the following steps will generally help you achieve them:

- Decide on the quality to improve

- Define controls

- Test

- Optimize

- Document

Decide What to Improve

Although you should aim to improve quality in all aspects of your business, narrowing down to one or two aspects is more profitable than tackling every aspect simultaneously.

To help you choose where to start, browse your company’s mission and vision statements and your quality objectives. A quick glance at these and an honest internal monologue will reveal where you should begin.

Since one of the definitions of quality is “making a product exactly to a customer’s specification or satisfaction,” examine some of the features of your product that don’t quite meet up to your customer’s expectations. If you’re running a service-based business, doing this is as simple as browsing the bulk of complaints you get regularly.

Define Controls

The next step would be to define the standards (or controls) for the selected quality.

This means you will have to establish what you want the final product to look like and how it will perform. In the case of a service, you will have to decide what the deliverables are: consistency, responsiveness, customization, etc.

It must be clear what the controls are because that’s the standard that will be replicated.

Test

After outlining the parameters you want to optimize and defining the standards, the next thing to do is a test run.

The test aims to see whether the process holds up under the pressure of repeated execution.

You can test in many different ways. You can use someone new on your team to carry out a process. Then, make the test even more varied by asking someone on your team who is more experienced to perform the same task.

Do the same task many times until you have a large QC sample of data.

Review and Optimize

Since people rarely get anything right on the first try, you’ll likely find inconsistencies in your testing results. This is a chance to ask why and then determine how to achieve more consistency.

Reviewing your results allows you to improve what is already good to make your controls even better.

Documentation

Once you find something that works, something that you’ve tested and optimized, it’s time to etch it in stone.

Compile everything you’ve discovered into easy-to-read documentation and store it somewhere it can easily be accessed and shared.

SweetProcess is an easy way to document all your organizational assets. You can store your processes, procedures, and policies all in one place. Even better, you can store all of them inside a knowledge base that your team can use.

You can even make the knowledge base public (customer-facing) so your customers can help themselves.

Later, we’ll discuss more ways to use SweetProcess to implement quality control in your business.

7 Quality Control Methods You Can Use in Your Business

There is a myriad of quality control techniques. But in this section, we’ll consider the most usable ones so you can hit the ground running with quality control implementation.

You may not have heard of some of the mentions on this list, but you’ll find them useful. When you’re done browsing this list, you’ll have an idea of which one(s) best fits your use case(s).

Benchmarking

Benchmarking means what you think it does: comparing performance metrics against another external standard. These metrics can be tangible, as in the case of a product’s dimensions, or not. Some good examples are a service’s perceived quality or customer satisfaction.

Comparison may be the thief of joy, but in a business context, especially a quality-centric one, it may be prudent to compare one’s performance against existing standards and quality metrics.

Benchmarks are usually set by the top performers in the industry.

If you can identify performance gaps, it becomes obvious what is necessary to align performance and close the gap.

Pareto Charts

You’ve probably heard about the Pareto principle. This quality tool is simply an application of the concept. If you’ve not heard of the Pareto principle, here’s the simplest definition: 80% of the results come from 20% of efforts.

For instance, 20% of the company’s product line may be responsible for 80% of its revenue. Inversely, the bulk of the bottlenecks in service delivery may come from a much smaller bunch of actions.

Having a way to visualize the most important levers of profit and the most important causes of pitfalls in the production process will go a long way into conserving human resources which would have been otherwise wasted on looking for foxholes.

Problems defined are problems solved.

Taguchi Method

The Taguchi method is named after Japanese engineer Genichi Taguchi who pioneered a preemptive strategy to minimize defects and variations in the end product.

He believed that preemptive quality control measures during the research, design, and development of processes were critical to creating uniformity in product quality and performance.

Although the method itself is overly complicated and can typically only be applied in the context of manufacturing, his framework can be applied to modern businesses.

If a content manager was building out a team of writers, it would be best to choose a central software that the whole team can communicate with, not two or three channels that may cause confusion. They could even take it a step further and research the software to make sure it was user-friendly.

What if the team consisted of members across different time zones? A way to eliminate variation would be to choose a fixed time zone to assign deadlines and meetings.

Let’s expand on the example even further. To ensure that the writers all created content that didn’t require too many edits, it would be best to provide style guides and briefs that detail the goals of the content.

In short, preemptively control the outcomes of your team by streamlining and optimizing all your processes and tools.

Lessons Learned Log

The lessons learned log is a tool that details conclusions from a task’s performance or the process’s completion.

These lessons are then used as reference material for executing future tasks. Like the Taguchi method, it tackles mistakes before they even happen.

Checklists

Checklists are a way for anyone to audit processes and verify that every necessary step has been completed.

Checklists also allow for team-wide autonomy. They are a standard that tells your team exactly what you require of them. If external auditors, like a government agency, had a quality requirements checklist, internal processes could easily model that. Compliance is thus inevitable.

Fishbone Diagrams

Invented by Kaoru Ishikawa, fishbone diagrams, or the Ishikawa diagrams, are tools used to find the root causes of problems.

The problem to be solved is analyzed along the following lines: methods, machines (equipment), people (manpower), materials, measurement, and environment. These are just broad terms, but they can be more specific.

If, for instance, a deadline is regularly missed, this diagram allows for team leaders to find out why. Is it because the processes to execute the task for the client are unclear? Or is there a hitch in communications?

Discovering why the end product (or service) isn’t up to par helps to prevent future occurrences.

Processes

Processes are an easy quality tool to use. They consist of steps arranged in order, detailing exactly how a task should be performed.

When tasks are done with processes, the outcomes are consistent, and there’s little to no variation in the end product or service delivery.

Processes help businesses scale. They can also make it easier for new team members to become productive and efficient quickly. Processes also serve as a checklist because employees can review process documentation against the steps they executed to self-audit.

Next, we’ll explore how SweetProcess can help you create processes easily.

How to Implement Quality Control With SweetProcess

Creating processes is the most basic way to implement quality control in your business. Processes allow you to clearly outline the steps to complete a task in a scalable way. You can create a process once and then be done with it.

With SweetProcess, you can create detailed processes containing images or screenshots that let your team members know exactly what is required of them.

You never have to revisit your processes except to update or refresh them. With processes, you establish a standard for work and keep it there. Everyone who performs that role performs it according to that standard.

Here’s a step-by-step guide on using SweetProcess to implement the quality control system in your business.

