Last Updated on March 1, 2025 by Owen McGab Enaohwo

How can you set yourself apart from established competitors in your industry? For one company, the answer lies in efficient production. Toyota struggled to establish itself as Ford and General Motors dominated the automobile market. Committed to improving operations by increasing the quality of its vehicles, eliminating waste, and shortening production time, it gave its competitors a run for their money through the Toyota Production System (TPS).

Continuous improvement is as beneficial to small and mid-sized businesses as it is to conglomerates. Implementing the right tools helps smaller companies achieve the same efficiency.

Regardless of their sizes, businesses have recorded tremendous success by implementing continuous improvement with SweetProcess, a workflow management tool. Sign up for a 14-day free trial without a credit card.

What You’ll Learn In This Guide:

What Is Continuous Improvement?

Why Continuous Improvement Matters

Types of Continuous Improvement Processes

How to Implement Continuous Improvement in Your Organization

How to Manage Your Company’s Continuous Improvement Using SweetProcess

7 Continuous Improvement Examples in an Organization

Tools for Continuous Improvement

Continuous Improvement Metrics to Track Your Progress

Enhance Your Continuous Improvement Efforts With SweetProcess

What Is Continuous Improvement?

“Perfection is not attainable, but if we chase perfection, we can catch excellence.” This quote by legendary football coach Vince Lombardi, who led the Green Bay Packers to win five championships in seven years, resonates with the principle of continuous improvement.

Business processes may never be perfect, but continuously improving them brings operational excellence. Continuous improvement is an ongoing commitment to enhance the quality of a service or product, even when it seems to be performing well. The focus is on incremental progress—taking little steps that make a difference.

Organizations tend to become complacent when there are no visible clogs in their operations. Unlike visible problems that can be resolved, hidden ones are more damaging as they go unnoticed for long. It is detrimental for businesses to not operate at full capacity in a highly competitive environment.

For instance, onboarding new clients in 48 hours might be sufficient until you realize a competitor does the same in 24 hours. Sticking to your current turnaround leaves you in a disadvantaged position.

Continuous improvement is most effective as a collective effort involving all team members. Tribal knowledge is one of the biggest challenges of business growth. Operations suffer when only a select few are privy to important work information. Decentralizing knowledge by documenting business policies, procedures, and processes in a business improvement tool like SweetProcess creates a level-playing field for performance. Team members can retrieve any information they need to perform their duties.

Why Continuous Improvement Matters

Fortune 500 companies have a reputation for high performance and revenue. While their success is admirable, their efforts to attain it are often overlooked.

Many of them grew over time through a continuous improvement process and are reaping the benefits today. Some of its benefits include:

Enhances Efficiency

Regularly improving business processes reduces waste, creating a better use of organizational resources. By striving to improve operations, businesses identify redundancies and develop better methods for accomplishing tasks. Employees are better equipped to perform their responsibilities more efficiently.

Drives Innovation and Competitiveness

Employees often depend on their employers to improve the work environment. In the absence of new and better processes, old ones linger even when they are insufficient. Implementing lean process improvement encourages businesses to discover more efficient operational methods, fostering a culture of continuous innovation. This proactive approach not only enhances productivity but also provides a competitive advantage in the marketplace.

Boosts Employee Engagement

Cooperative employees drive continuous improvement. Simplifying the workflow and creating a conducive work environment encourages high employee engagement. Team members develop a stronger sense of belonging when their interests are protected. This positive mindset inspires them to engage more with one another to accomplish company goals.

Improves Customer Satisfaction and Retention

Increased customer satisfaction and retention are part of the goals of business improvement. Organizations must prioritize understanding their customers’ needs and collect feedback on current processes. Addressing any concerns raised increases customer satisfaction and retention.

Customer satisfaction, or dissatisfaction, begins when they first encounter your business. In today’s digital age, this is most likely their first visit to your website or other digital platforms. Providing something as little as a frequently asked questions (FAQs) page to address customer questions creates a sense of satisfaction that could propel them to engage further.

You can use SweetProcess to build an FAQ page in a few minutes. Try it out with a 14-day free trial—no credit card is needed.

Types of Continuous Improvement Processes

Organizations must consider their particular needs during improvement to achieve desired results. Outlining your reasons for improvement and comparing them with the various continuous improvement processes are effective for avoiding a misfit.

Lean Management

Lean management focuses on eliminating waste in operations. You must identify useful elements in the production chain and remove non-useful ones. This is done on the premise that productivity and efficiency increase when every aspect of the operations is value-adding. Also referred to as lean manufacturing, it is most famous for its success with the Toyota Production System. The five steps of lean management are identifying value, value stream mapping, creating flow, establishing pull, and continuing improvement.

Six Sigma

Six Sigma is a data-driven process for maintaining consistency in output, especially with large-scale production. It is most popular in manufacturing, enabling manufacturers to produce high volumes of materials with precision. Founded by Bill Smith, a Motorola employee, Six Sigma is credited with the DMAIC process of defining, measuring, analyzing, improving, and controlling operations for maximum output.

Total Quality Management (TQM)

Total Quality Management (TQM) is the go-to continuous improvement process for customer satisfaction. It consists of two significant areas: identifying and solving customers’ problems. The customer must be a part of the process, especially in providing useful feedback based on their needs.

A McKinsey Customer Report shows that collecting current customer satisfaction data is essential to developing sustainable improvement strategies.

The PDCA Cycle

Plan, Do, Check, Act (PDCA) is about improving the business process through interaction. You can only truly improve processes when you grasp their current state. When you understand why current processes are how they are, you are better positioned to implement a solution and examine its effectiveness.

Your continuous improvement process choice must align with your business needs to be effective. With organizations losing an average of $15 million annually due to poor data management, many are improving their processes with workflow tools for better data management.

Doing that with SweetProcess offers more advantages as its activity tracker collects real-time data in its secure cloud storage system.

How to Implement Continuous Improvement in Your Organization

It is more practical for businesses to implement continuous improvement with a standardized process. This allows for repetitive and long-term success. Here is a sequence for implementing continuous improvement.

Have a Clear Vision

Improvement goals can be ambiguous and have many facets. Outline your vision to clarify it. Articulate what you want to achieve and how it will impact your organization. Identify the result from your current position and align your efforts toward it.

Identify Areas for Improvement

The eagerness to improve operations might make businesses overhaul their entire processes when that may not be necessary. There might be aspects of your operations that are worth retaining. Single out areas in dire need of improvement and put your resources toward them.

Set Measurable Goals

It is difficult to know what works when improvement goals are not measurable. Establishing metrics for monitoring progress helps achieve desirable outcomes. A goal to shorten turnaround can be measured by monitoring execution time. This is more practical than setting out to have the best operations, as you may be unable to determine if your operations are the best.

Gather and Analyze Data

Collecting and analyzing the data of current processes provides insights into existing problems. A closer look at the data could reveal their root causes. Addressing multiple issues at once can be distracting. Prioritize them based on relevance and urgency for better results.

Provide Training and Support

Employees struggle with change in the workplace. Training them on new processes helps them overcome any difficulties they may experience. Leveraging technology for training simplifies learning by making materials readily available. Adopting the right tool for this purpose is key.

With a tool like SweetProcess, you can create training materials in multiple formats, including text, video, and audio, based on preference. Employees can also learn at their own pace, remotely, by accessing the training materials you assign to them.

Welcome Improvement Ideas

Organizational success trumps individual gratification. Rather than focusing on taking all the credit for continuous improvement, business leaders should welcome ideas from all team members. Every idea has the potential to yield positive results. Ideas should only be discarded when they have been explored and proven unhelpful.

Develop and Implement a Solution

The most effective solutions target specific issues in the workflow. Team members have first-hand experience of their roles. Liaise with them on the best ways to implement new processes. Do they find any steps redundant? If so, remove them. Aim to execute tasks as quickly as possible without cutting corners.

Iterate and Learn From Your Mistakes

New processes may not be optimal initially. Monitor operations and identify setbacks. Work on them again with your team. Note any mistakes to avoid recurrence. If you are not making any headway, give it time. New ideas may crop up later.

Measure Improvements

Monitoring improved processes is key to ensuring positive results. The project is a success if it meets or exceeds expectations. Underperformance is a cause for concern and needs to be addressed. Pay attention to the numbers and compare them to what was obtainable before the changes.

How to Manage Your Company’s Continuous Improvement Using SweetProcess

According to a McKinsey report, organizations implementing digital technology in their operations increase productivity by 20 to 25 percent. Continuous improvement is incomplete without software implementation. Doing it any other way leaves you with average operations at best and business failure in most cases. SweetProcess is a workflow management tool for streamlining business procedures, processes, and policies. It helps businesses find the sweet spot in their processes with comprehensive documentation, automating repetitive tasks, and removing redundancies—all of which are essential for continuous improvement.

The president of Thimbleberry Financial, Amy Walls, experienced this firsthand. As a small business trying to scale up, it could not manage the demands of its processes. According to Amy, SweetProcess over-delivered. “I truly didn’t think it would make that big of a difference,” Amy says about SweetProcess’s impact on its processes. She and her team continue to improve their operations by working with standard operating procedures in the system. “By having SweetProcess, all of our team members can fix whatever is broken that they touch, and they don’t have to come to me,” she added.

Document Repetitive Tasks in One Place

One of SweetProcess’s unique selling propositions (USP) is its effective documentation. First, several documentation templates are available, saving you time when creating one from scratch. Each task can be captured step-by-step for easy implementation.

“It has made it so that my time is not needed to explain the same things to every team member,” Amy says about documenting her organization’s processes in SweetProcess. It gets even better as you can generate documents either manually or automatically using SweetAI.