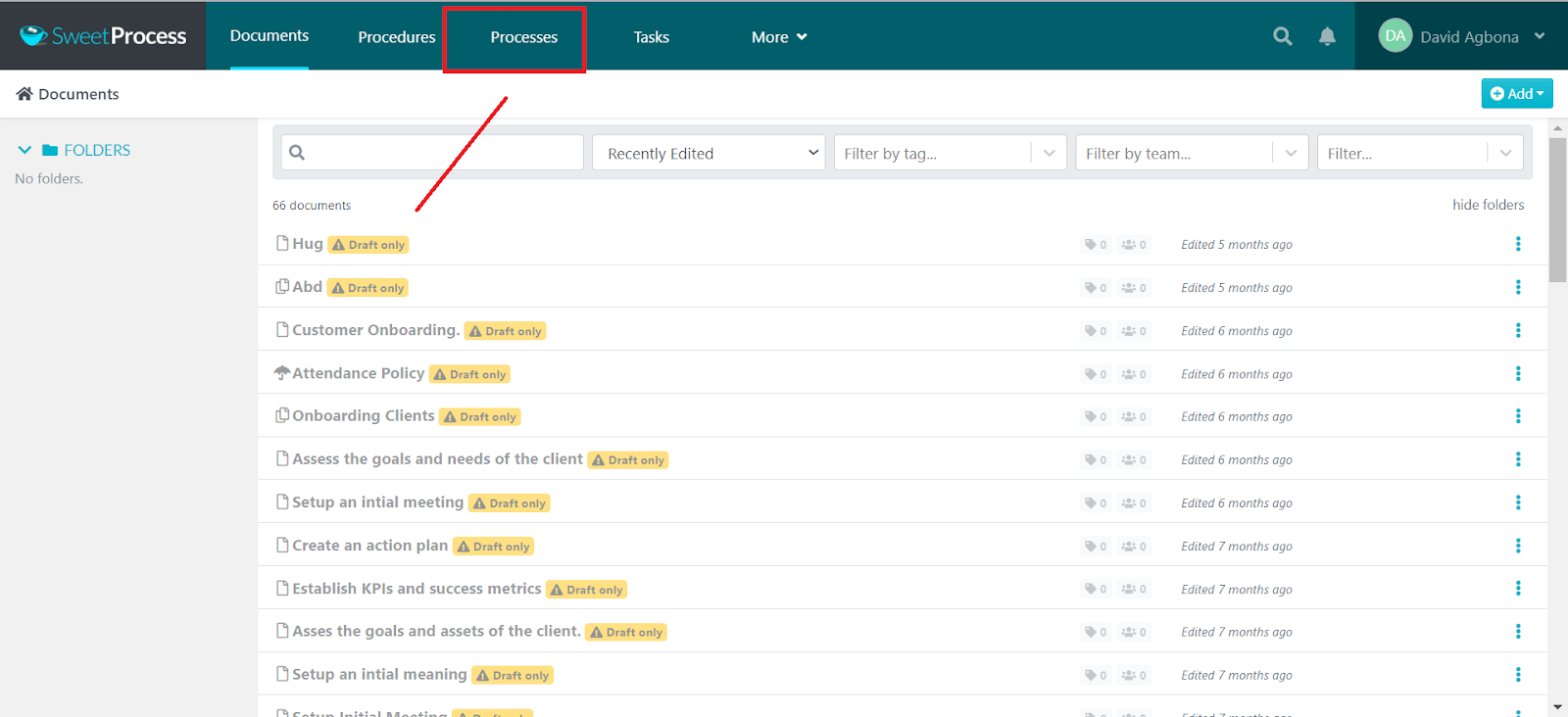

How to Create Processes with SweetProcess

For this demonstration, let’s examine how you can create a process for customer complaint resolution.

Step 1

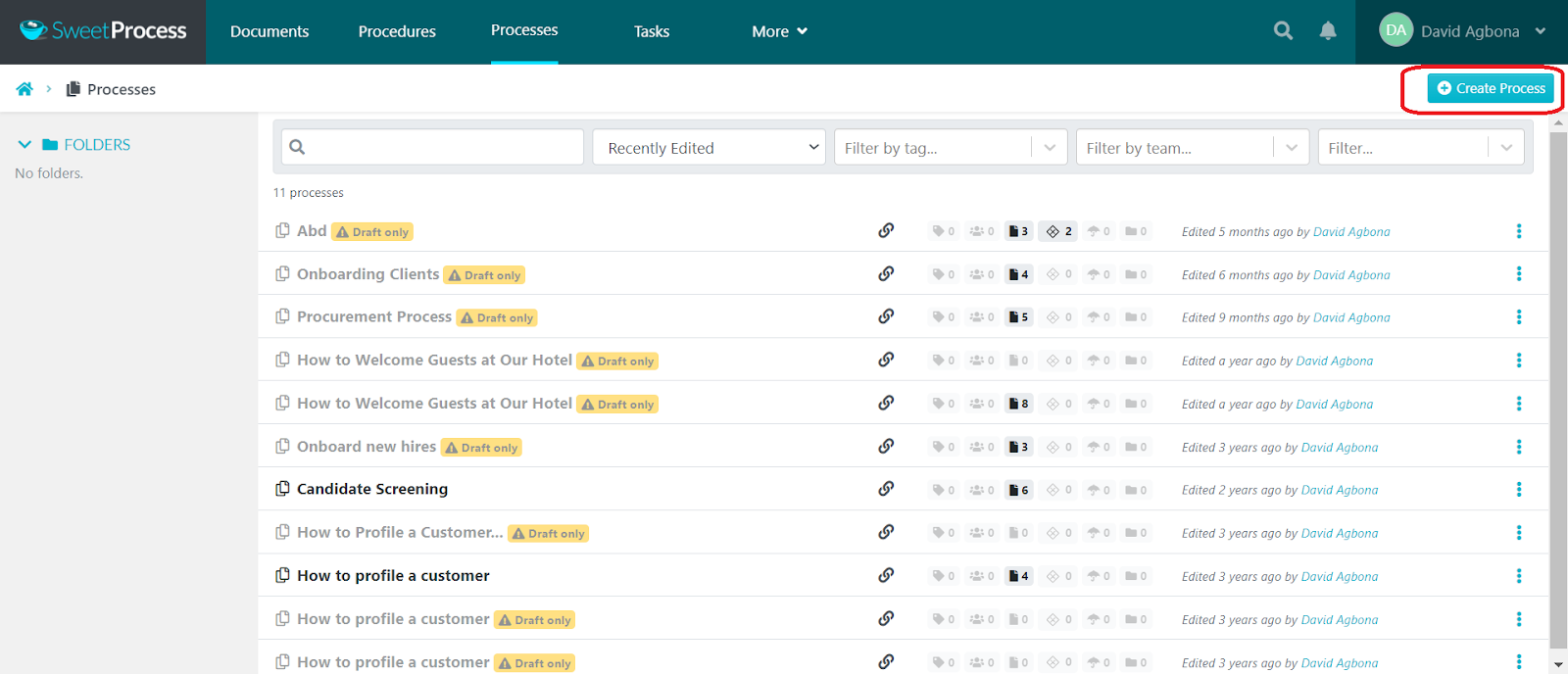

Load SweetProcess and navigate to the “Processes” tab in the top taskbar.

Step 2

Once in the processes bar, click on “Create Process.”

Step 3

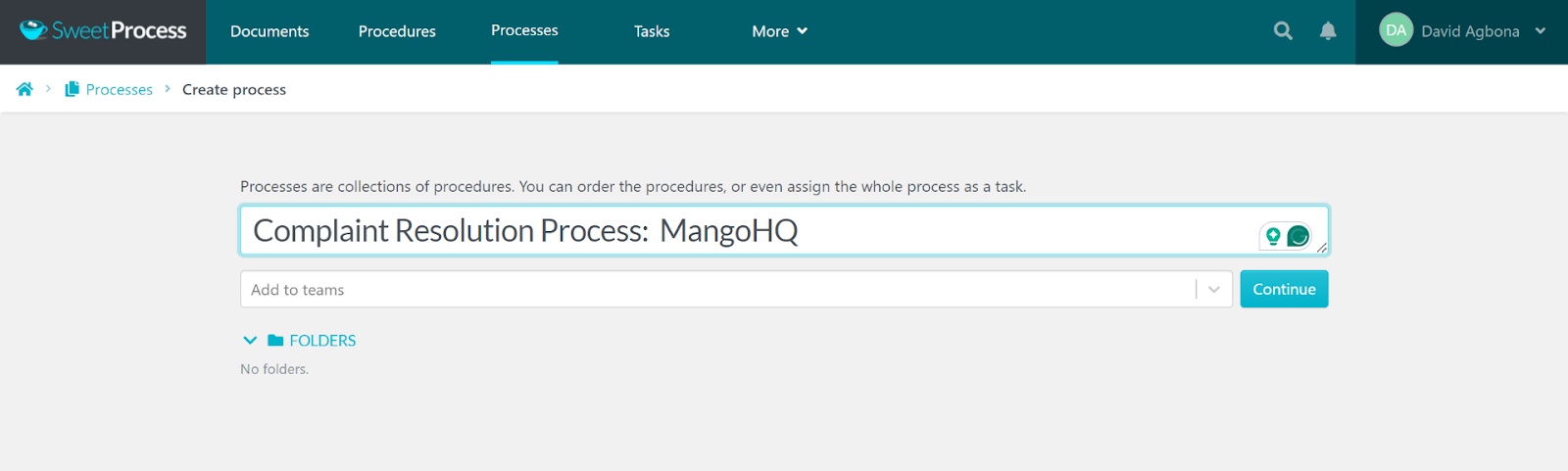

You’ll be presented with a dialog box when you click create process.

In the empty field, type the name of the process. It is important to name the process so you can stay organized.

Complete this step by typing “Continue.”

Step 4

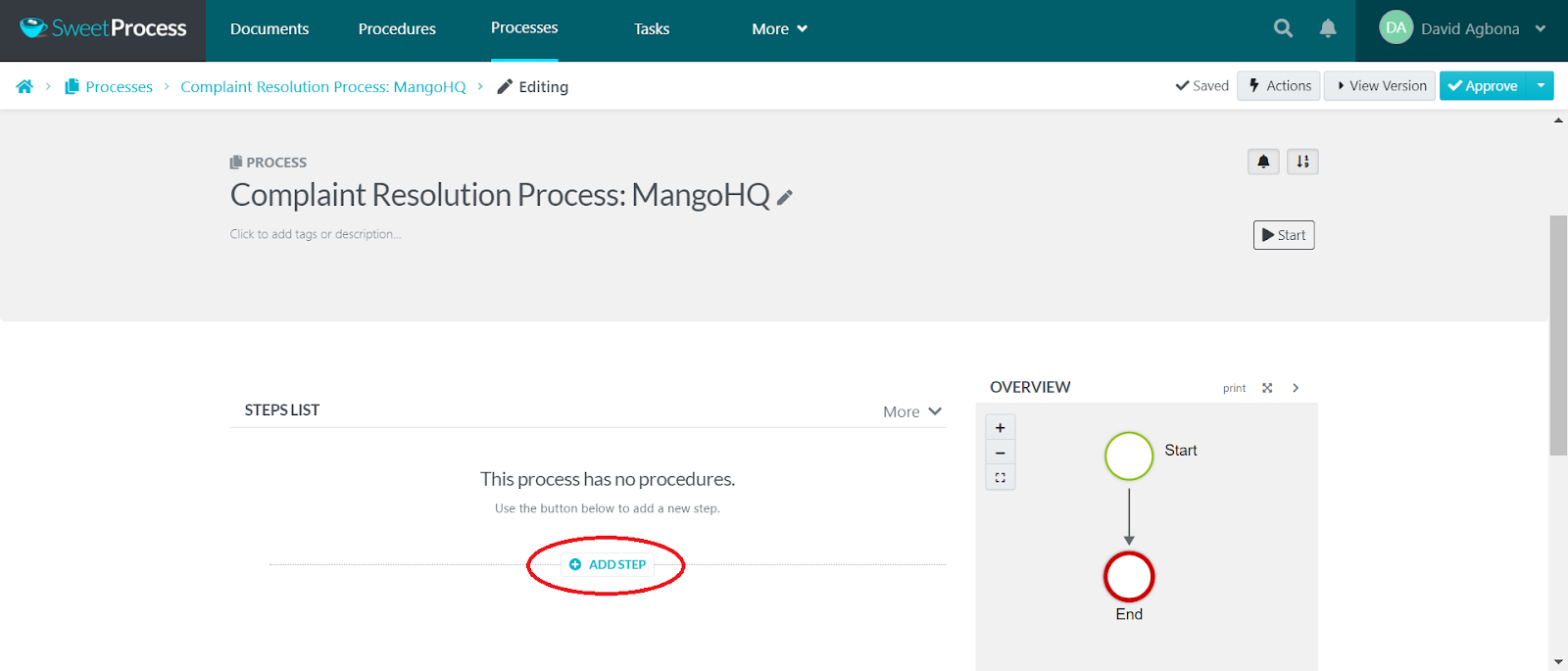

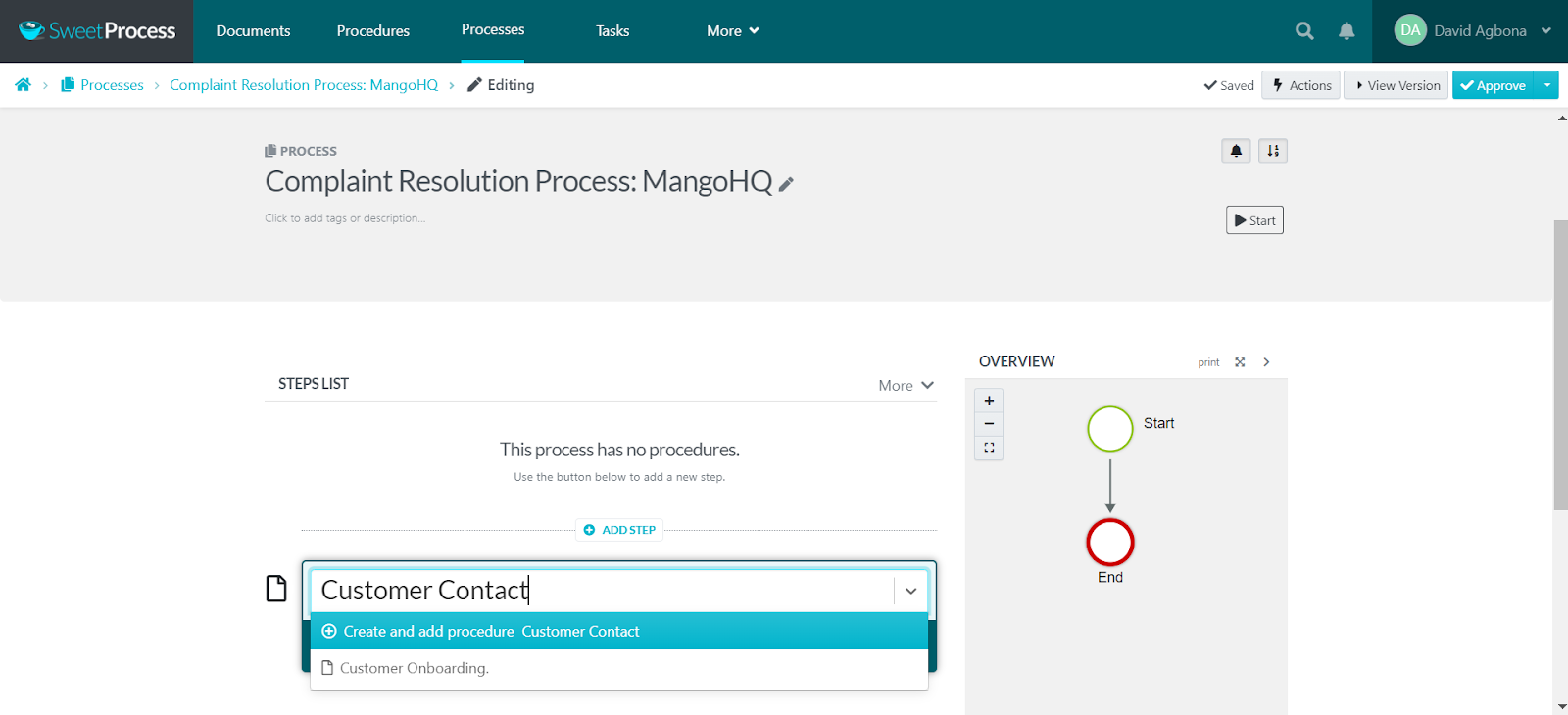

After titling your process, add the steps that make up the process.