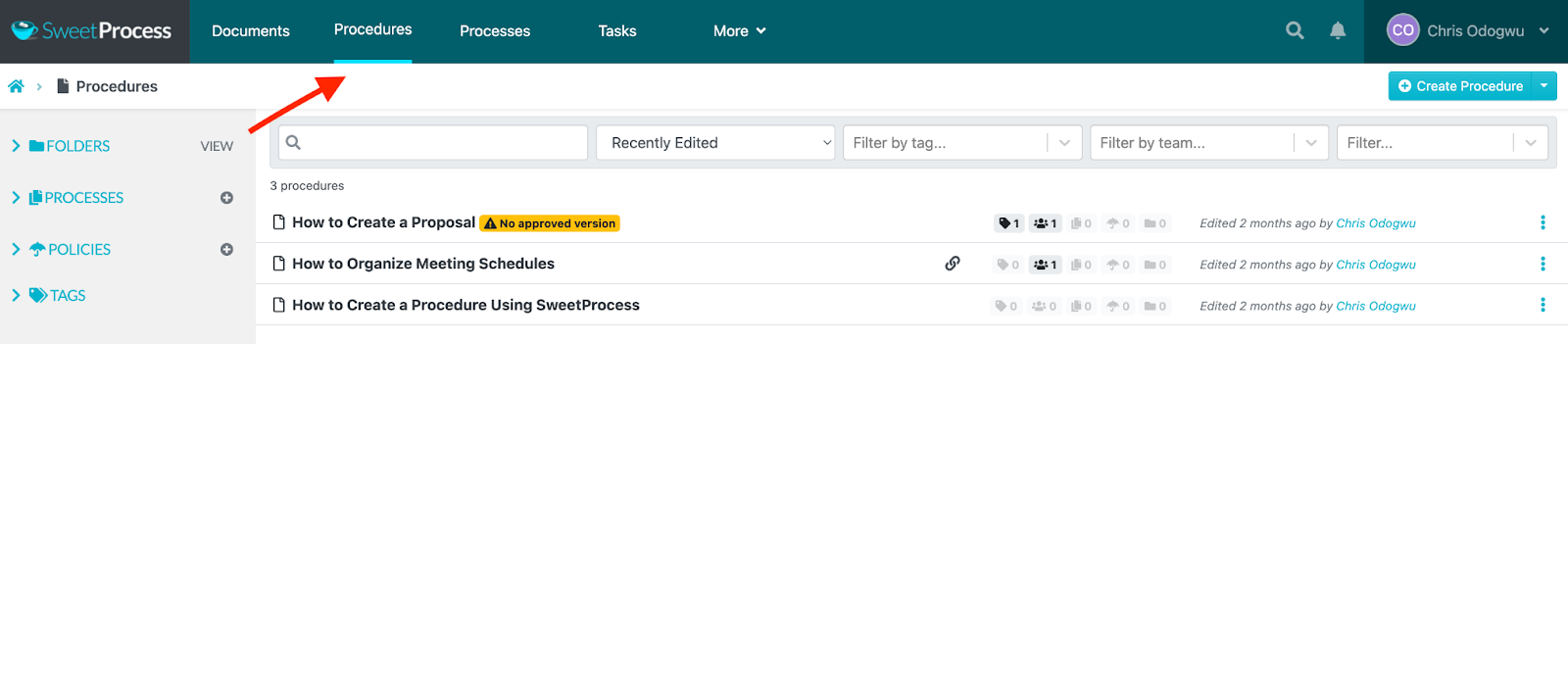

How to Document a Procedure Manually in SweetProcess

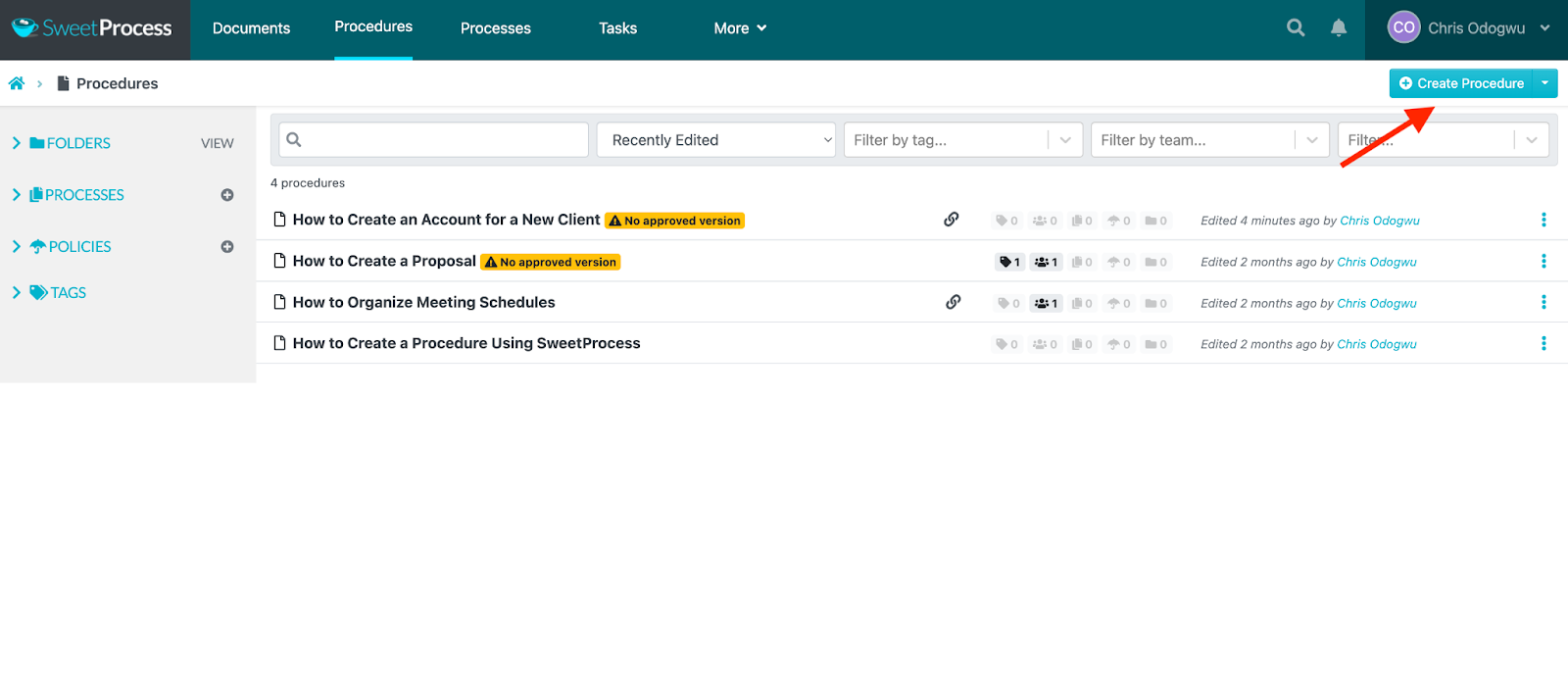

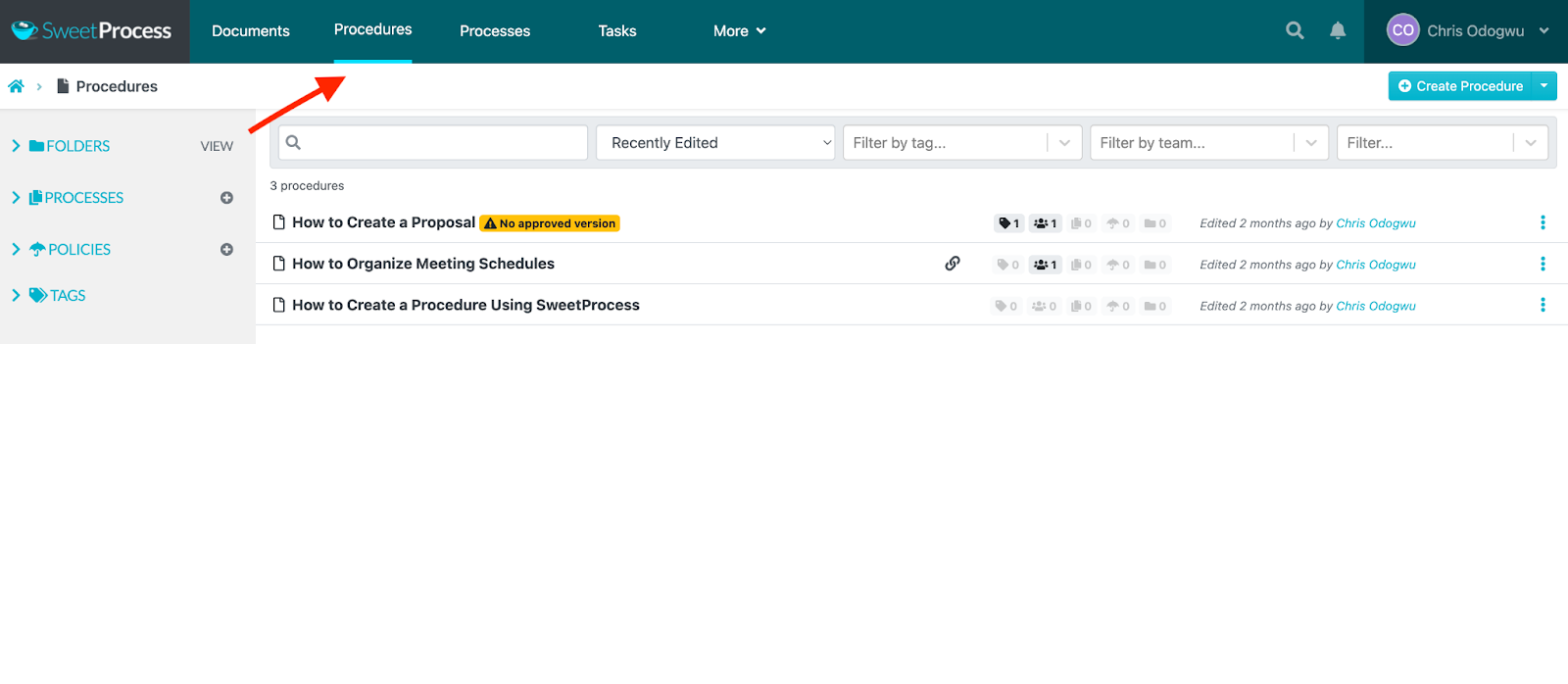

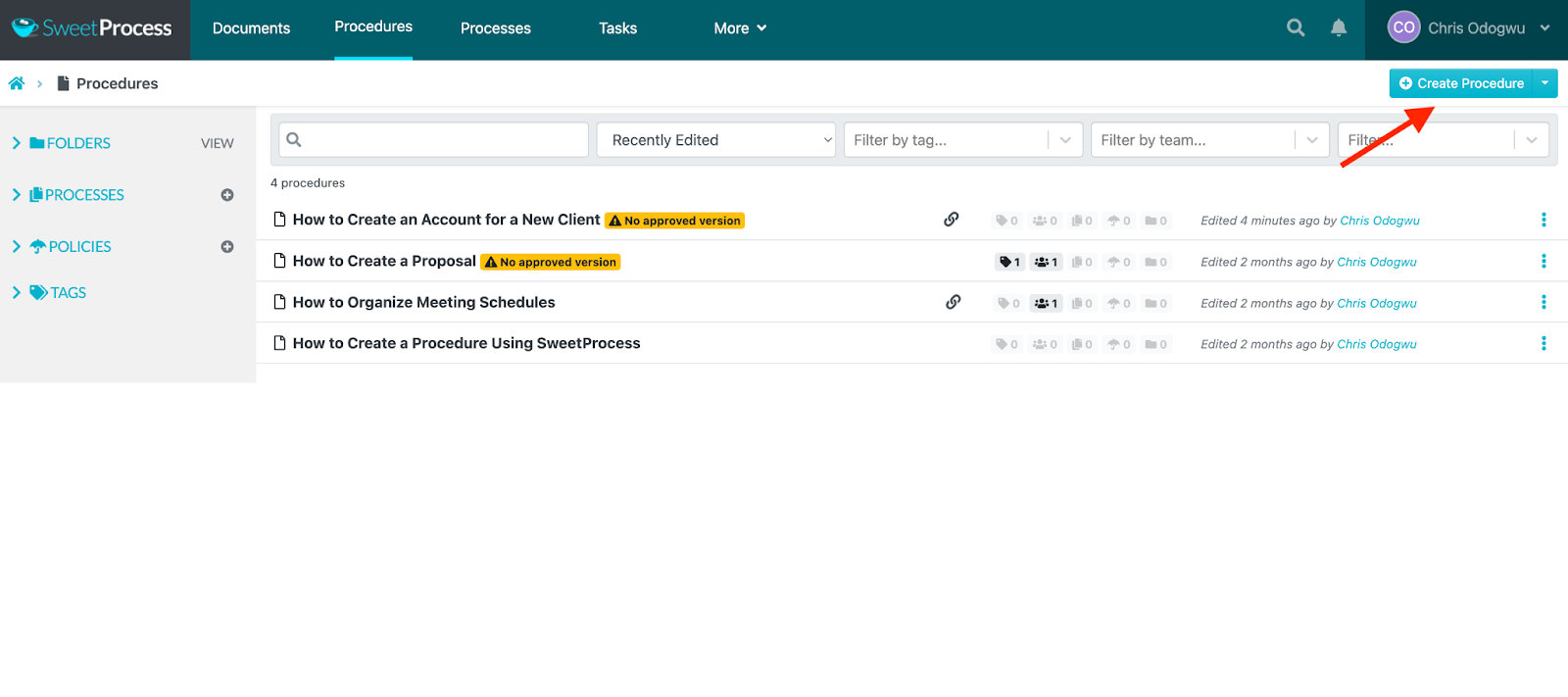

Click “Procedures” and “Create Procedure.”

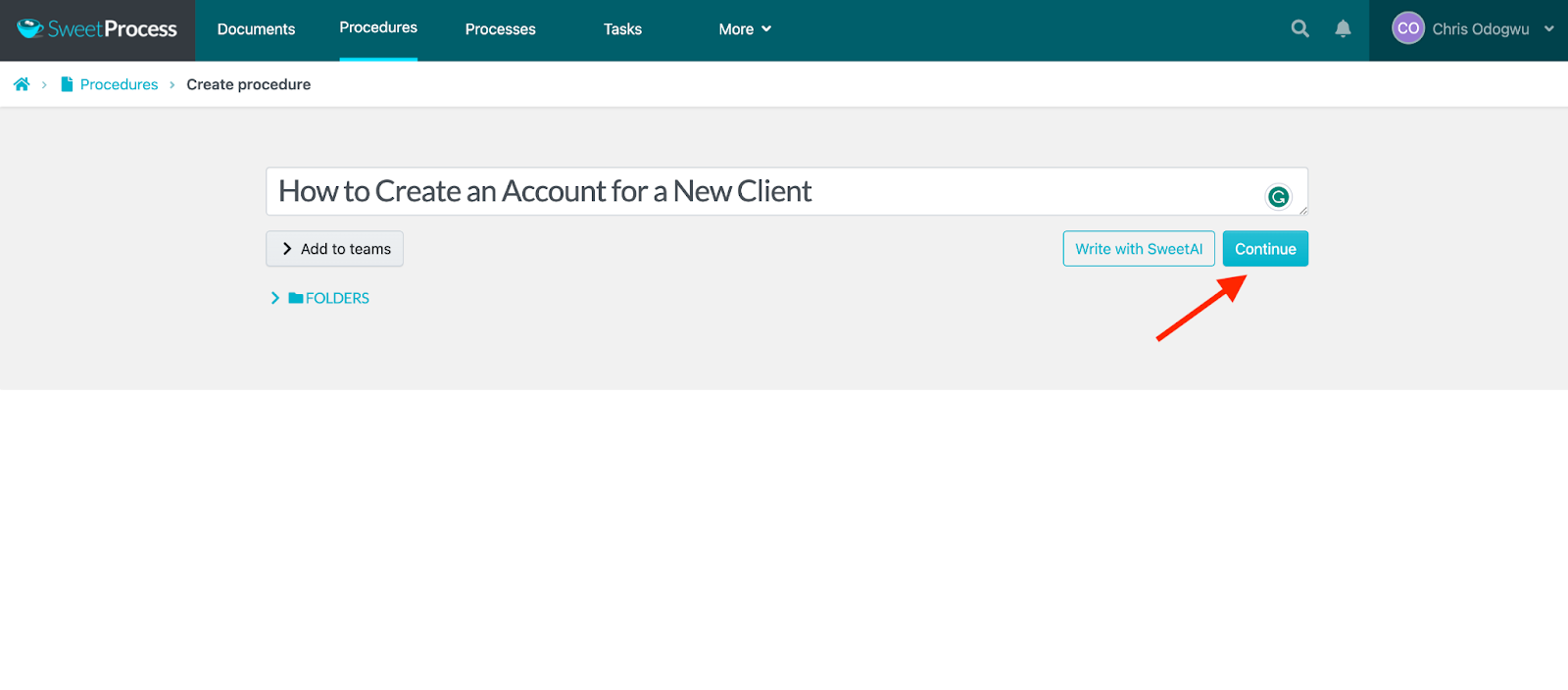

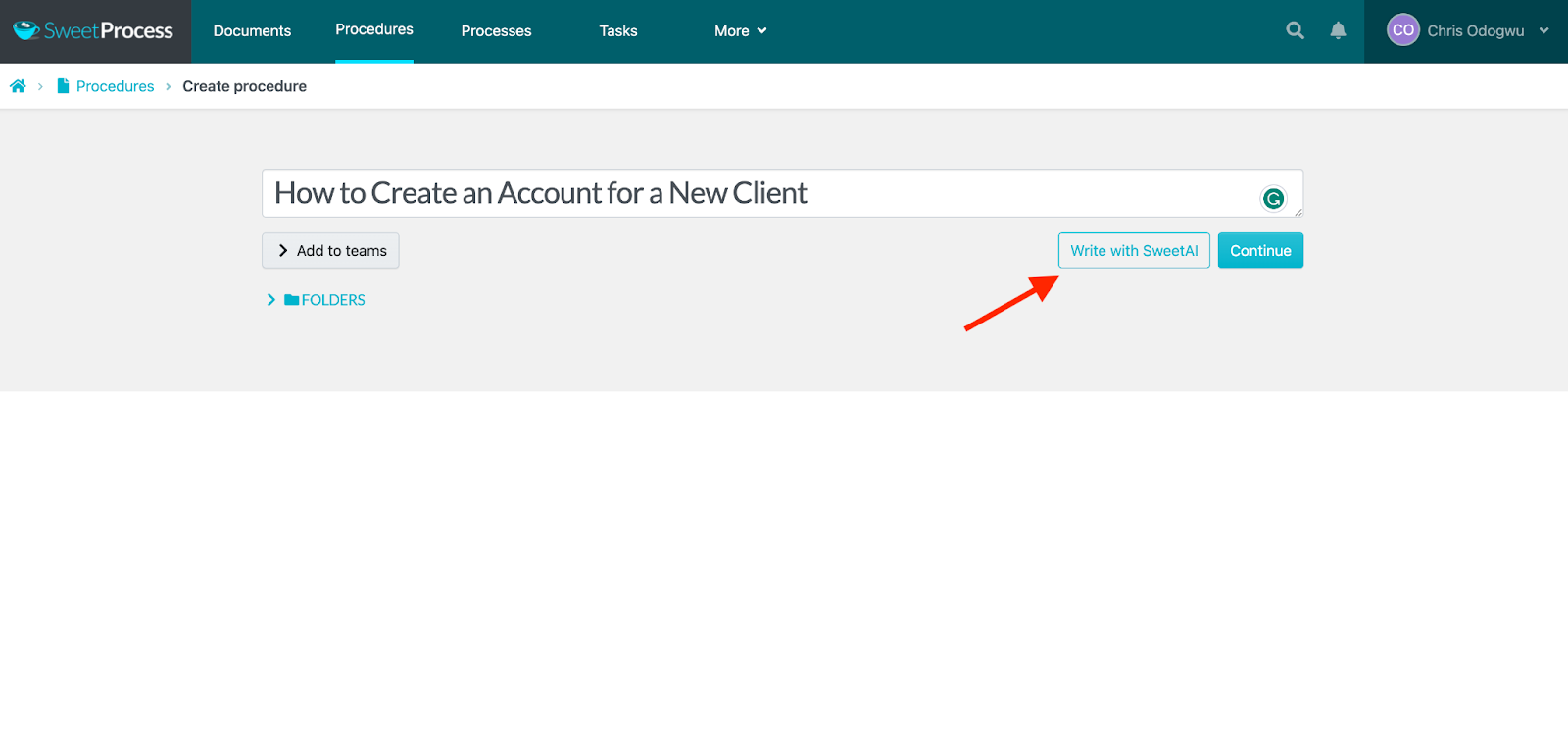

Type the procedure title and click on “Continue.”

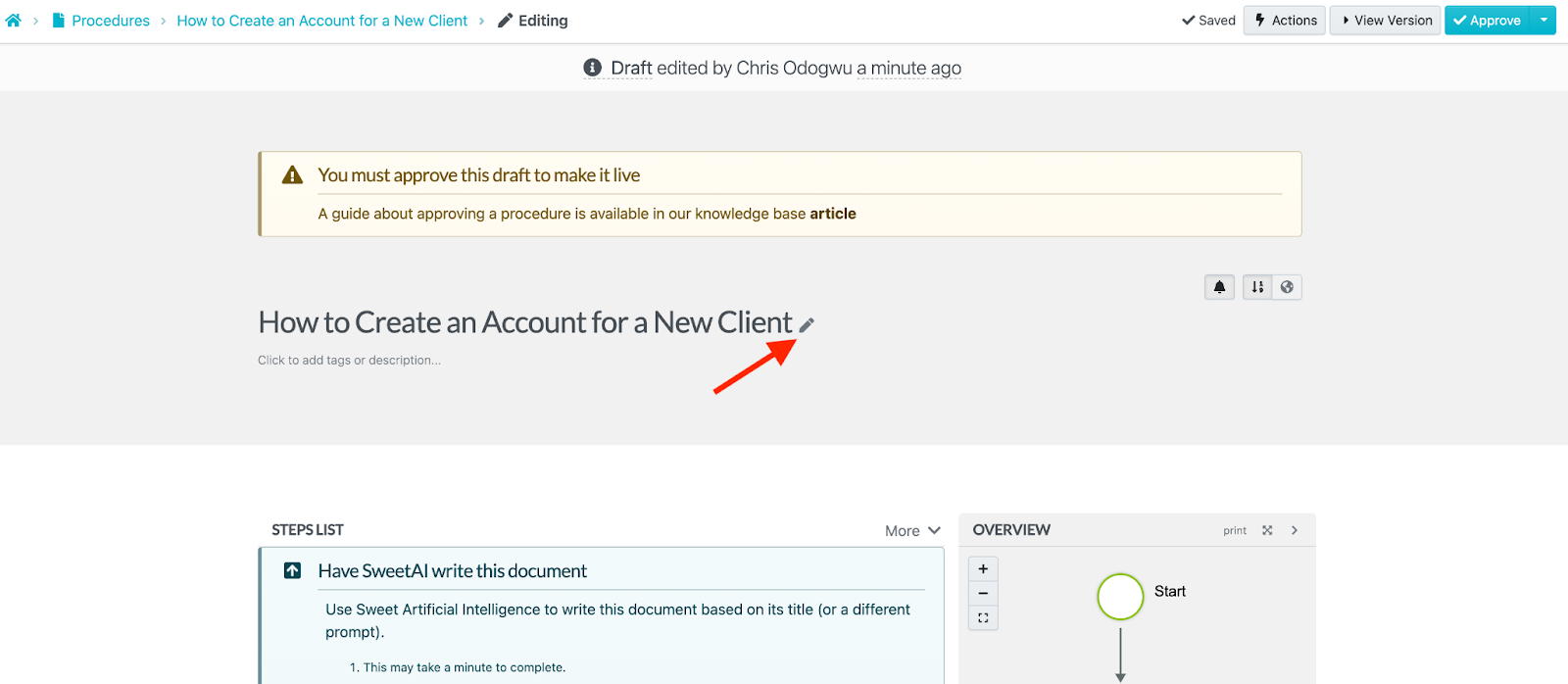

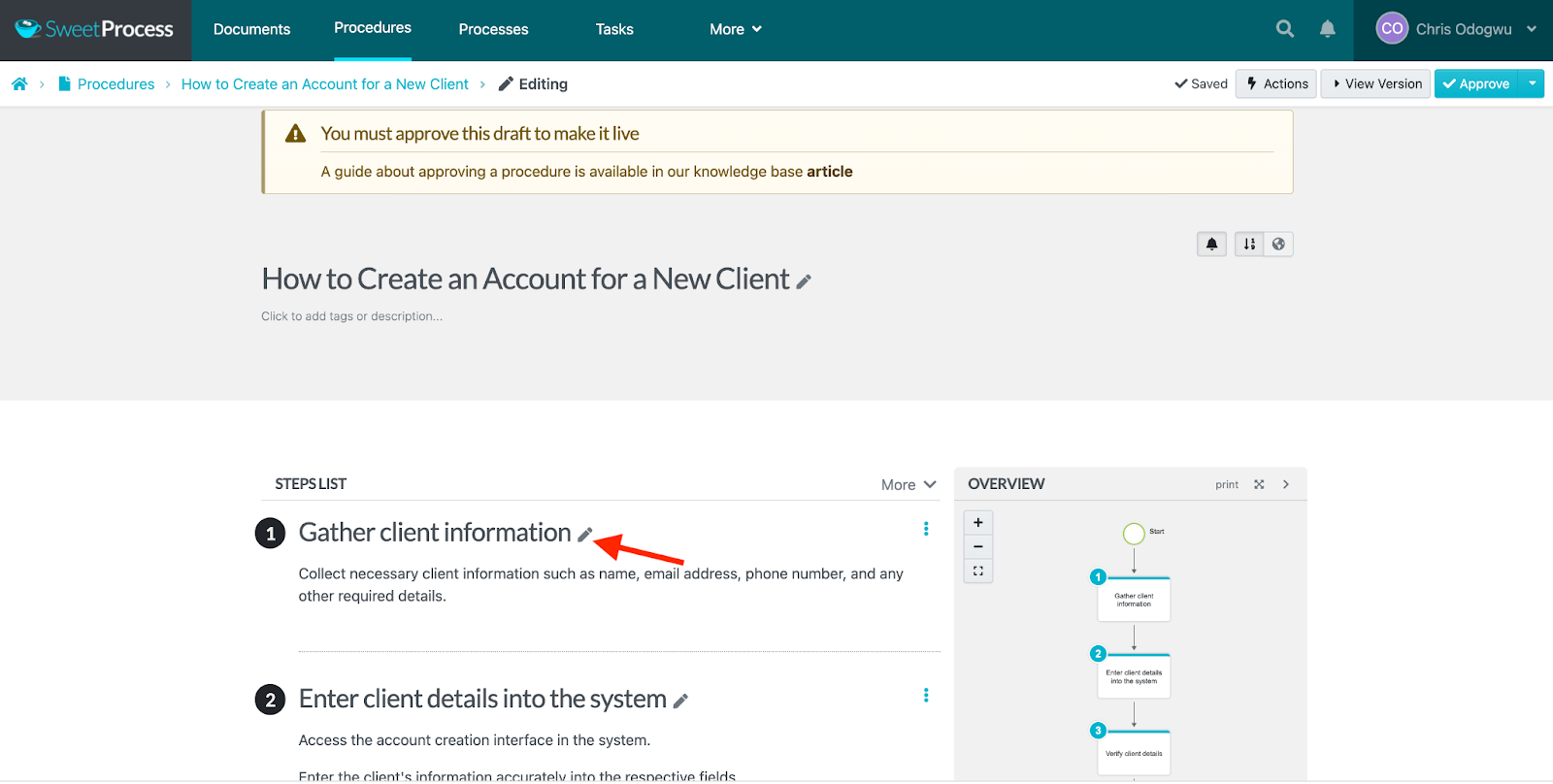

Click the pencil icon beside the title.

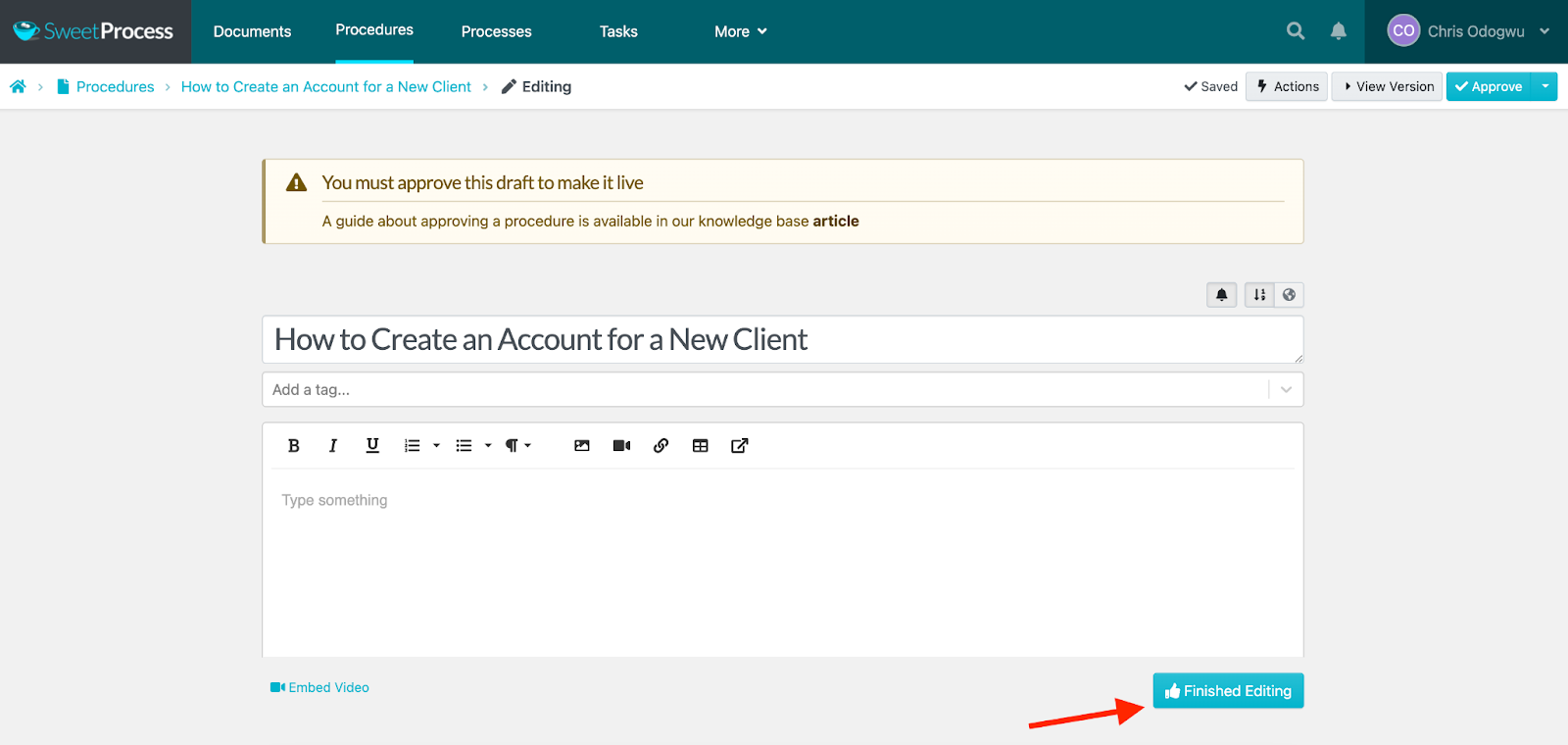

Enter the procedure details and click “Finished Editing.”

How to Document a Procedure in SweetProcess Automatically With SweetAI

Click “Procedures” and “Create Procedure.”

Enter the procedure title and click “Write with SweetAI.”

Click the pencil icon to edit the content.

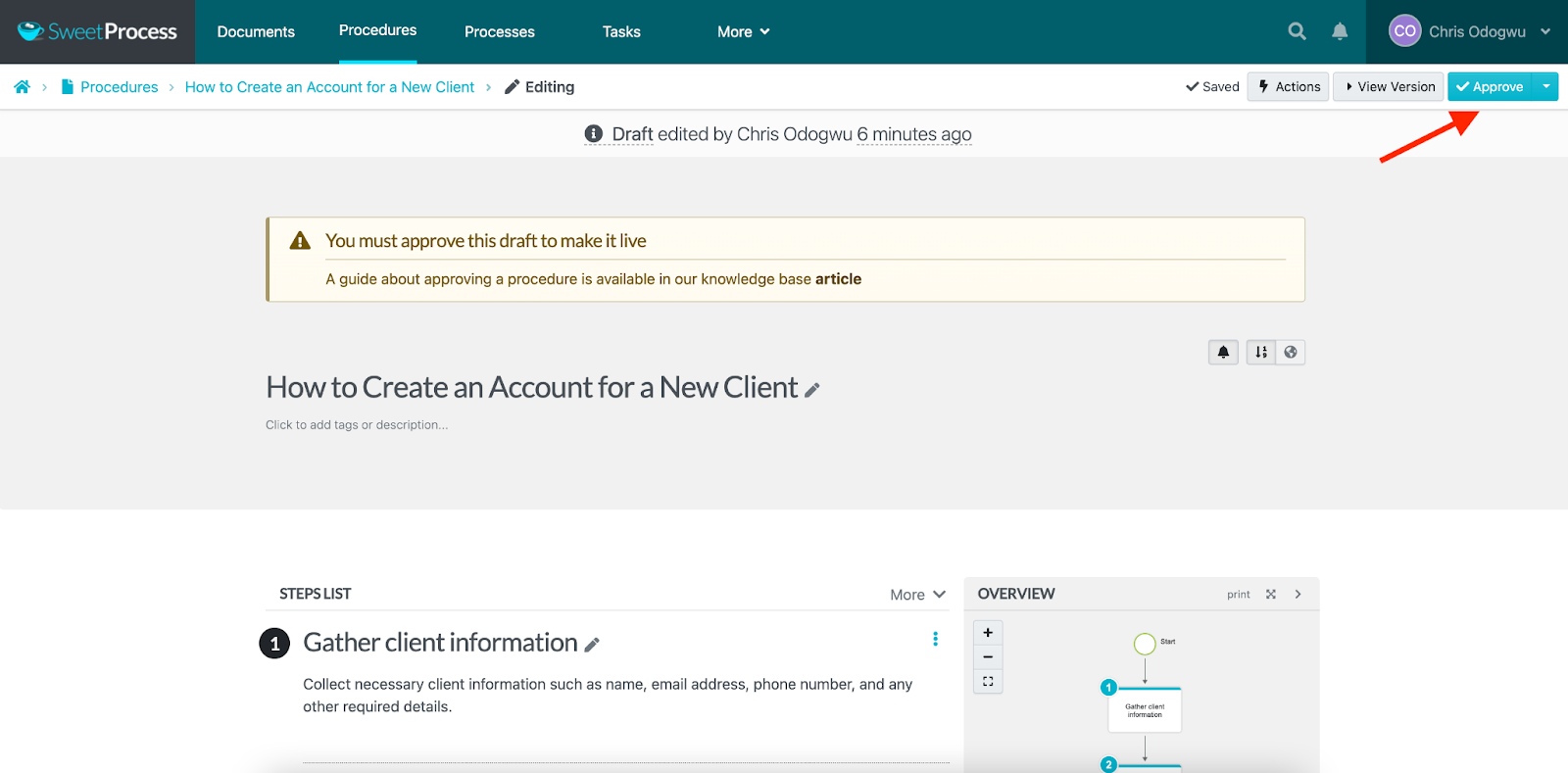

Click “Approve” to publish the document.

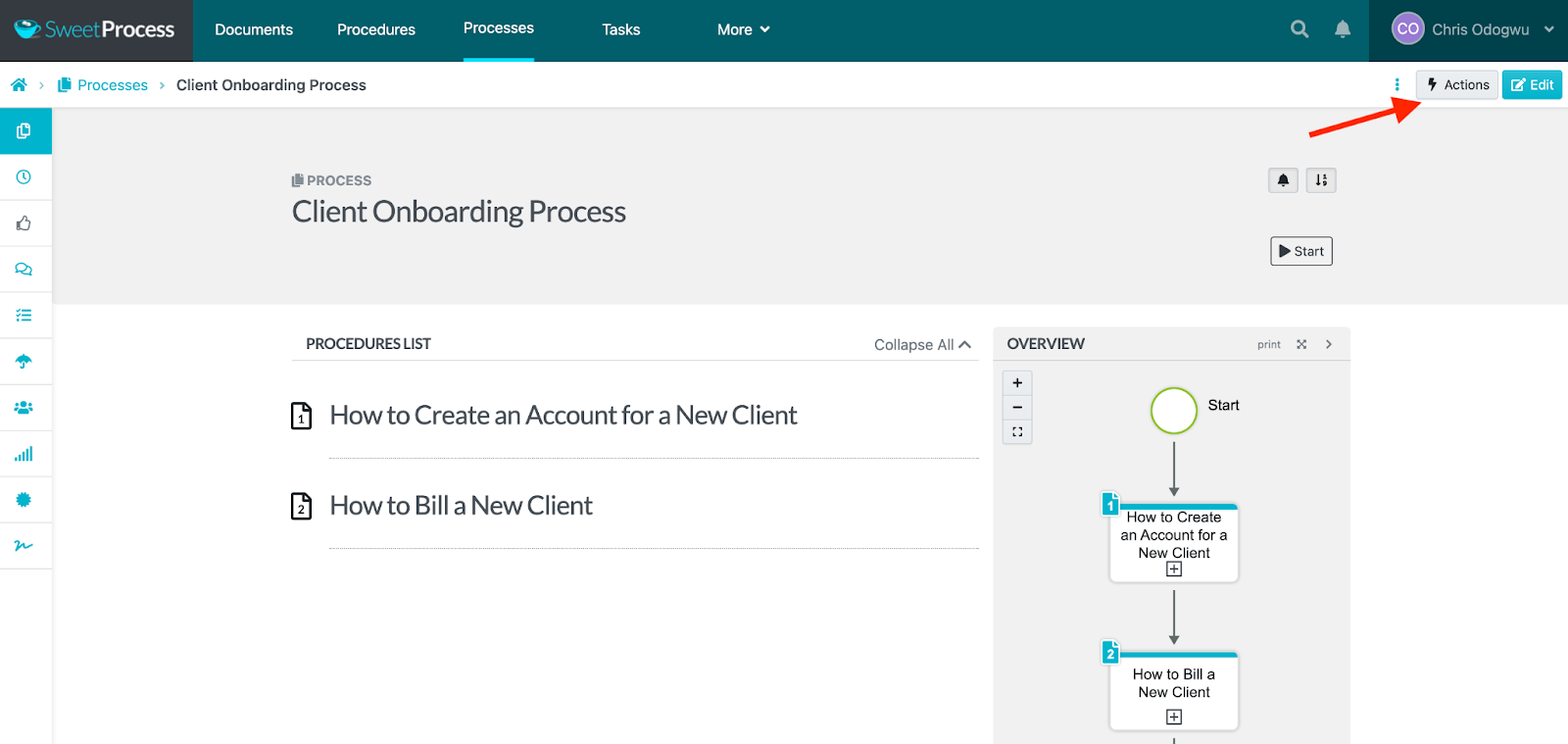

Turn Procedures Into Processes

Some tasks entail combining several procedures to create a process. SweetProcess allows you to do that seamlessly by adding the procedures with the click of a tab.