You do this by clicking “Add Step.”

Step 5

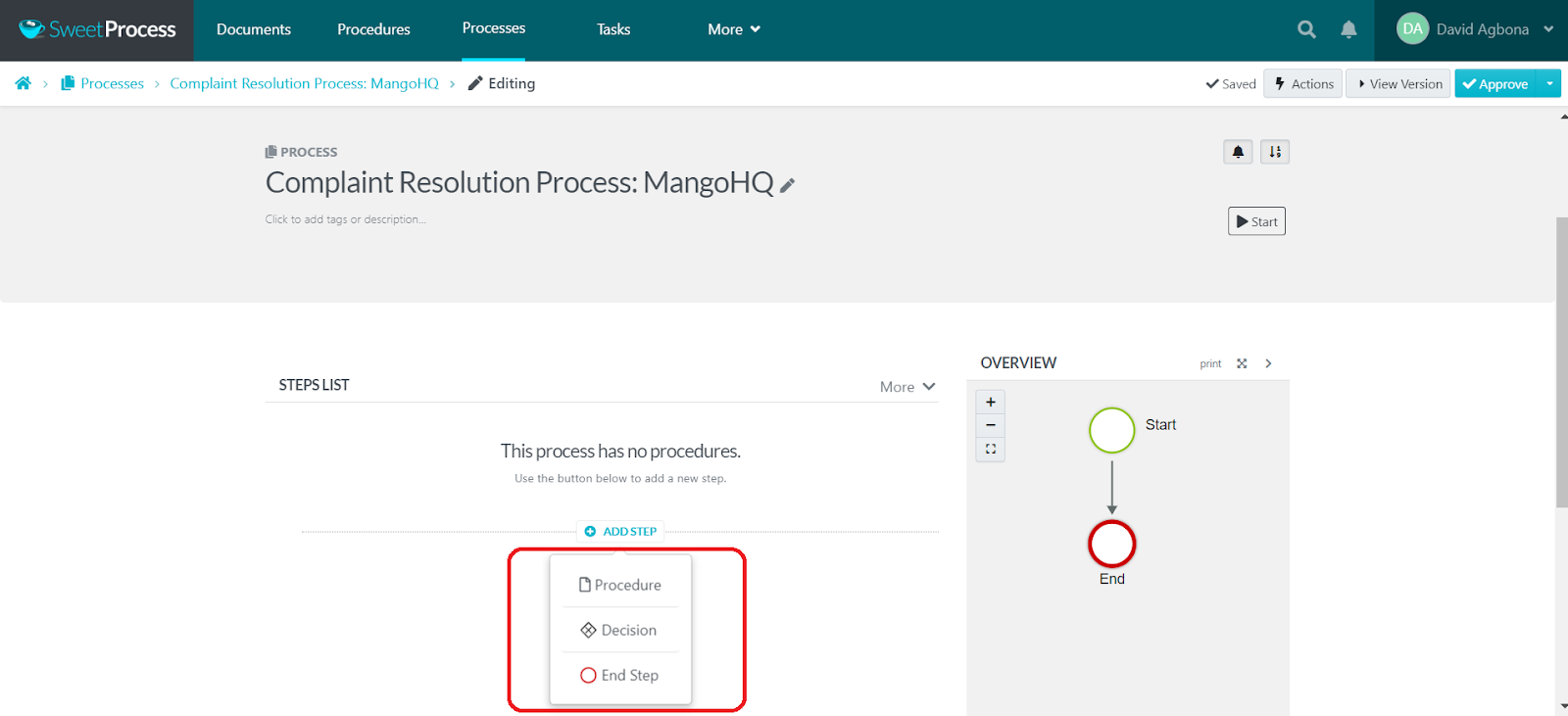

In the presented dropdown menu, click “Procedures” to add all the necessary steps.

Step 6

When you click “Add Step,” a dialog box appears, and it allows you to label the step appropriately.

Step 7

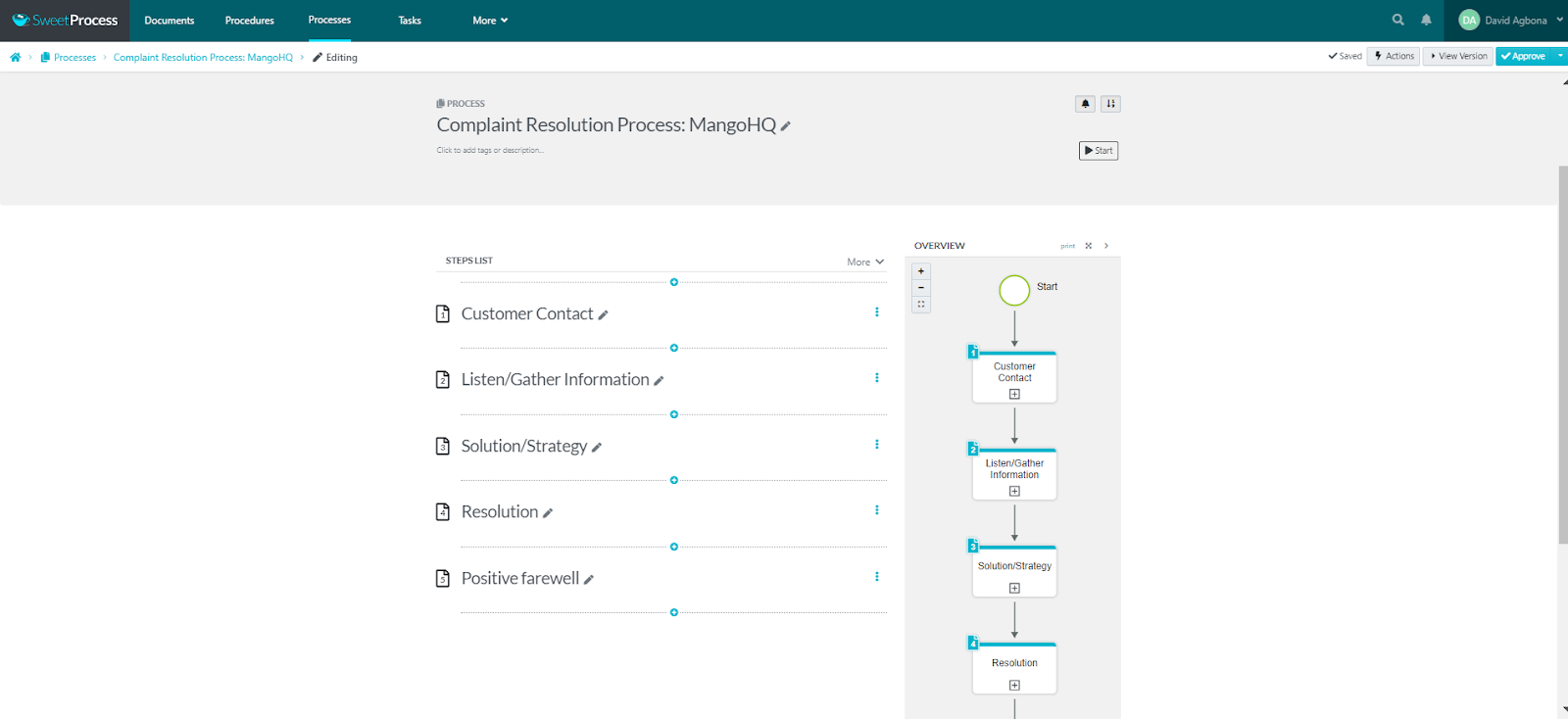

Do the same for the remaining steps.