How to Turn Procedures Into Processes in SweetProcess

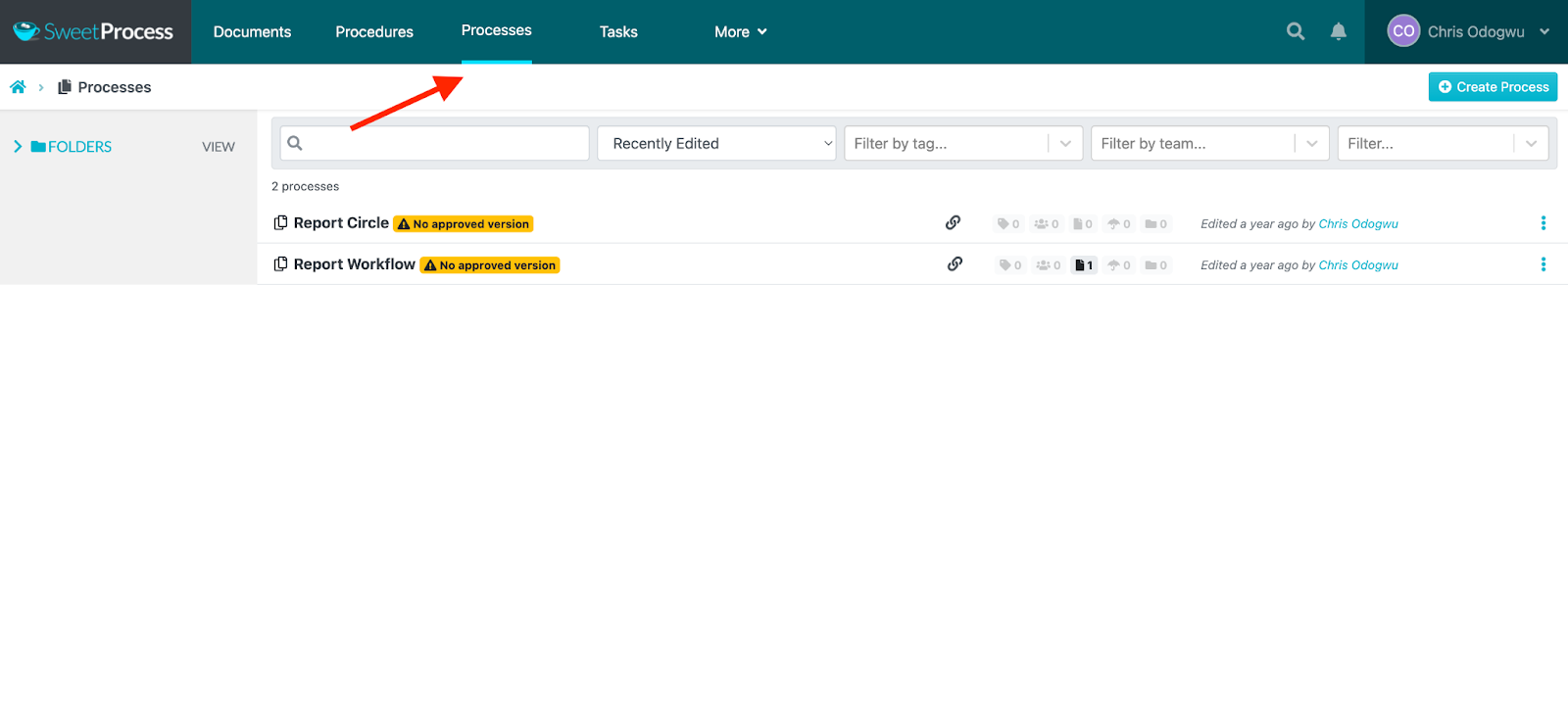

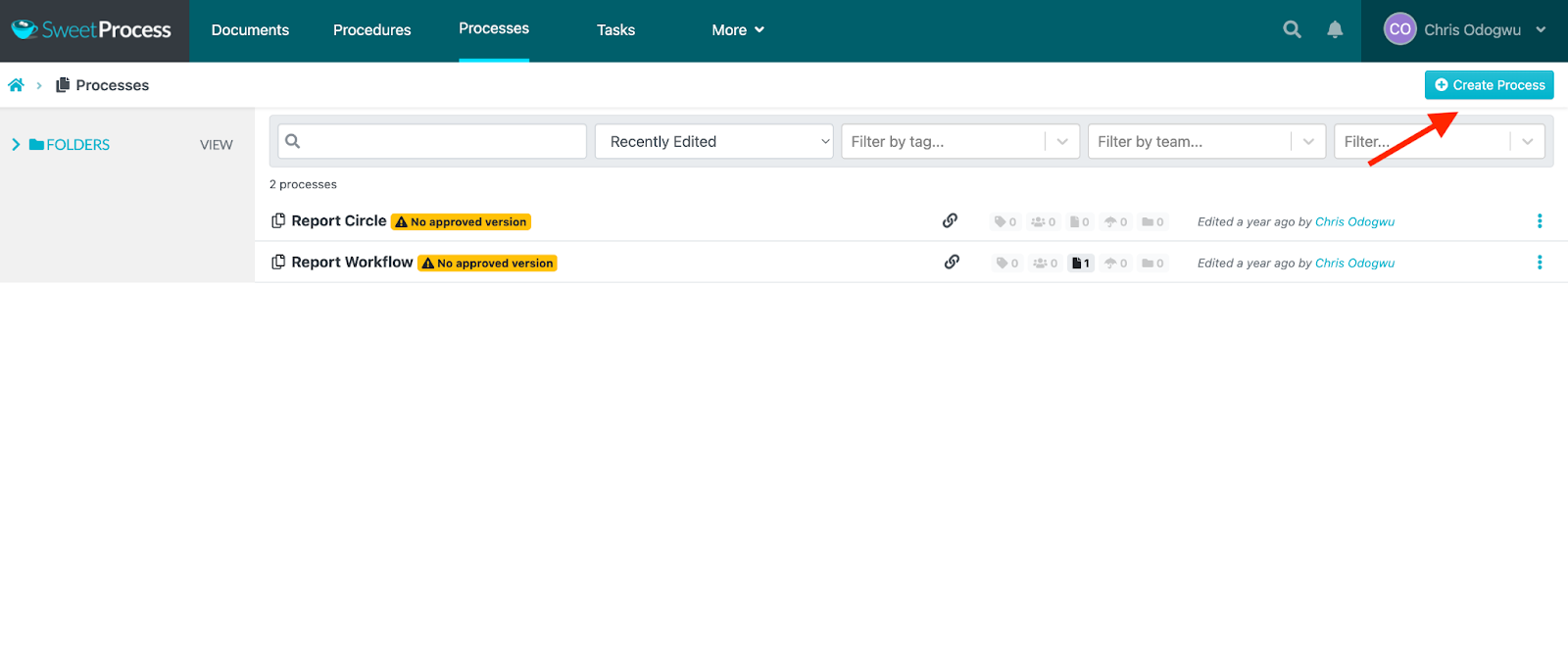

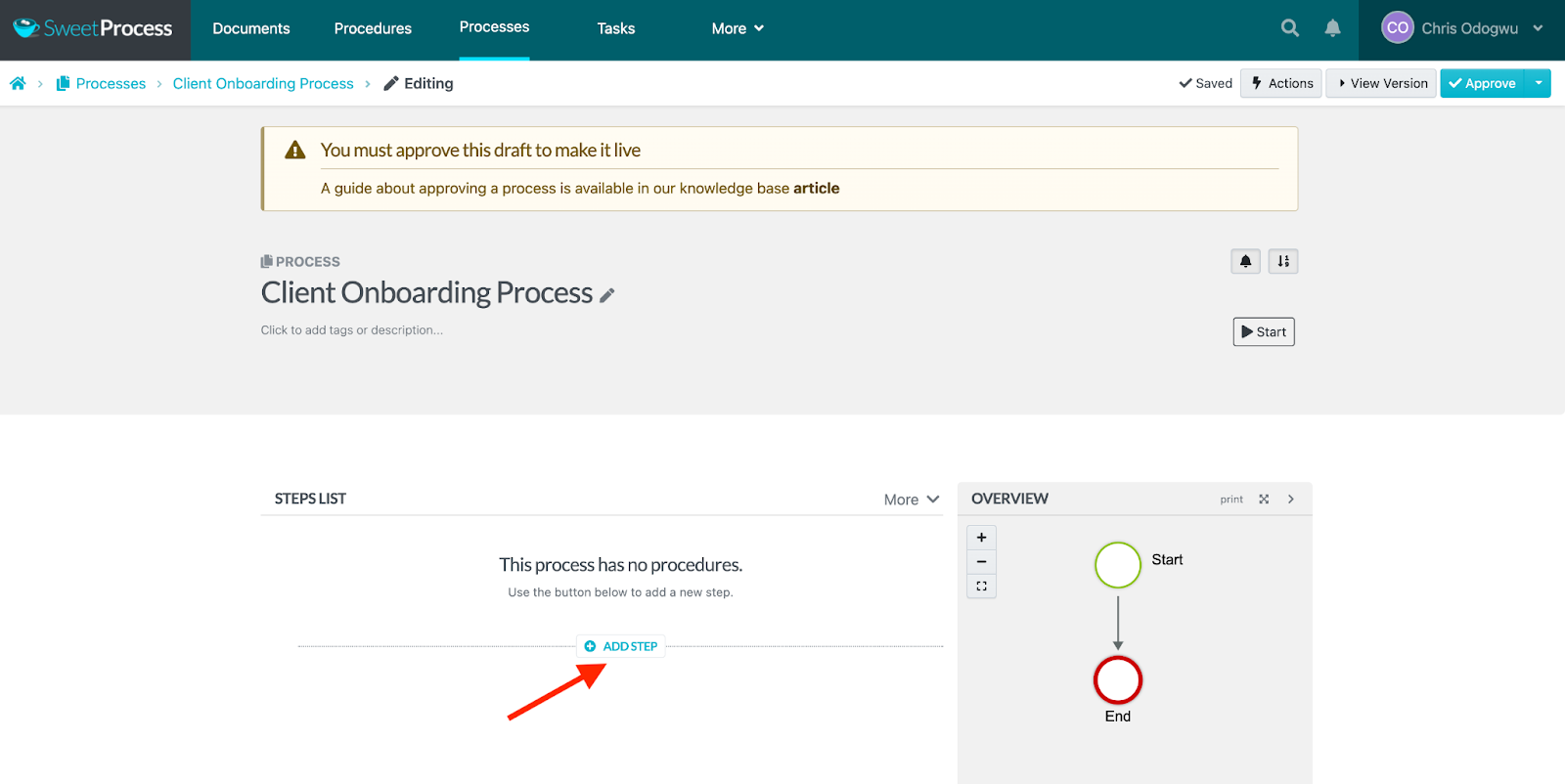

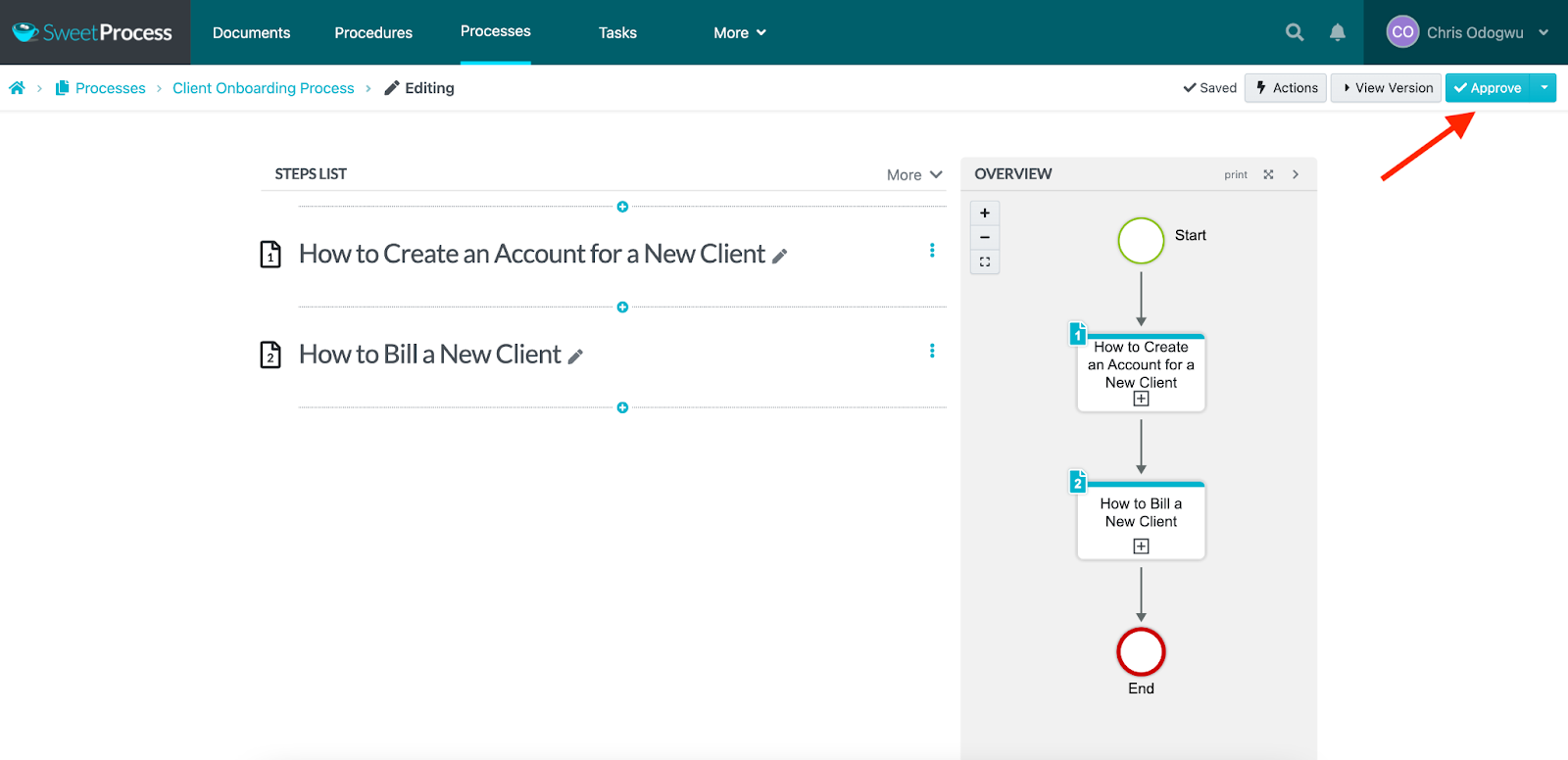

Click “Processes” and “Create Process.”

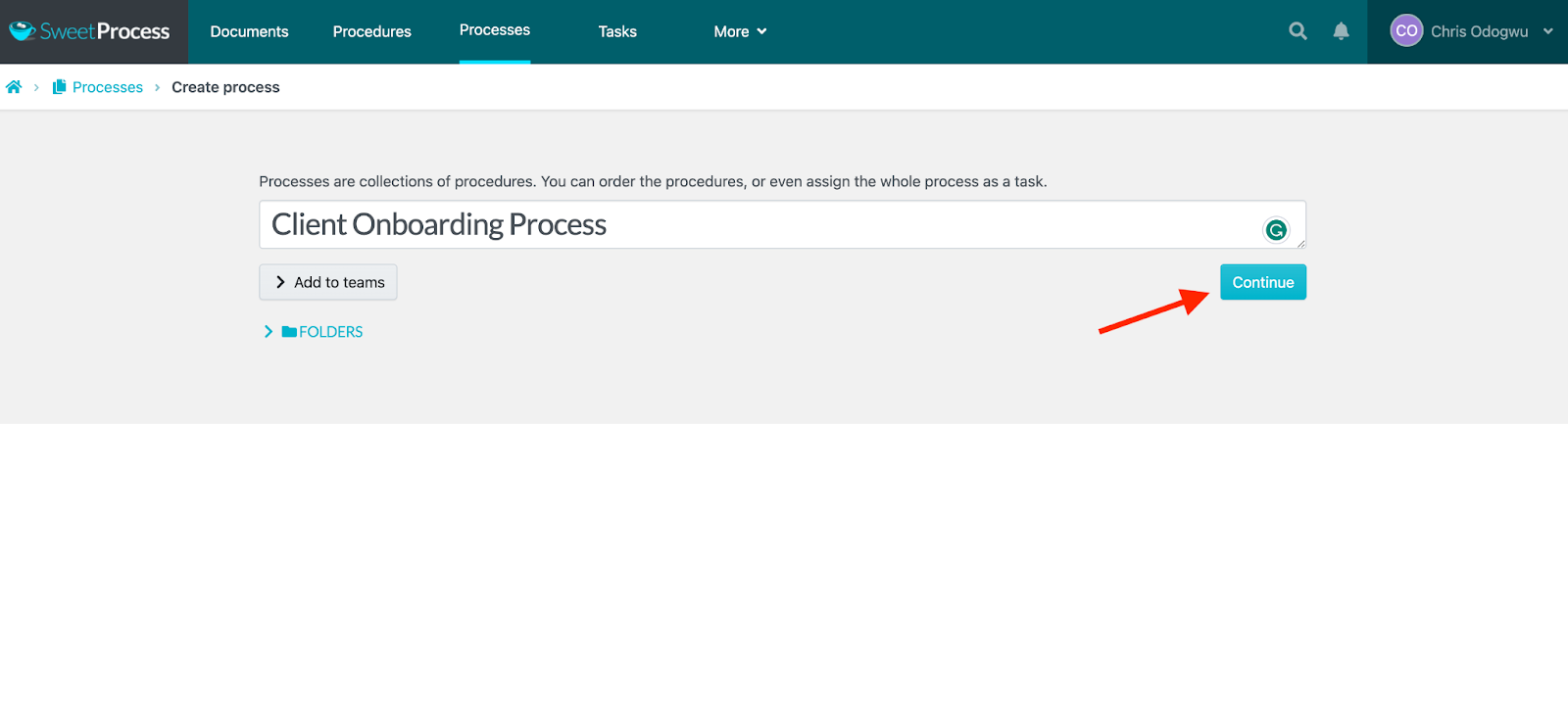

Type the process title and click “Continue.”

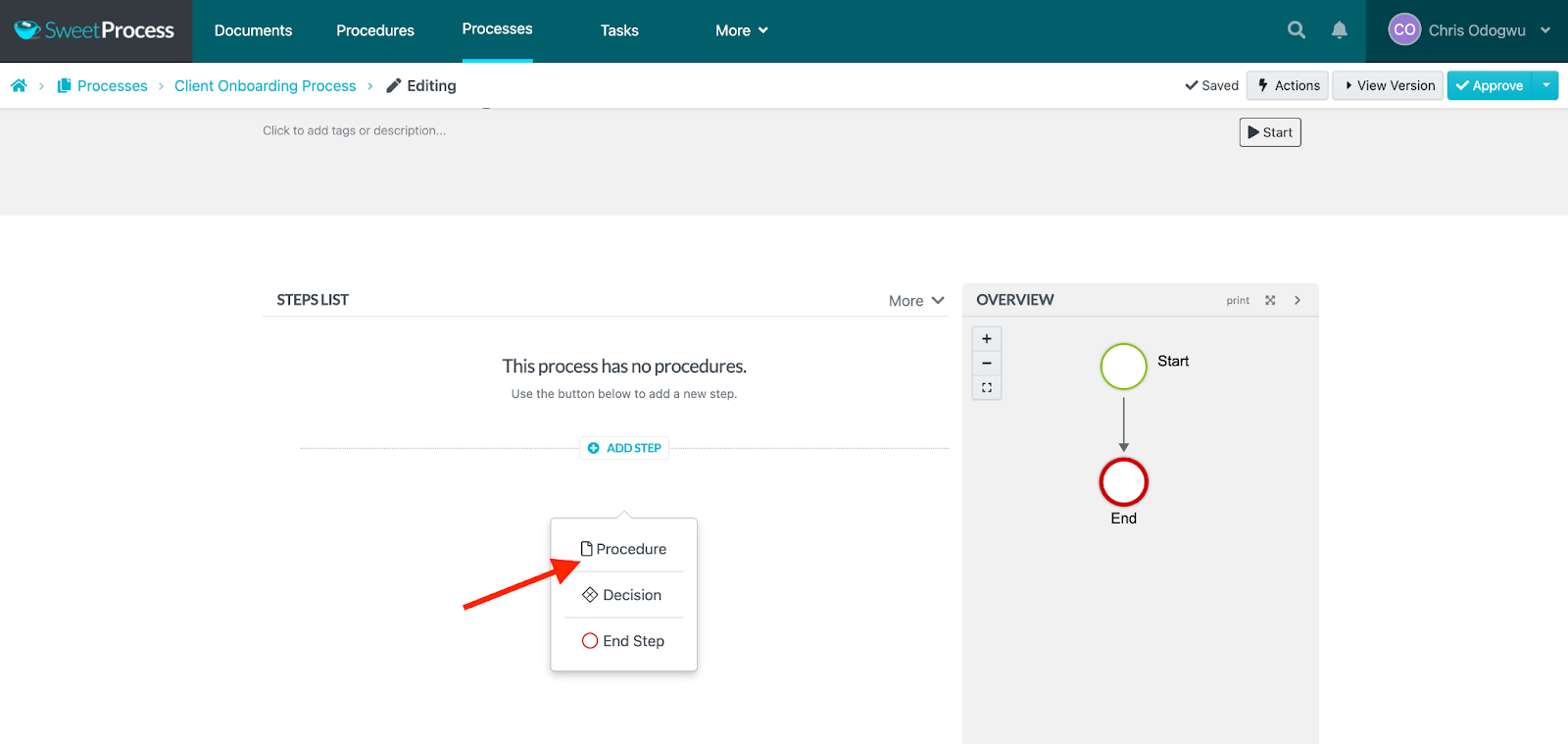

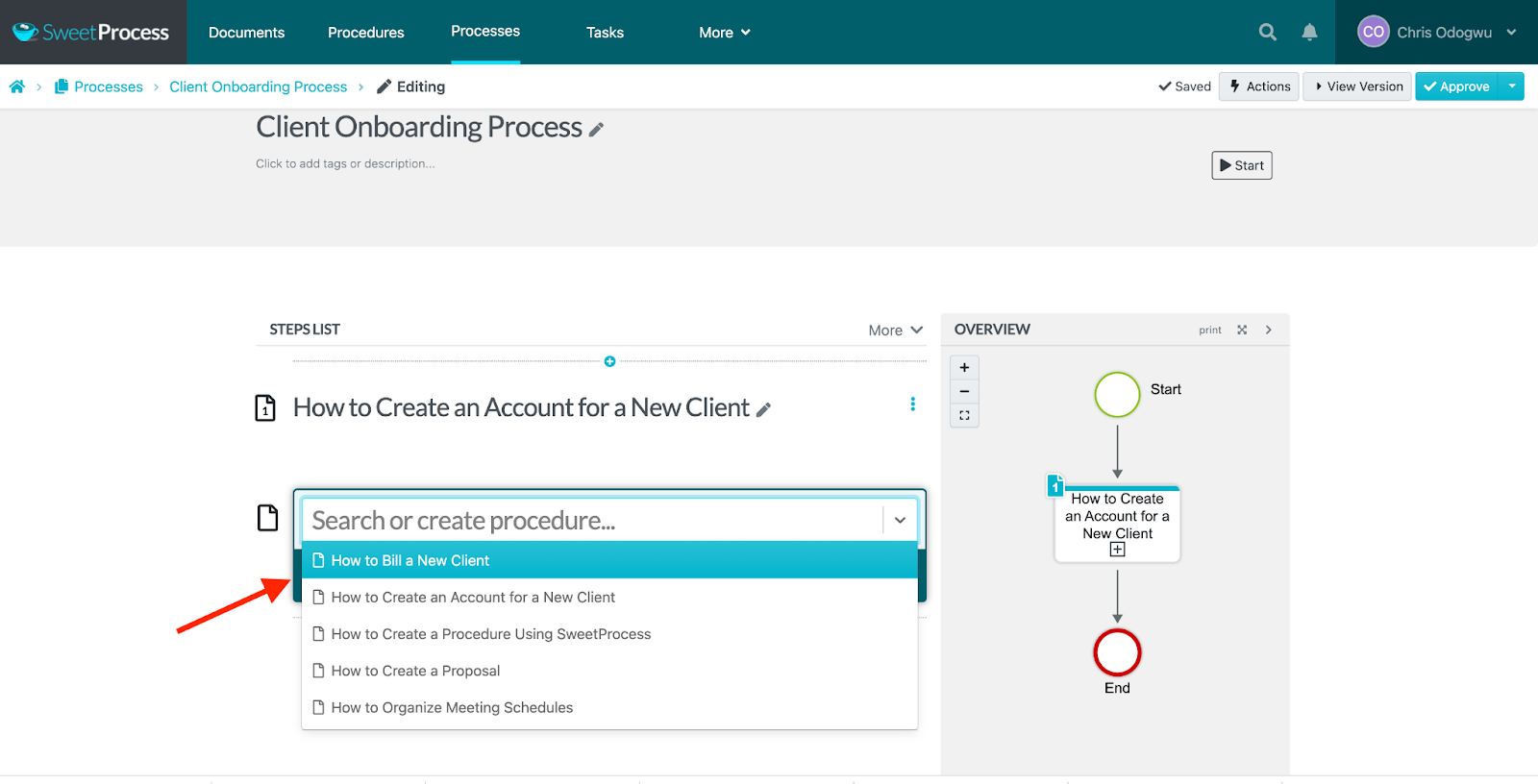

Click “Add Step.”

Click “Procedure.”

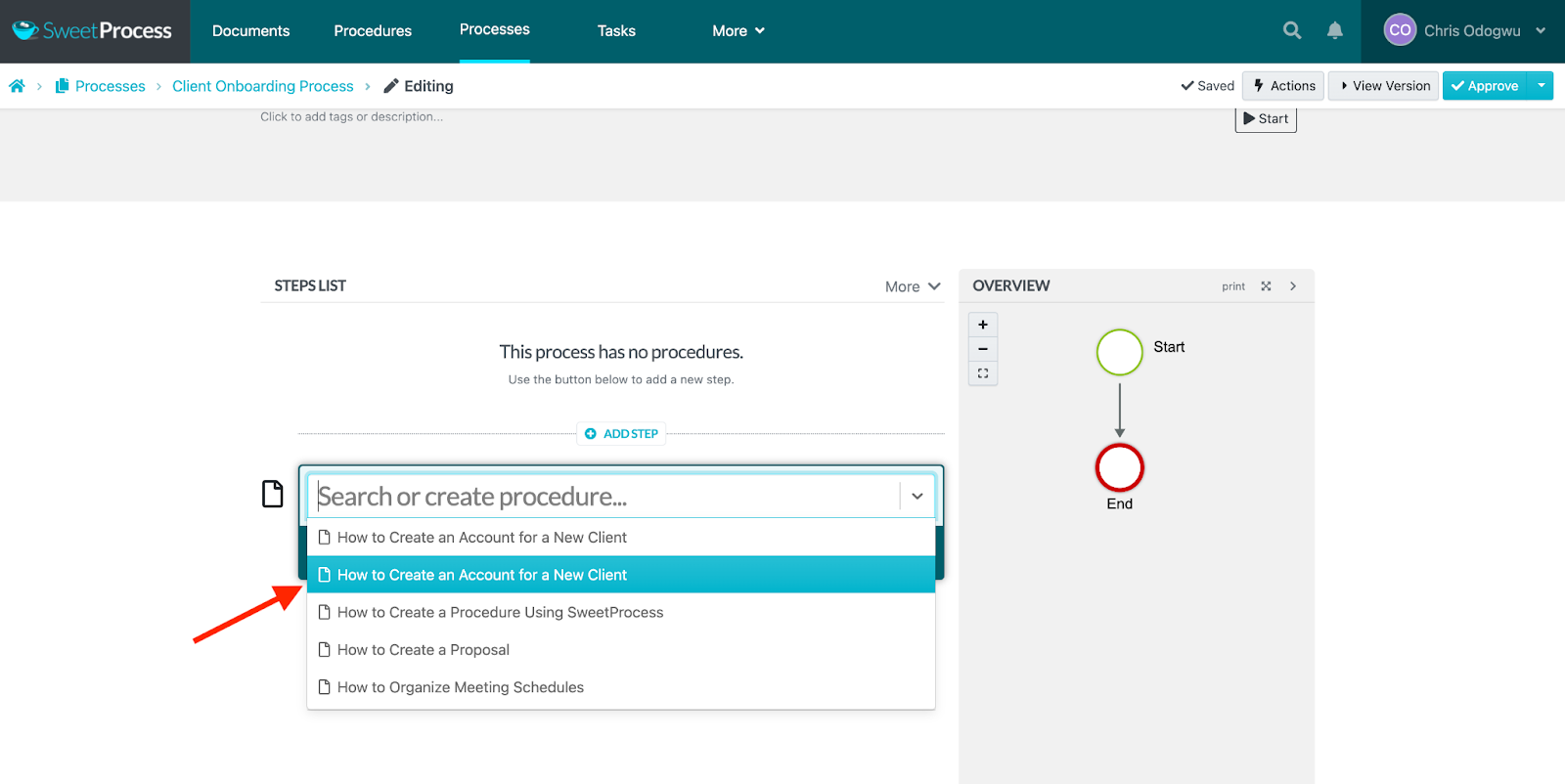

Select the procedure from the menu.