Step 8

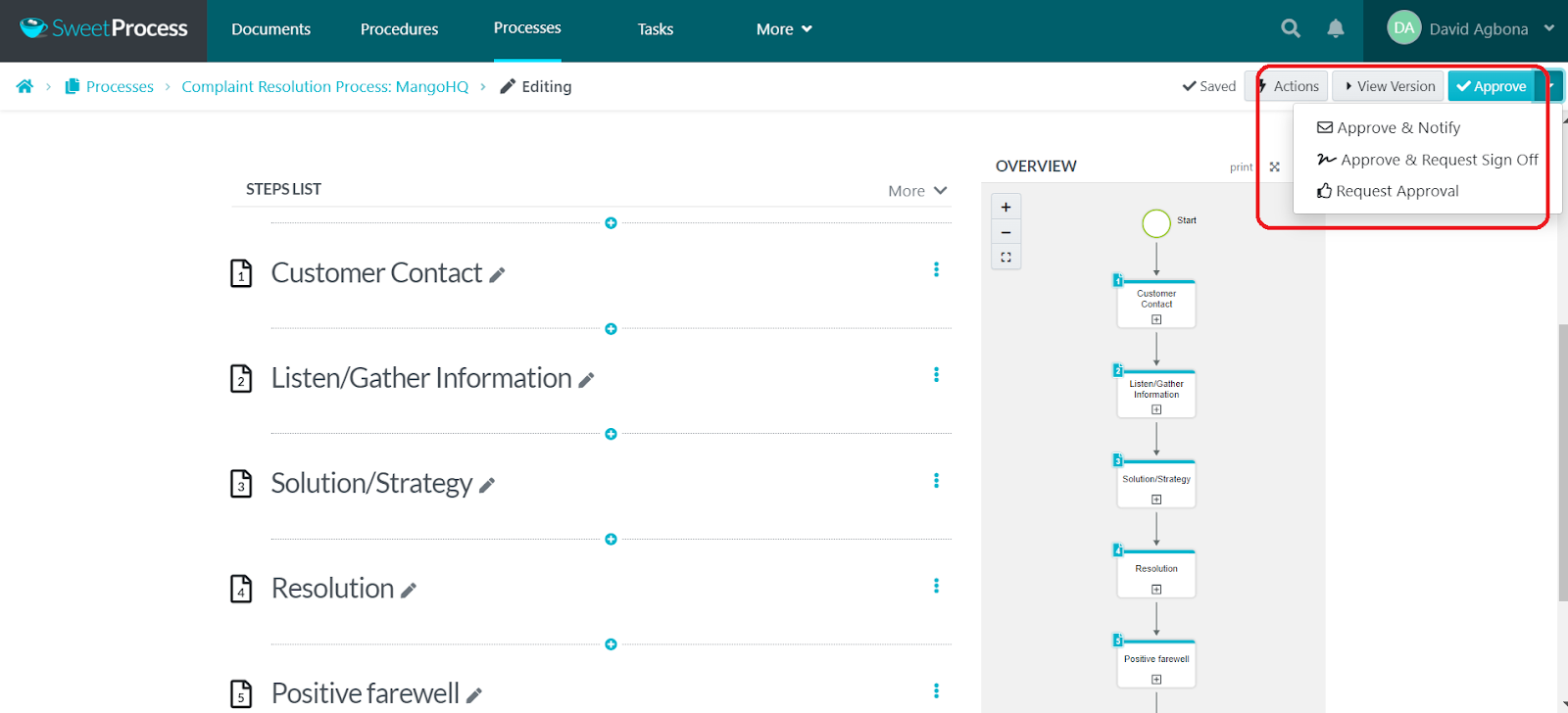

Finally, processes remain drafts until they are approved. If they are not approved, they cannot be shared, viewed, or assigned as tasks, effectively making them useless.

There are three ways you can approve processes and take them live. You can either “Approve and Notify,” “Approve & Request Sign Off,” or “Request Approval.”

The option you choose depends on your position in the team.

Policies With SweetProcess: The Next Step of Quality Control

Creating policies is the next step above processes. This section briefly explores how you can use SweetProcess to create policies your team can easily access and reference.