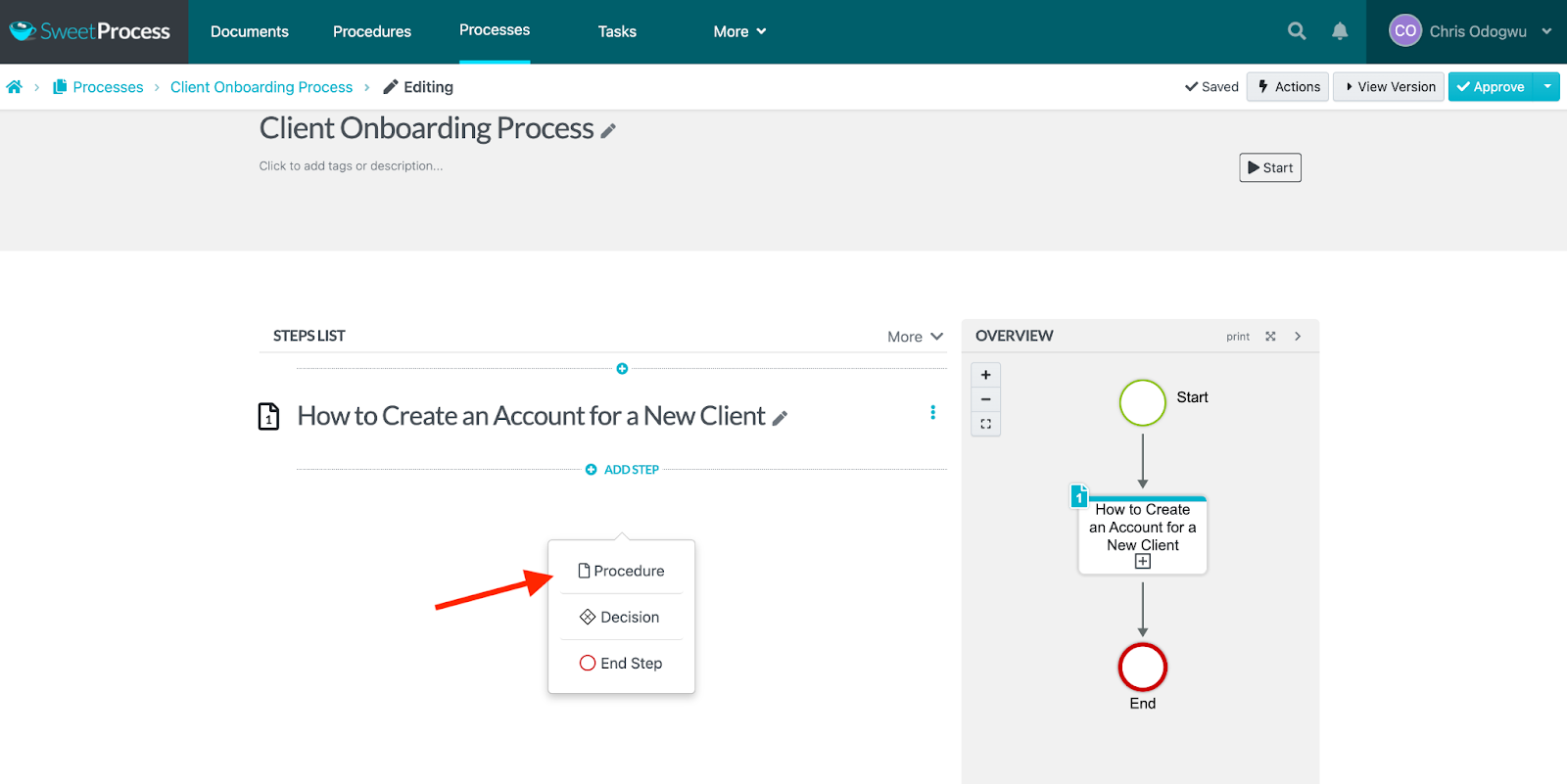

Click “Add Step” and “Procedure.”

Click “Approve” to publish your process.

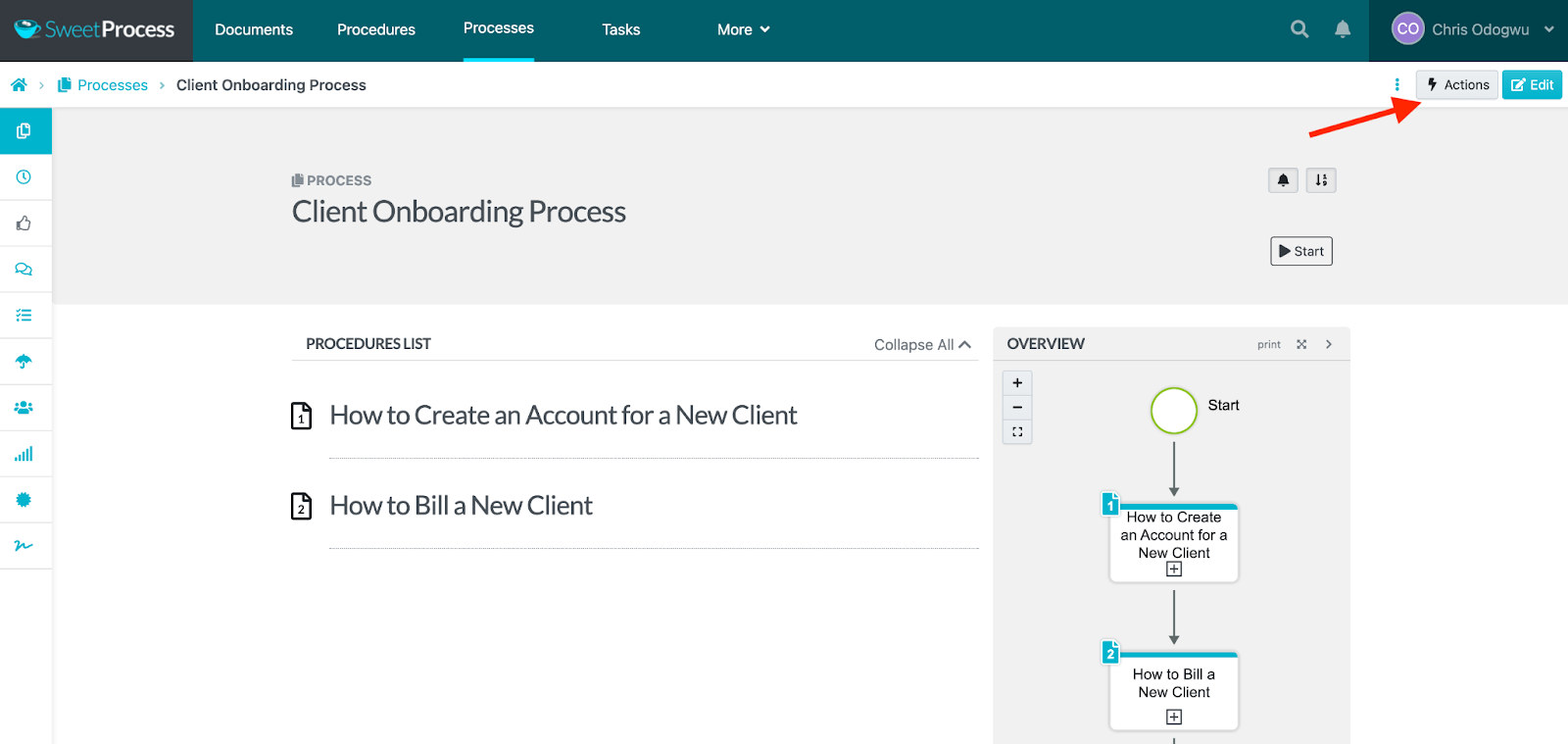

SweetProcess automatically creates a chart for processes created. The image on the right side of the above screenshot is an example. Each procedure you add to the processes is added to the chart from start to finish.

Turn Procedures and Processes Into Actionable Tasks

Procedures and processes in SweetProcess can be maximized for various tasks based on your business needs.

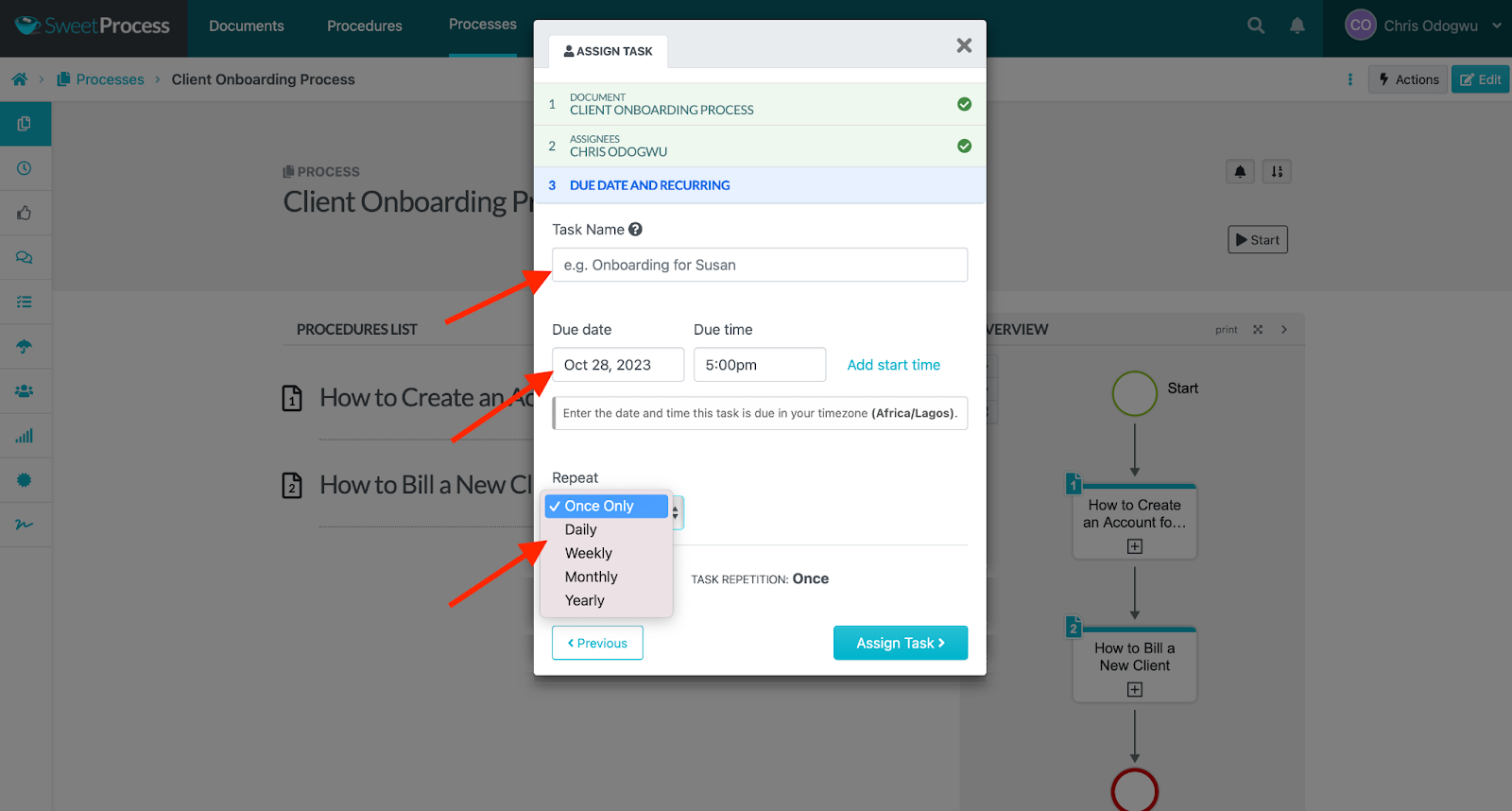

How to Turn Procedures and Processes Into Actionable Tasks

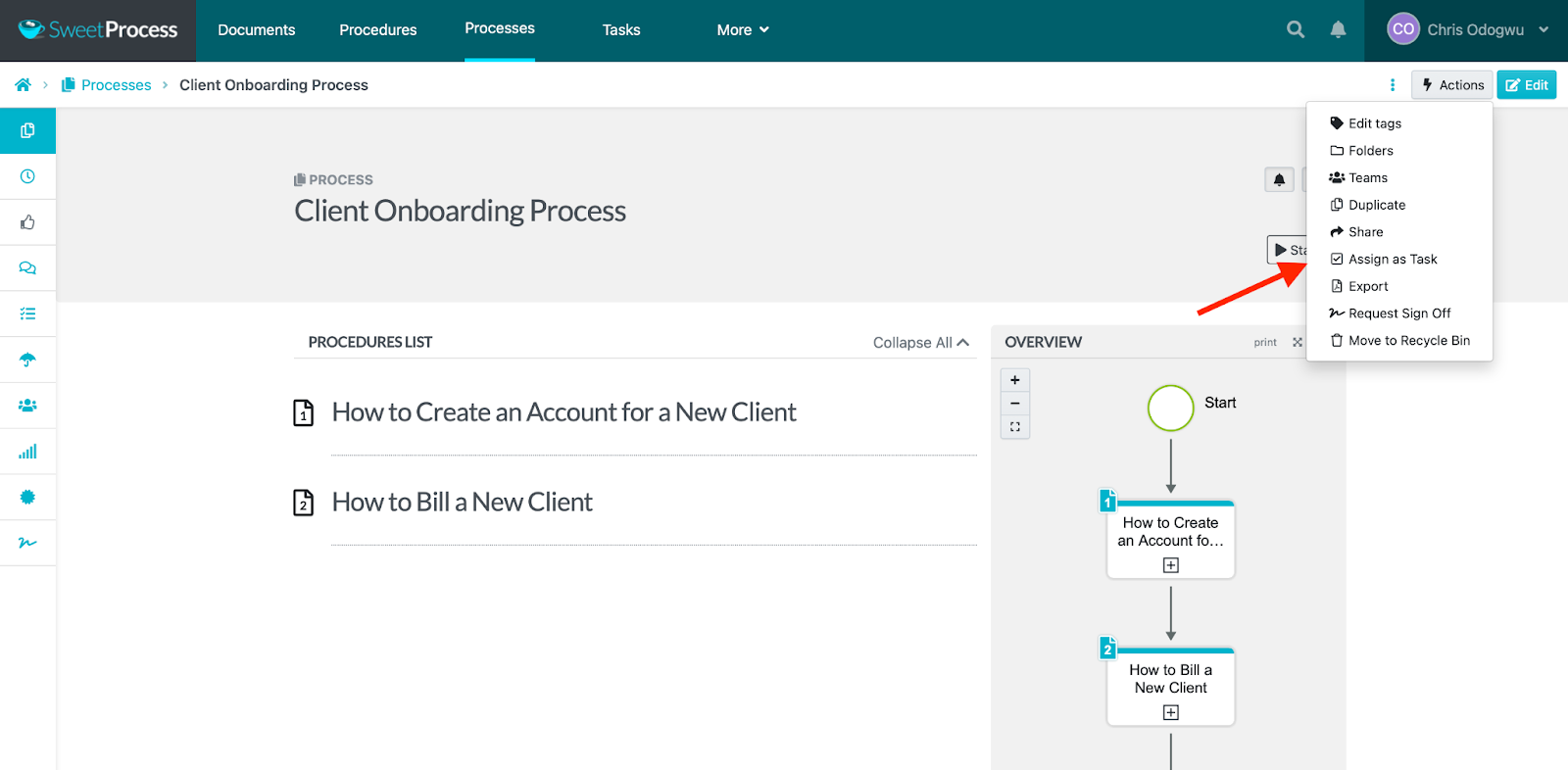

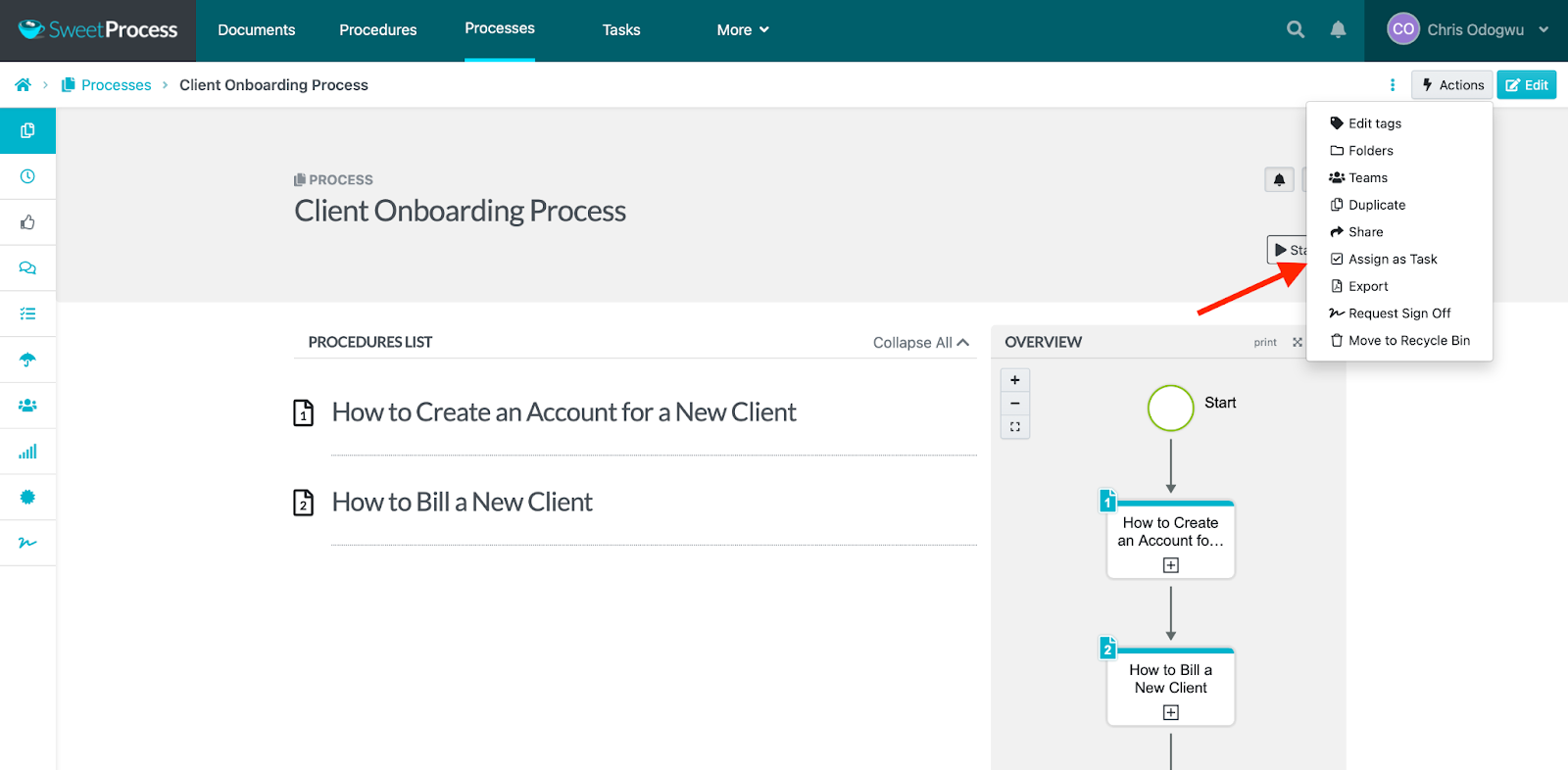

Navigate to the procedure or process and click “Actions.”