Step 1

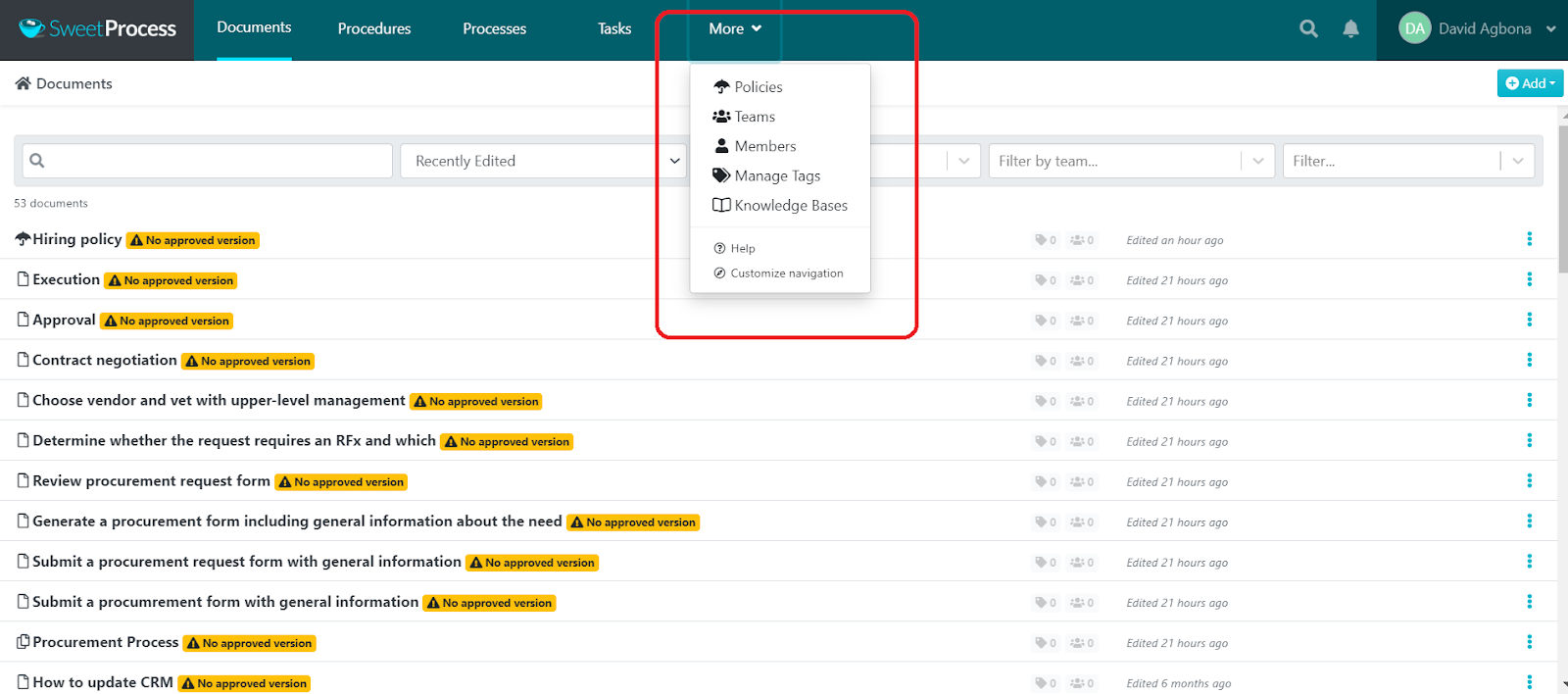

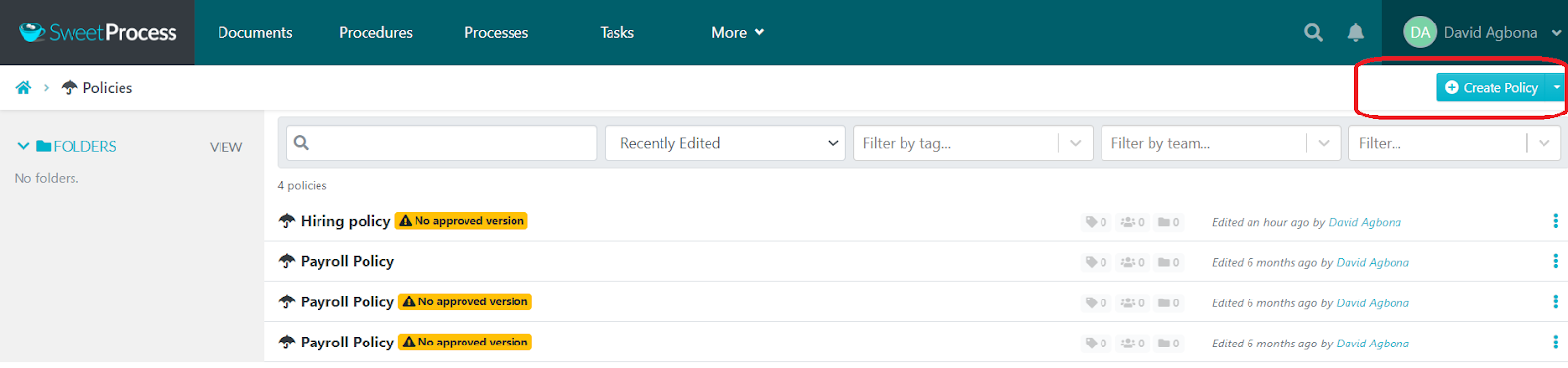

Just like with processes, load the SweetProcess dashboard. Once there, locate the “More” tab and click on it.

In the dropdown menu, select “Policies.”

Step 2

Once you select “Policy,” a new page loads containing all the policies you’ve already created or drafted.

To create a new policy, navigate to the top right corner of the screen and click “Create Policy.”

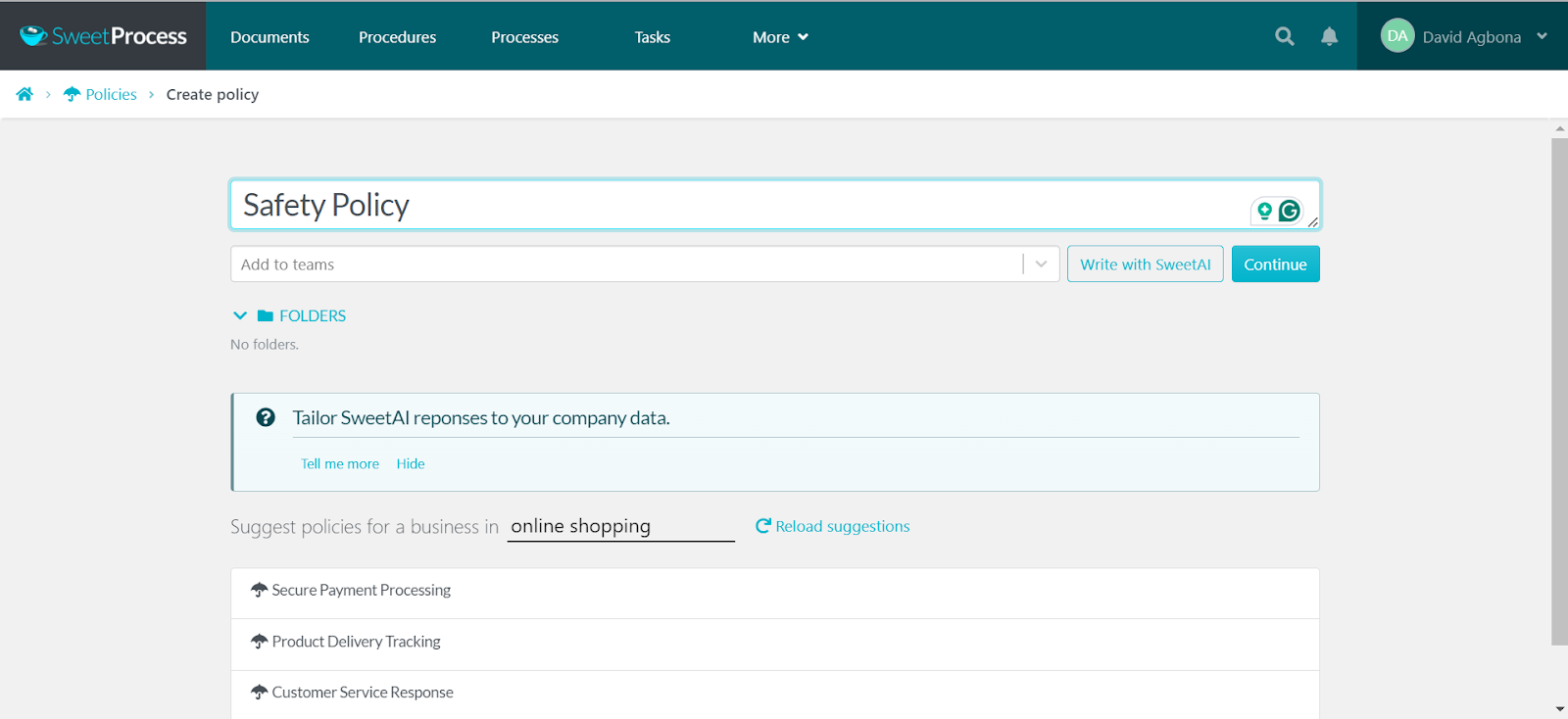

Step 3

The dialog box that appears will let you title your policy appropriately.

Even better, this title doubles as a writing prompt for SweetAI, our proprietary AI assistant that can help you create policies faster, policies you can later edit to your taste.

But in this case, we’ll just go with the option to create the policy yourself. To do this, just click “Continue.”

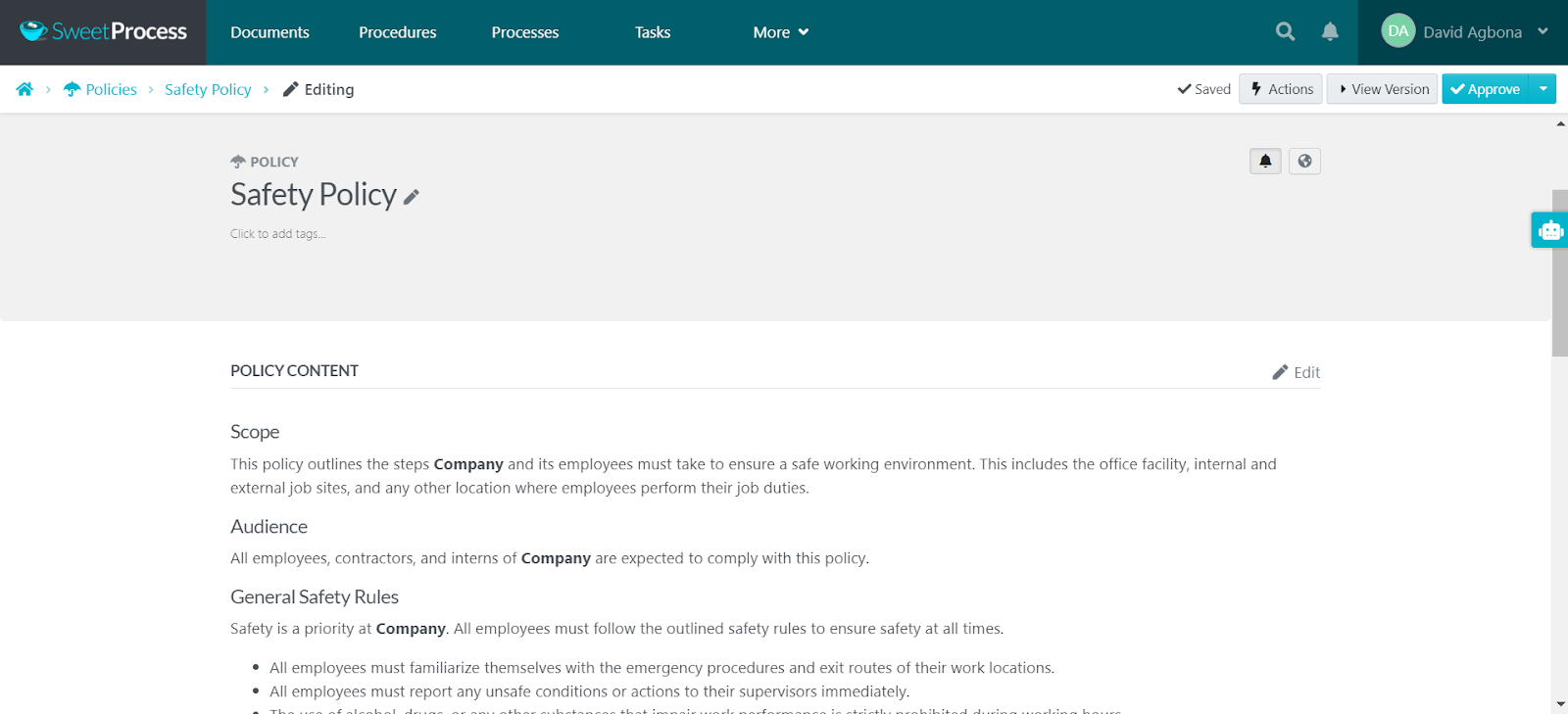

Step 4

From here, all that’s left to do is to write the policy and format it accordingly. You can copy and paste the policy from a Google Doc and or Word file, and then edit and format it accordingly.

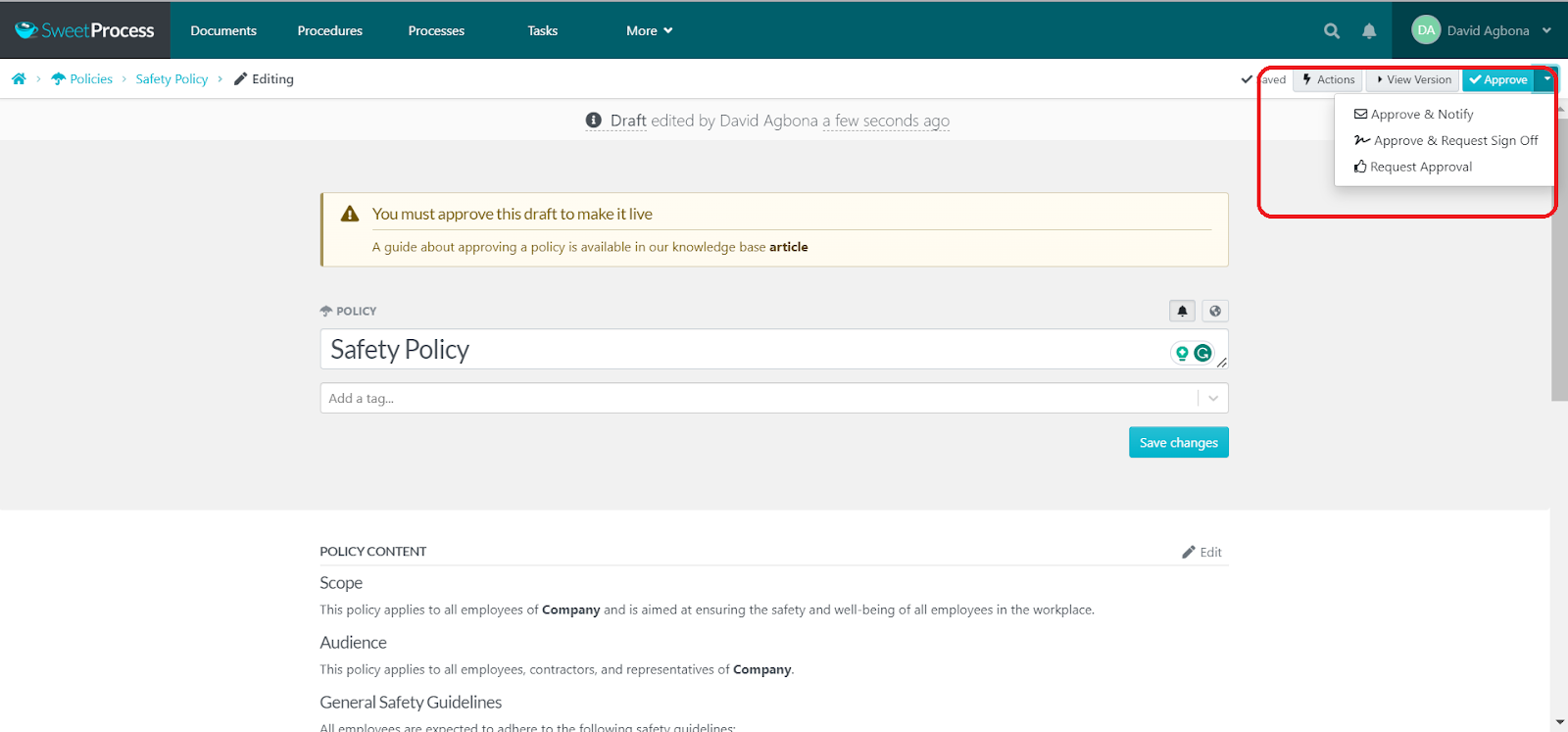

Step 5

As with processes, you have to approve the policy you just created so you and your team can use and share it.

The approval process is similar. You can either “Approve and Notify,” “Approve & Request Sign Off,” or “Request Approval.”

Once you do that, the policy will be live and you can use it as you like.

Types of Quality Control

Quality control methodologies are frameworks with which quality control is executed. You could think of them as strategies that can be implemented team-wide or company-wide to improve quality across the board.