Select any task you want to perform from the drop-down menu.

Create a Quiz to Assess Your Team’s Grasp of Company Policies, Procedures, and Processes

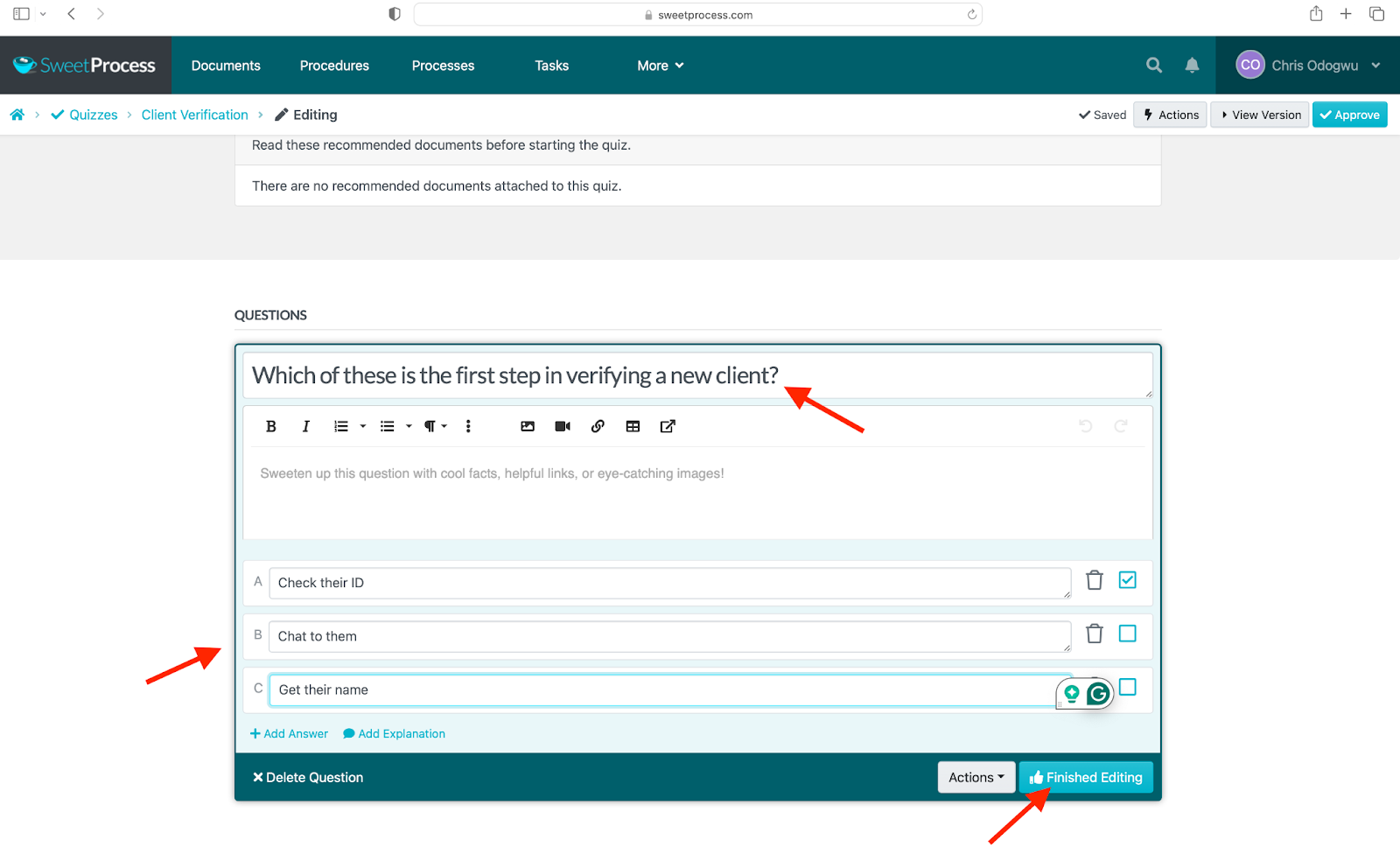

After introducing new policies, procedures, and processes to employees, confirming that they understand them is reassuring before assigning tasks. This reduces errors or mistakes to the barest minimum and promotes efficiency. SweetProcess has a quiz feature for testing knowledge with multichoice and open-ended questions. Team members can take the quiz remotely at their convenience.

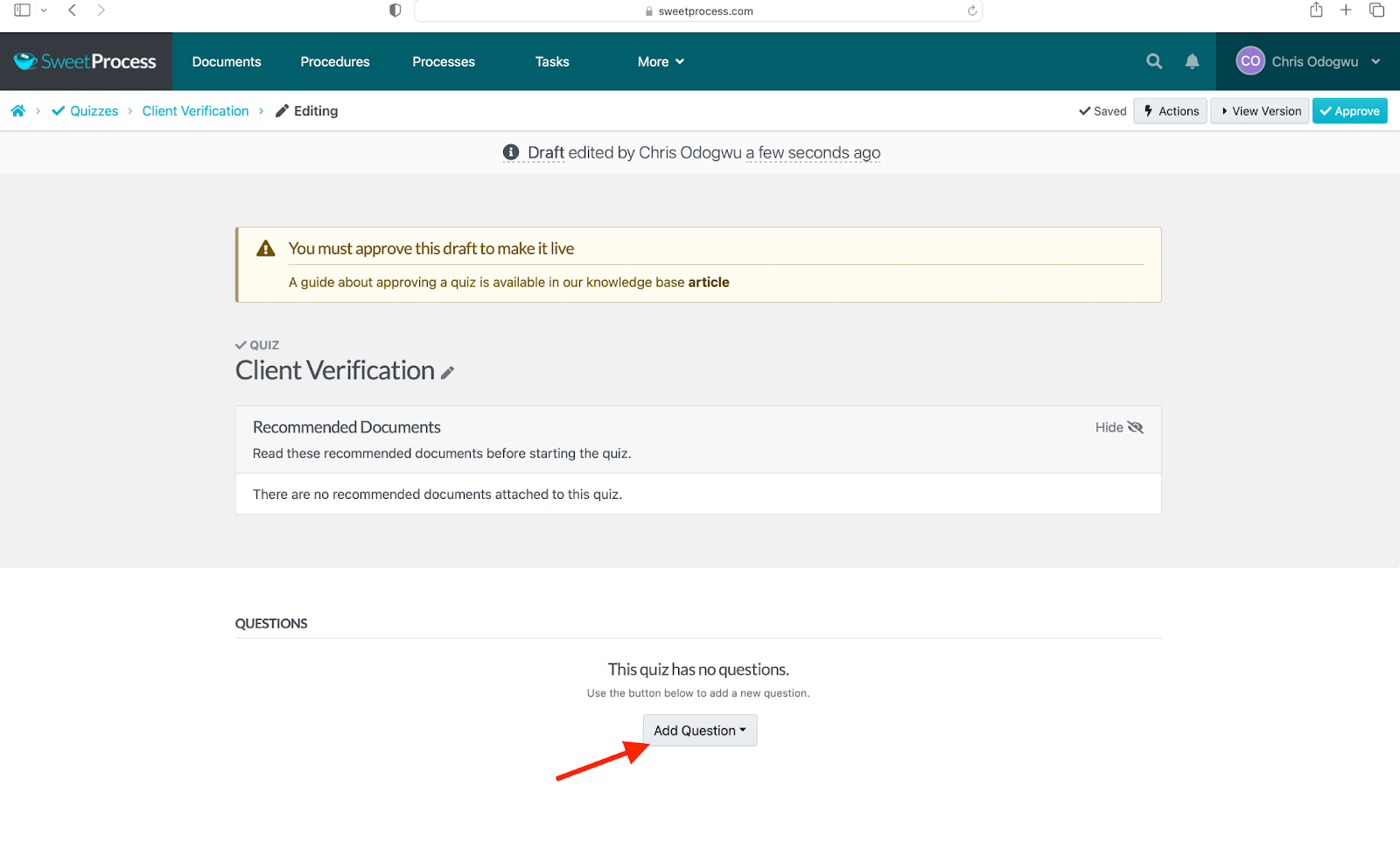

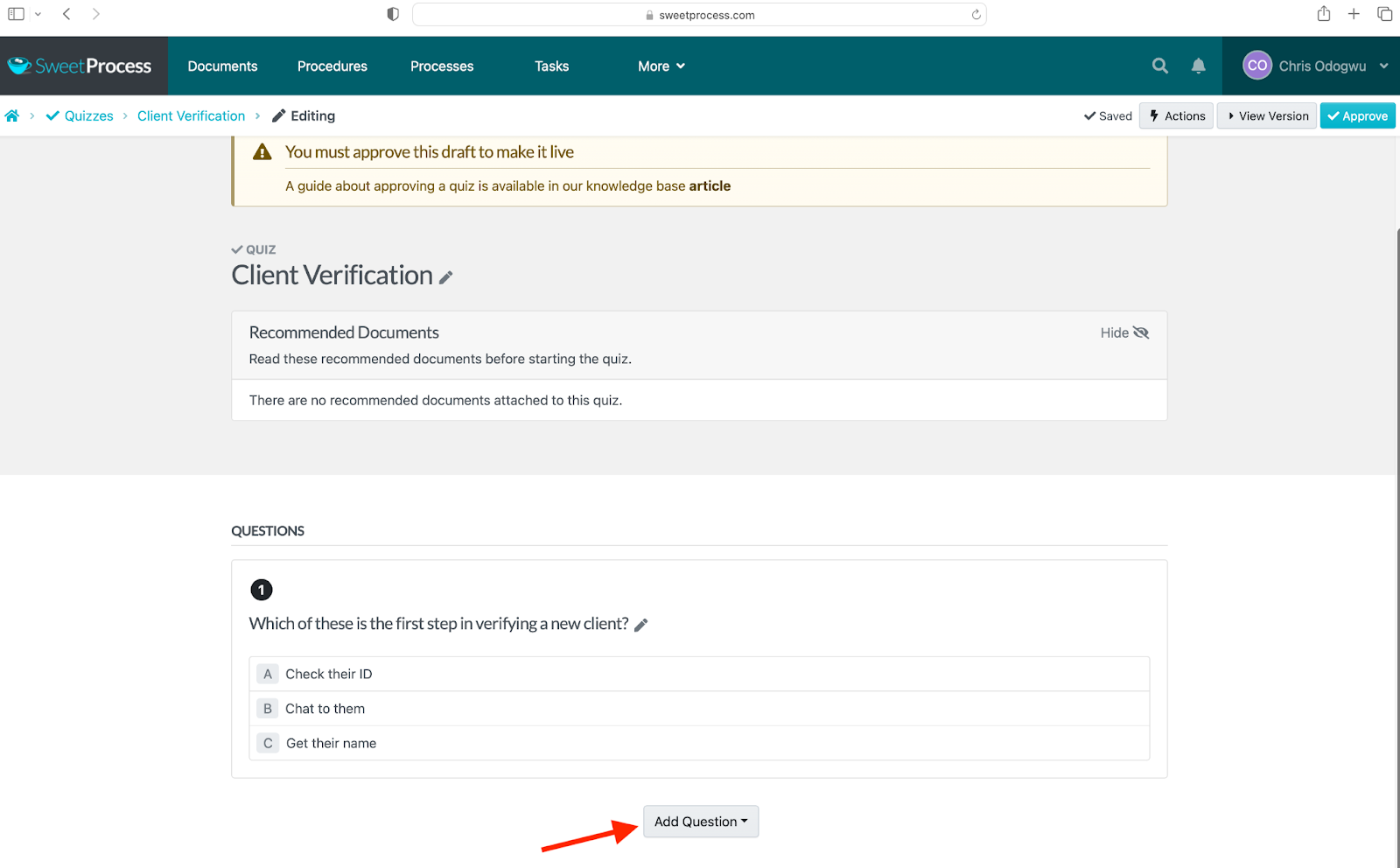

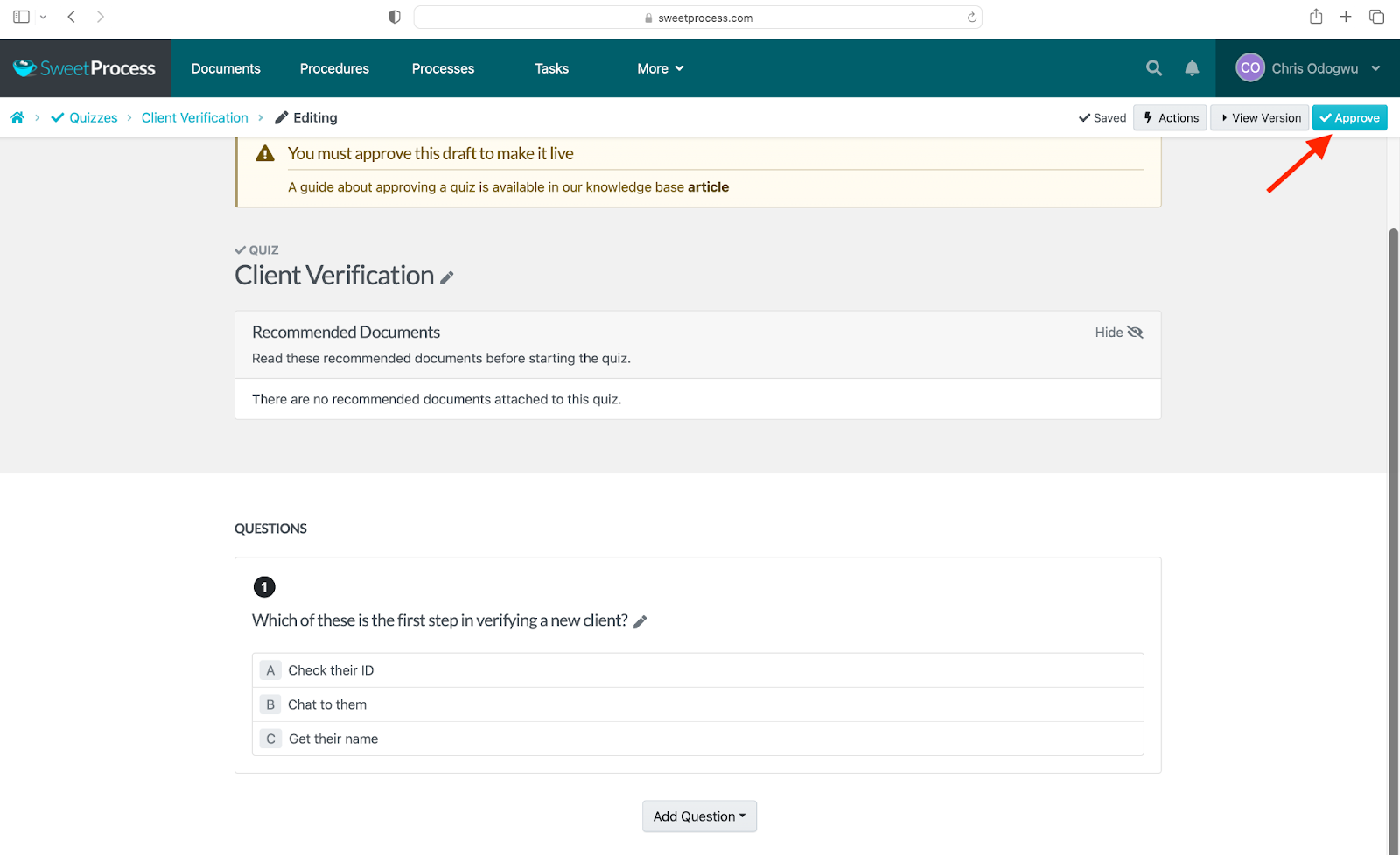

How to Create a Quiz in SweetProcess

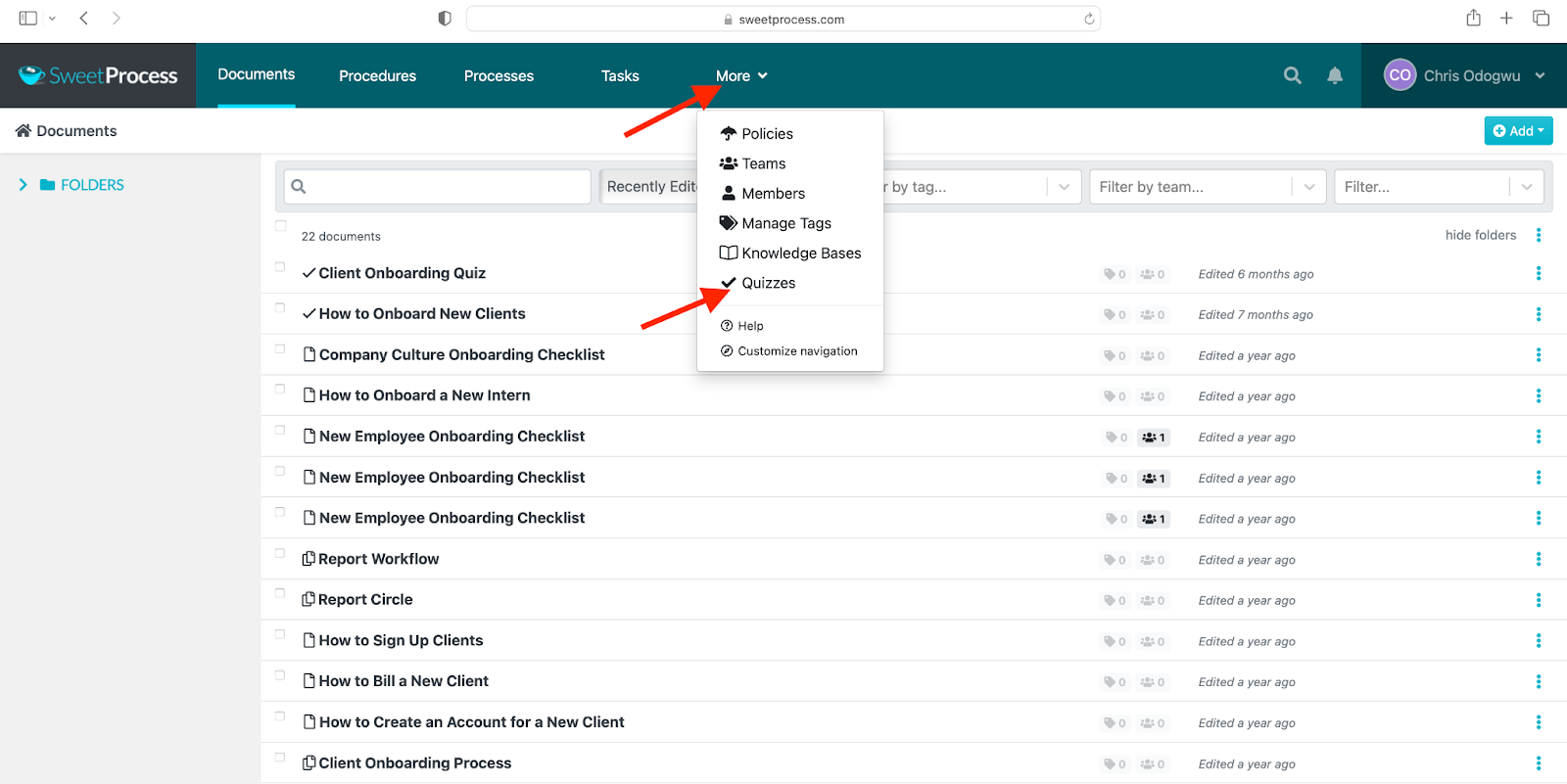

Click “More” and “Quizzes.”

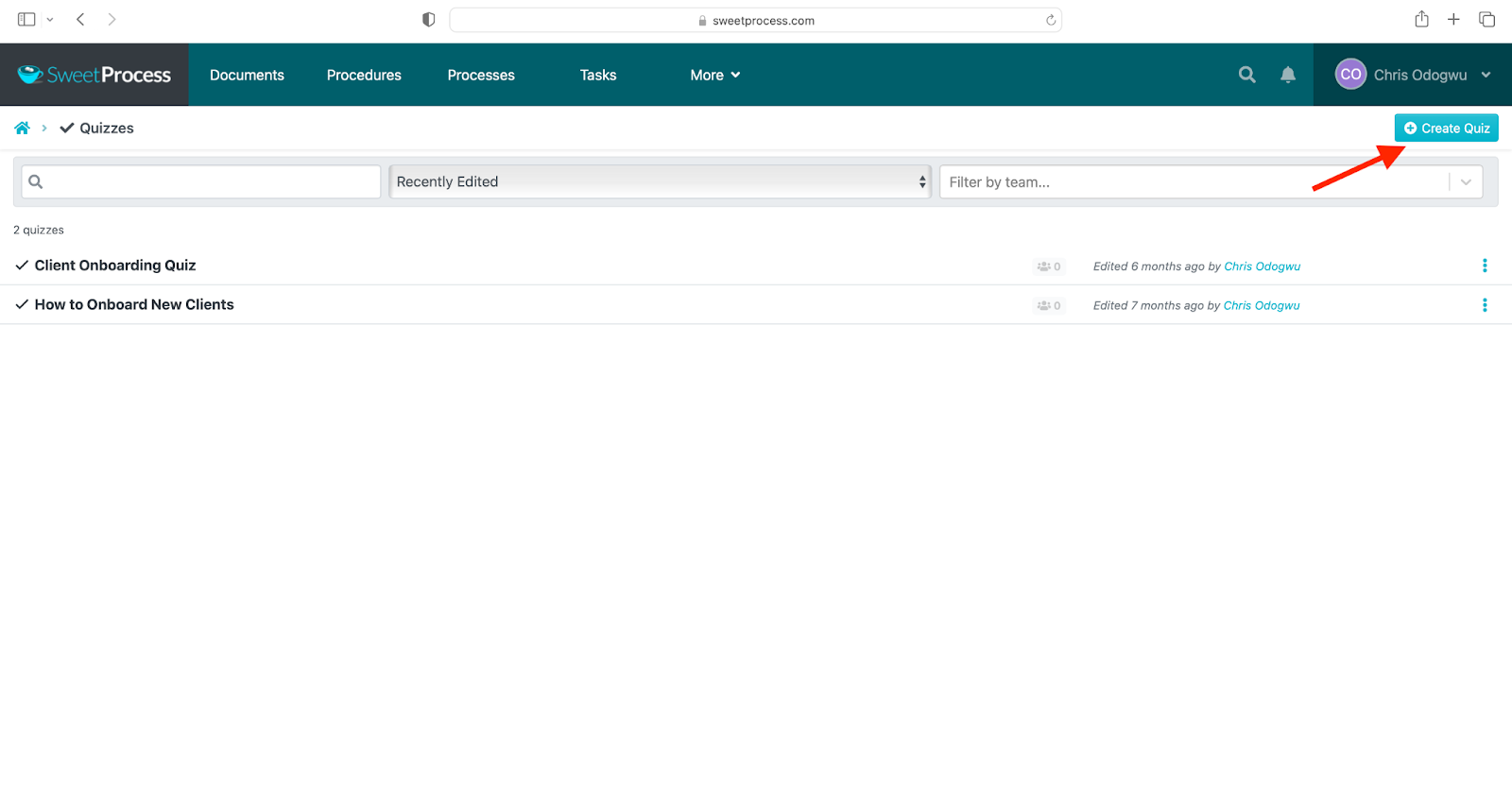

Click “Create Quiz.”

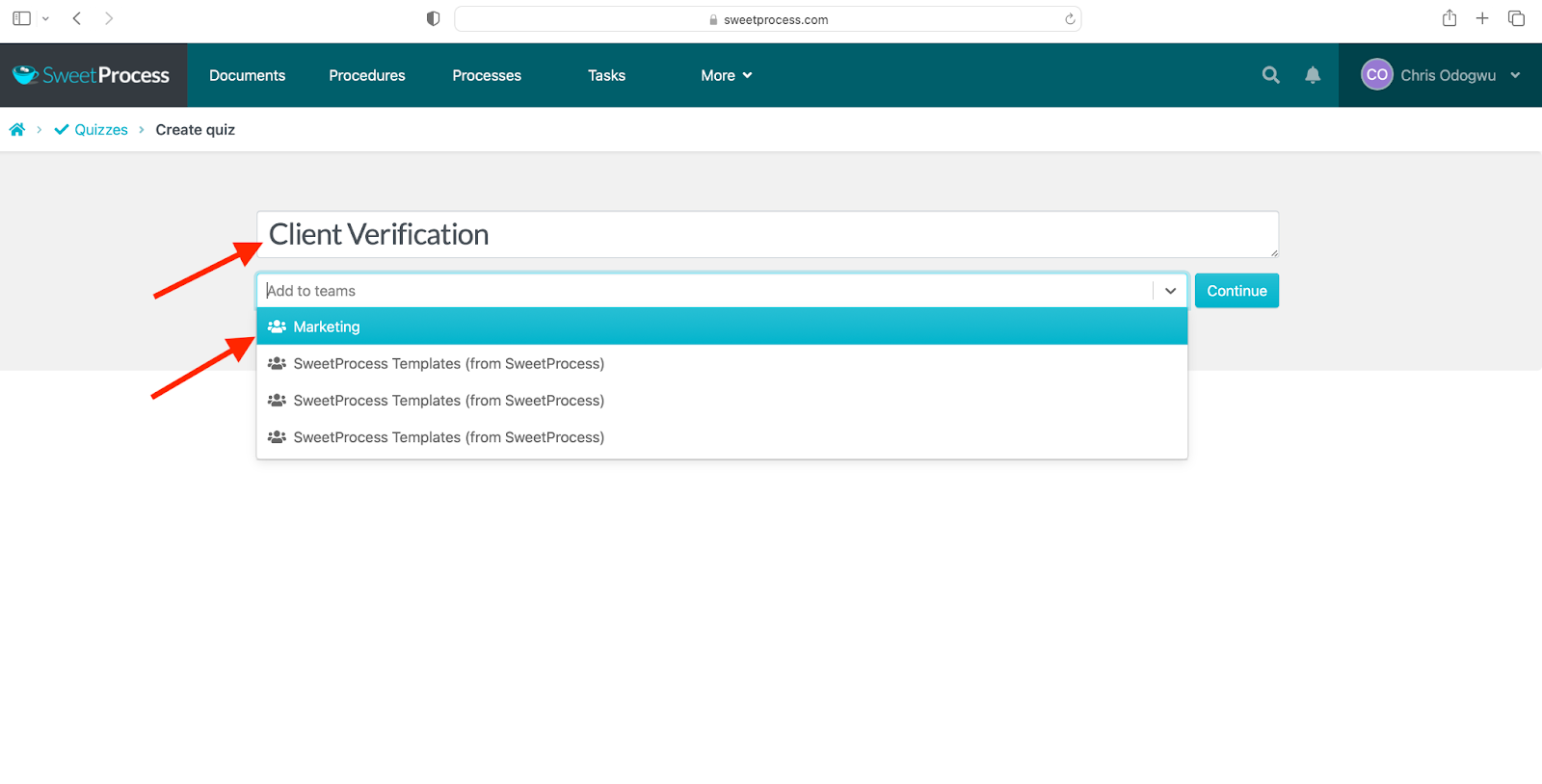

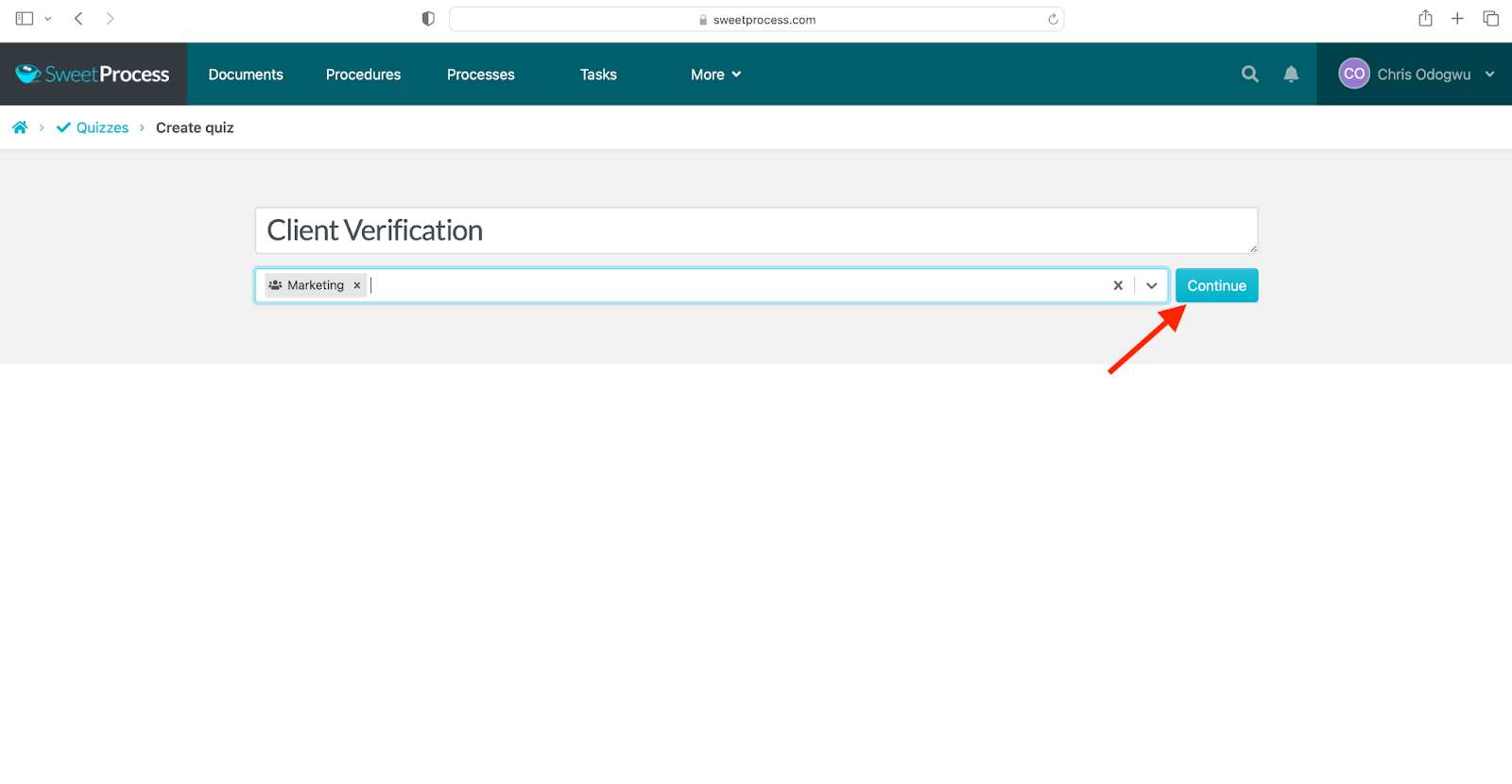

Enter the quiz title, select a team from the drop-down menu, and click “Continue.”

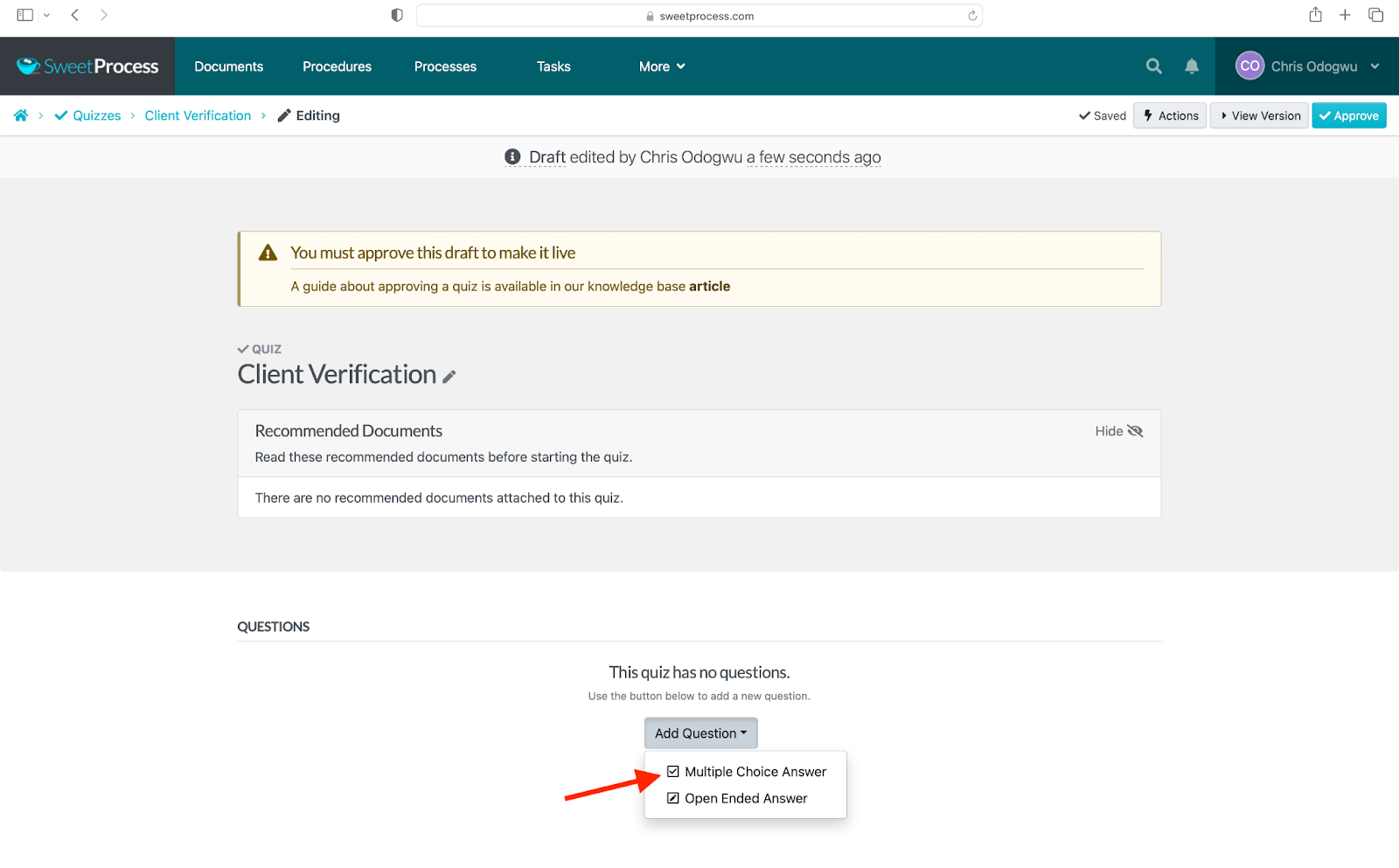

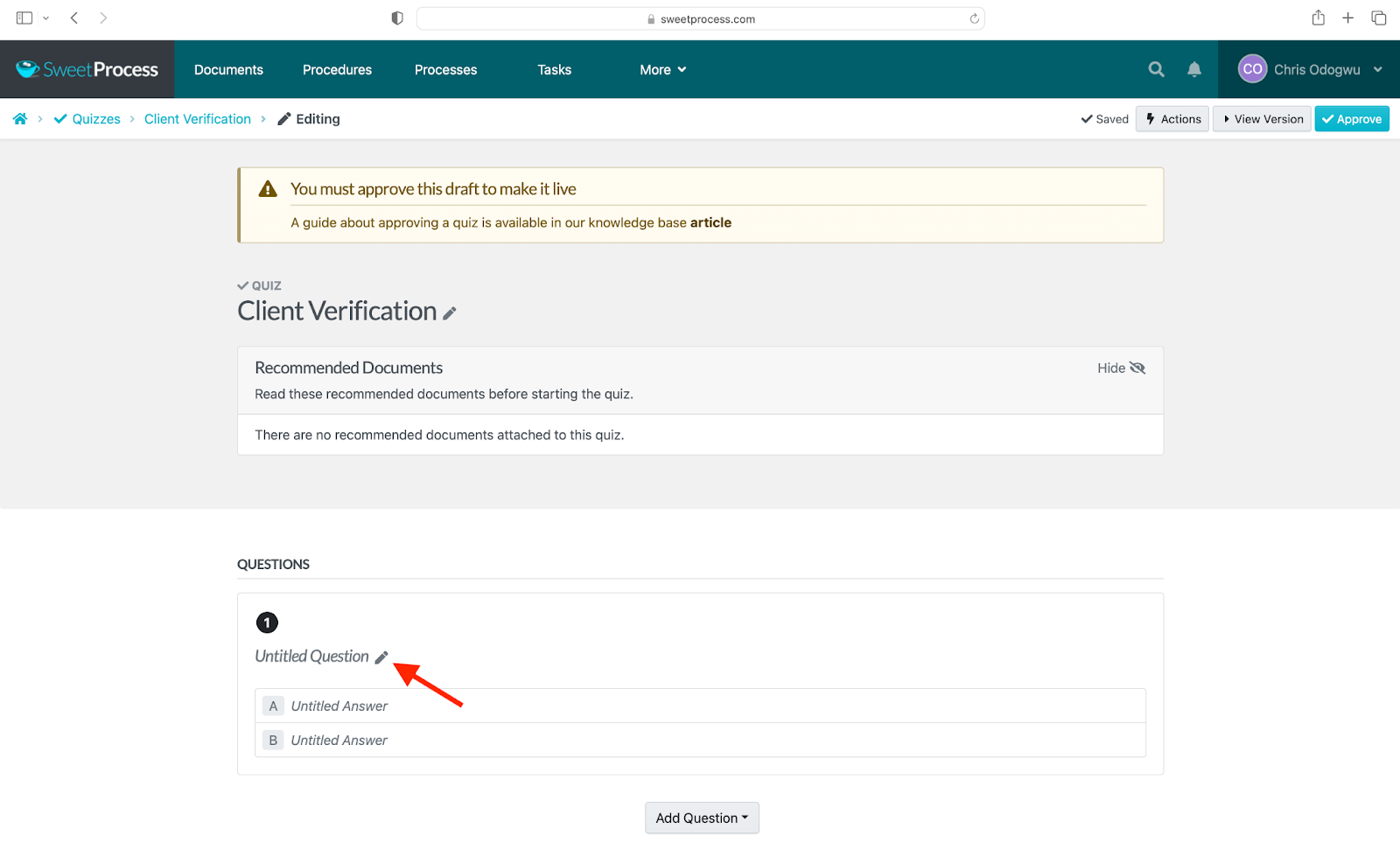

Click “Add Question” and select the question format.