There are many frameworks with which quality can be implemented, but we’ll explore three of the most popular ones, especially because they are distinct strategies that don’t have a lot of overlap.

Lean

The simplest way to define lean is to describe it as minimalist manufacturing or optimized operations. Lean is a management framework that aims to minimize wastefulness to as little as possible while simultaneously optimizing for the most important thing to the customer.

Lean prioritizes economy and efficiency, and there are seven or eight (depending on who you’re asking) parameters to measure waste: defects, overproduction, waiting, non-utilized talent, transportation, inventory, motion, and extra processing.

In a marketing context, this framework could be used to spend as little on ad testing as possible and then leverage ad spending for maximum conversions after finding a winning creative. It could also manifest itself as spending enough for research and development to ensure minimal production costs and maximum profits.

Lean can help you be more profitable. If you can find a way to make your products as cheaply as possible and make it easier and quicker for your customers to get what they need, you’ll satisfy your customers consistently.

TQM (Total Quality Management)

The best way to define total quality management is by creating a company-wide culture of continuous process improvement. Instead of meeting customer needs in the most efficient way possible, the TQM approach aims to unify the efforts of all the departments of a business to reach that same goal.

In this way, every team moves in the same direction and continuously improves their processes. This way, processes become more streamlined.

This may involve all the departments reiterating the company’s mission and vision statement, aligning efforts to create only processes that serve those goals, and choosing to implement those plans in a way that they will always be improving.

Six Sigma

While TQM focuses on a continuous improvement approach to quality, and lean focuses on efficiency, Six Sigma focuses on reducing product defects.

As one of the leading Process Improvement Methodologies, this framework uses statistical methods to detect defects and isolate the cause of these defects.

This method is most relevant to industries like manufacturing and engineering.

How SweetProcess Helped Simple Solutions Make Their Processes Lean

Simple Solutions is a B2B consulting company that serves clients in the manufacturing, retail, and distribution sectors, helping them to improve their production and inventory management.

Like many founders, Alejandro was wearing many hats at the same time. He was not only running admin tasks, he was handling marketing and sales as well. But the performance of his team did not help matters at all. His assistant, for instance, would go to him with the same questions repeatedly. Although he would give her instructions, she would make mistakes and have to redo them.

He got tired and decided to find a solution. He first tried a mishmash of Camtasia, Trello, and Basecamp. But it didn’t work very well. He knew he had to streamline his processes if he was going to scale his business.

He found SweetProcess, and although it was challenging to get all the processes documented, he did so, and his performance immediately improved.

For one, he and his team were able to carry out workshops more effectively than before. Previously, workshops would overwhelm him, and he would lose track of all the tasks he needed to complete, including his attendees, equipment, handouts, pictures, and testimonials. Now? He only has to assign the quality control procedure to his assistant. And workshops move along very smoothly.

Quality Control vs. Quality Assurance: How Are They Different?

Although they both aim to achieve the same goal—improve quality—the differences between quality control and quality assurance boil down to their scope(s).

You can think of quality control as the boots-on-the-ground agent, while quality assurance is the commander who gives all the commands.

Quality assurance is the overarching organizational strategy that keeps a business compliant with internal standards (set by management) and external standards as specified by customers, stakeholders, and the government of the region. Creating a culture of continuous improvement can be classified under QA. Streamlining onboarding is also a QA move.

Quality control, however, is concerned with the quality of specific product or service excellence parameters. A product may need to be made to exact dimensions, or a certain aspect of a service fulfillment may need to be fine-tuned. In essence, QC is concerned with the specifics of quality implementation. An example of quality control may include the creation of processes.

What Quality Control Looks Like in Different Businesses

Does quality control differ from industry to industry? Yes and no. Yes, quality control is applied differently in various industries as each industry’s ecosystem is unique. On the other hand, the same frameworks are applied in different industries.

Manufacturing

Manufacturing is the discipline that birthed many of the quality control methodologies that we have today. And the Asians championed that move. Ishikawa, the Taguchi method, and Kaizen are only a few of their brain babies.

Quality control in manufacturing can be tackled in many ways. Lean can be used to reduce waste, Six Sigma is most useful in using statistical methods to identify waste and the source of the waste, and JIT (just-in-time) can be used to make sure that parts are readily available as soon as they are needed.

Food

Food must be made to high standards. The lives of customers are at risk if quality is neglected.

In food production, the most important things are the food’s nutritional value, its sensory qualities, and how safe it is for consumption. Testing and sampling are usually done frequently to catch mistakes before they even get off the production belt.

Inspection, sampling, and testing are arguably the most critical aspects of food production. Training is also essential for employees; processes and checklists are most relevant to food employees.

Healthcare

Just like food, healthcare is essential to the well-being of customers. With healthcare all the equipment must be working optimally. This means that equipment should be checked regularly, and spare parts should be available when necessary.

Clean environments are important for patients and doctors to be safe. Therefore, processes and policies for maximum cleanliness are important. Checklists also help the cleaning team to avoid violating any safety protocols.

Because healthcare is a process-oriented industry, processes, policies, and checklists are the most useful tools.

JIT (just-in-time) and TQM are also tools that healthcare managers can use to ensure that operations run smoothly.

Fashion

Quality control applies to both fast fashion and bespoke fashion. In the case of fast fashion, training is paramount. Onboarding, training, and safety are the typical management concerns in the fashion industry.

But in the case of bespoke fashion, sourcing is the most important thing. It is important for the procurement team in a bespoke fashion house to streamline their sourcing processes.

In bespoke fashion, quality is enforced from concepts to execution. This is because bespoke fashion customers require more because they pay more.

In the case of fast fashion, the products are typically cheaper and mass-produced. This makes quality demands less stringent but no less relevant.

Construction

Construction is just like manufacturing, but in this case, safety is more important than manufacturing.

In construction, managers must focus on regulatory compliance, building codes, high-quality raw materials, and safety.

Because of the nature of construction, quality has to be implemented from start to finish. The finished product of construction is irreversible.

Oil and Gas

The Erlanger sector is probably the most complicated because there are many moving parts.

Not only are there moving parts, but humans interface with these moving parts.

The oil and gas sector requires training, onboarding, and rigorous inspections. Furthermore, management must streamline their outsourcing processes and ensure they comply with the industry’s ISO standards.

4 Applications of Quality Control You Can Learn From

Now that we’ve observed what quality control looks like by industry, let’s look at what it entails by department or team.

Customer Service

The customer service team is one of the most important as it is the customer-facing element. With customer service, training, onboarding, processes, checklists, and policies help to provide consistent customer interaction.

Accounting

In financial services, attention to detail is most important. Therefore, audits (inspections), along with processes and policies, will help financial professionals keep track of when and where they are going.

Product Development

The most relevant method to product development is probably the Taguchi method.

Another quality control method that comes in handy is benchmarking.

This is because products must meet the industry’s quality standards when made. They need to perform as well as or better than what is currently available in the market.

Human Resources

Human resources is very process-driven. Here, knowledge bases, processes, procedures, and policies are the most important ways to ensure quality.

Lean methodologies can be applied in human resources, especially where the budget for project executions is limited.

Using economies of scale, human resources managers can find ways to get the top talent with the available budget.

Supercharge Quality Control With SweetProcess

If you want to improve customer satisfaction, increasing word of mouth about your product quality control is how you can improve your product/service today.

SweetProcess is the easy way for you to do that. With a versatile suite of tools, you can easily create processes, policies, and knowledge bases to boost the quality of your products and services.

See for yourself. Sign up for a free 14-day trial. You don’t even need to use your credit card.