Click the pencil icon to enter the questions and answer options, and click “Finished Editing” to proceed.

Click “Add Question” to add more questions.

Click “Approve” to make the quiz live.

Turn Existing Procedures and Policies Into a Beautiful Knowledge Base

Employee performance depends on their knowledge of assigned tasks. When asked to execute tasks they are not familiar with, employees seek information from those around them, usually more experienced colleagues.

Instead of focusing on their work, these colleagues spend time answering questions. Katie Sullivan, marketing and customer experience director at Preferred Home Services, recalls her team members asking her several questions about how to perform certain tasks. Her work was suffering because she spent a lot of time putting them through. Things changed for the better when the organization created knowledge bases in SweetProcess.

“If people ask me for assistance sometimes, instead of having to take some 40 minutes to walk them through it, I can send them a link to SweetProcess and say, ‘Here’s what you need to go ahead and get this done,’” Katies says. Both she and her team members are more productive in this area. Continuous improvement is more achievable as new policies, procedures, and processes are implemented and accessible to employees.

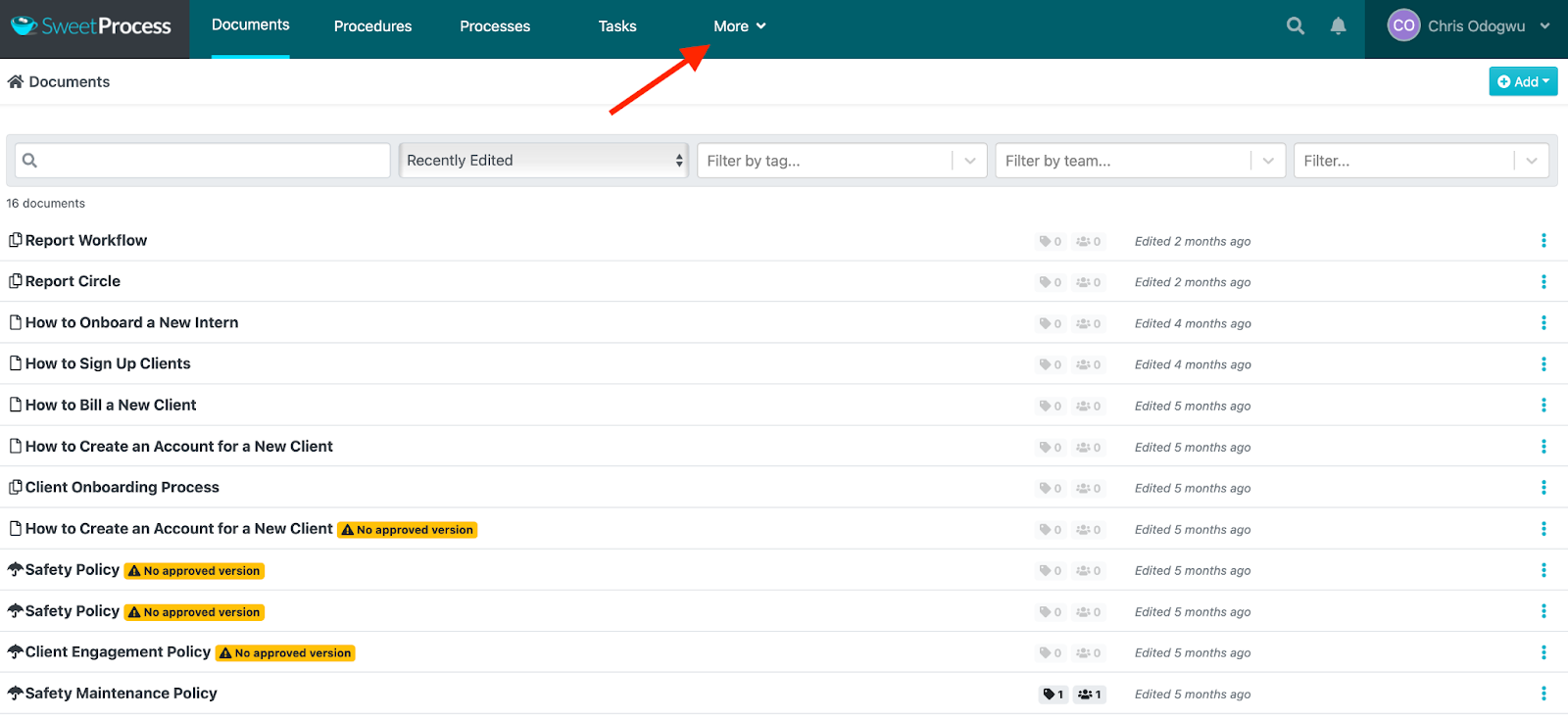

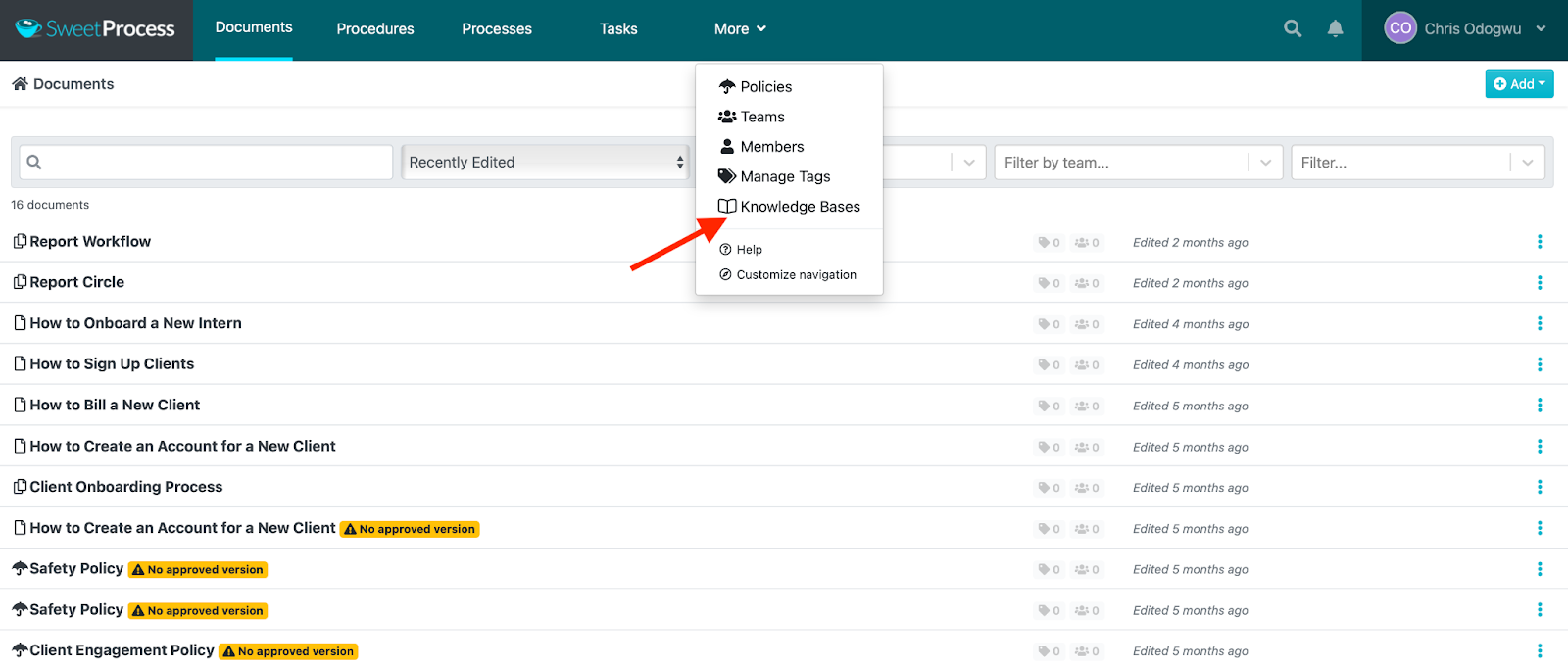

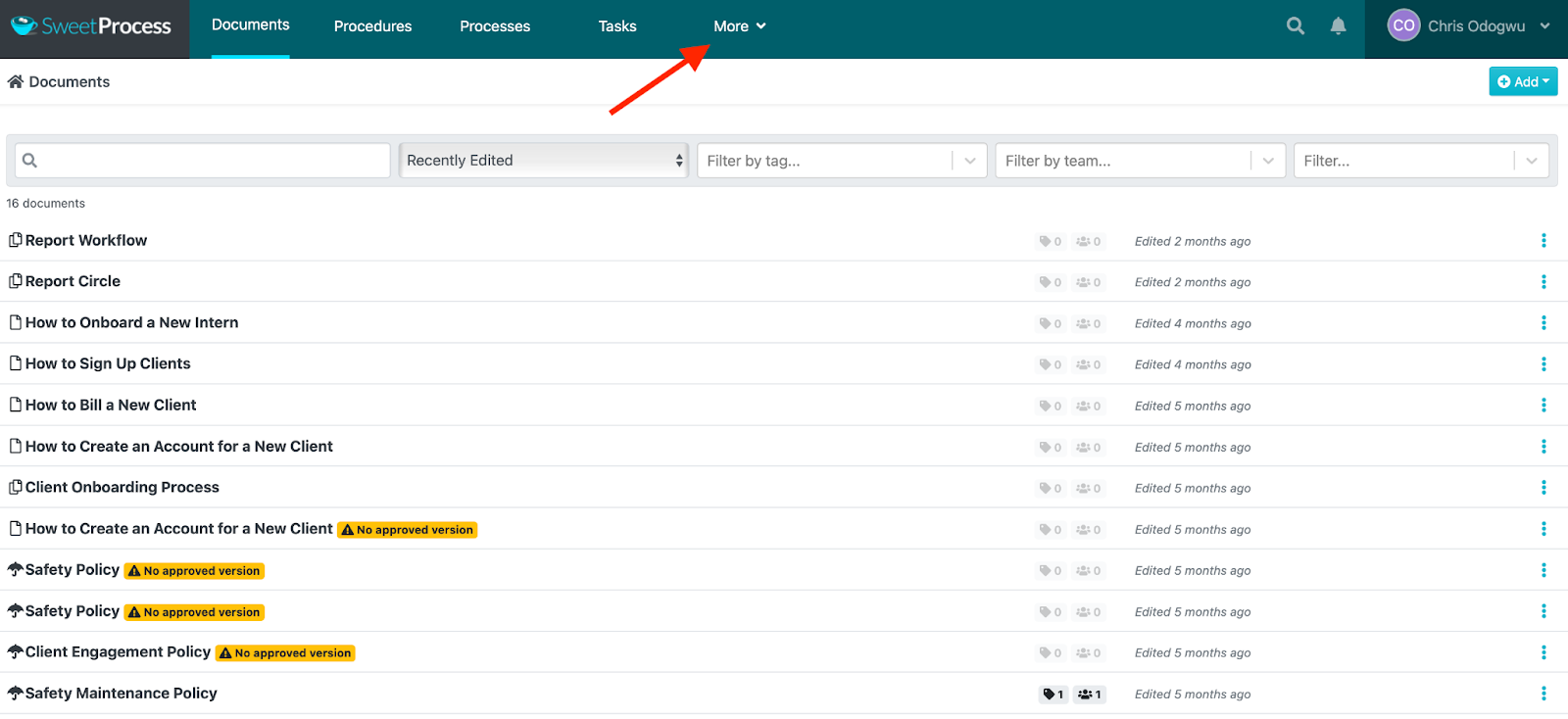

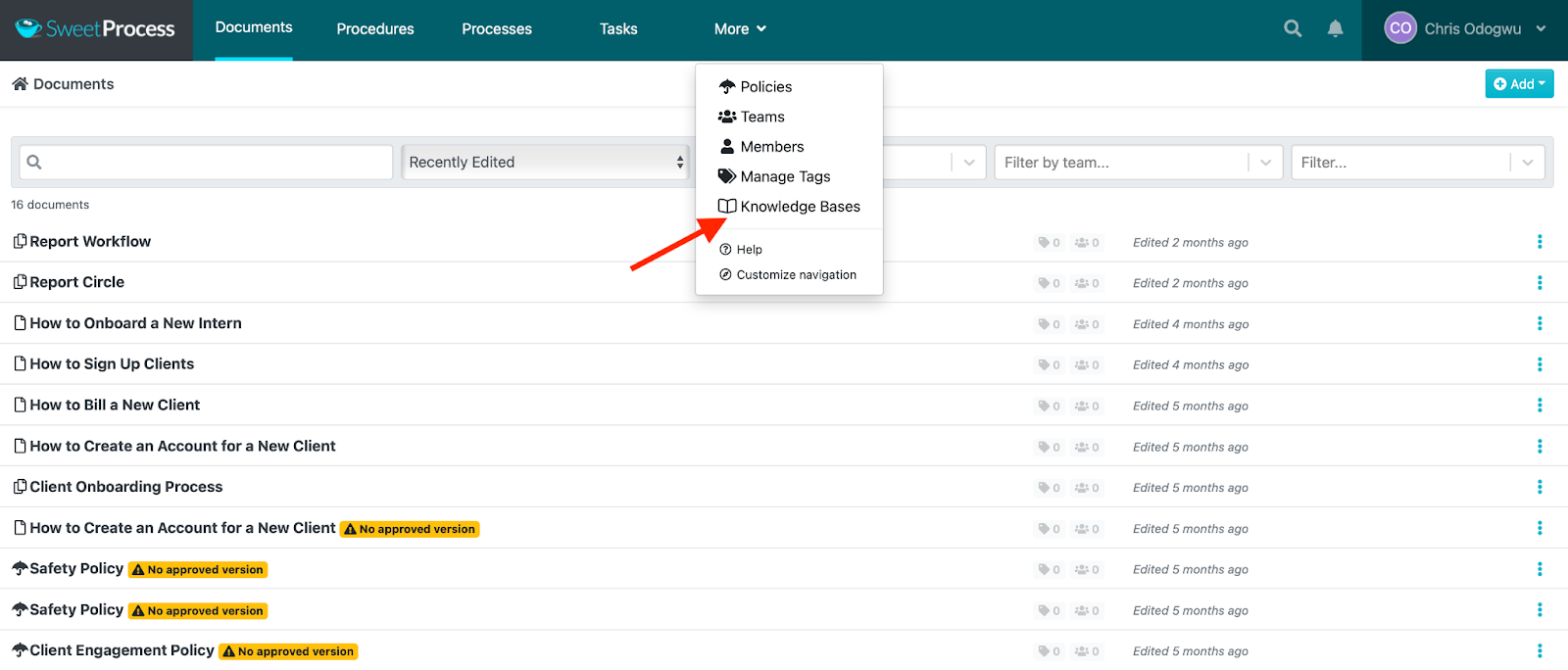

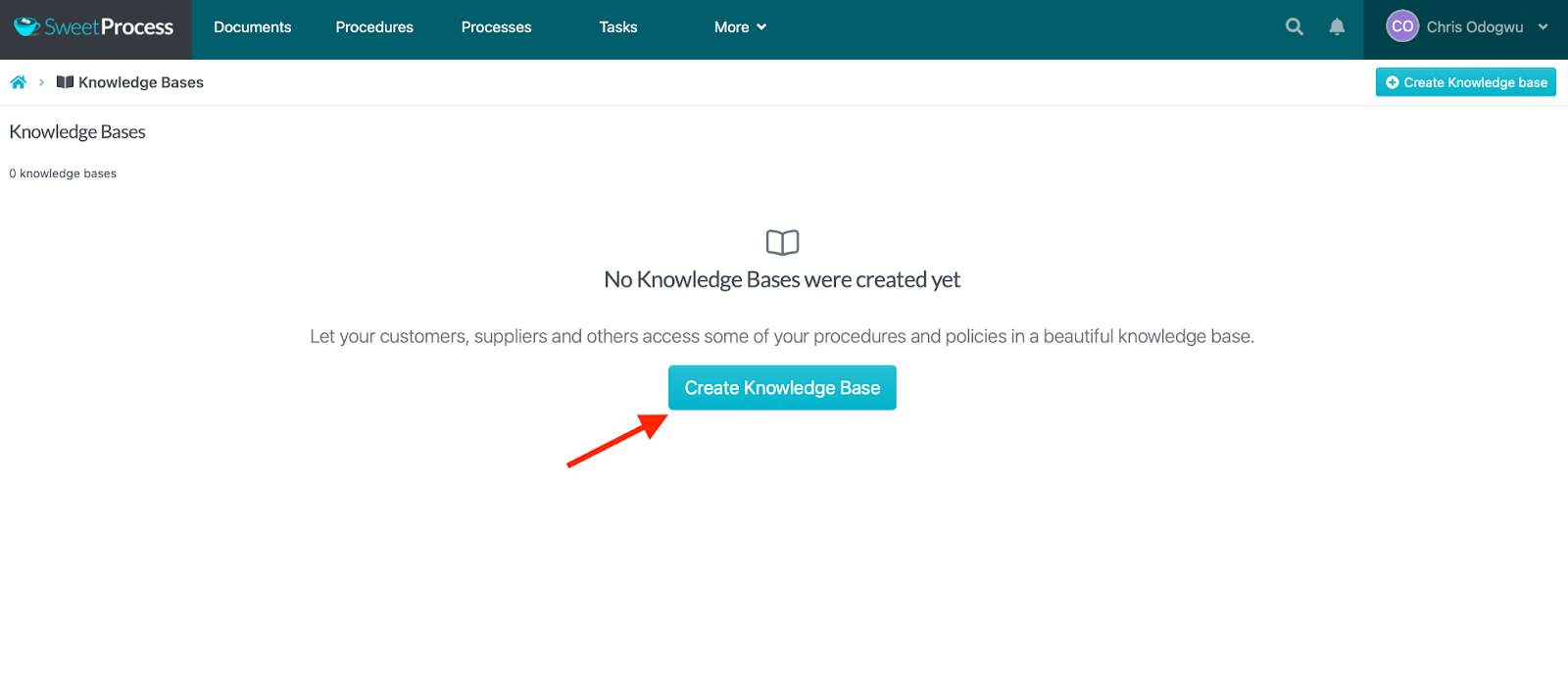

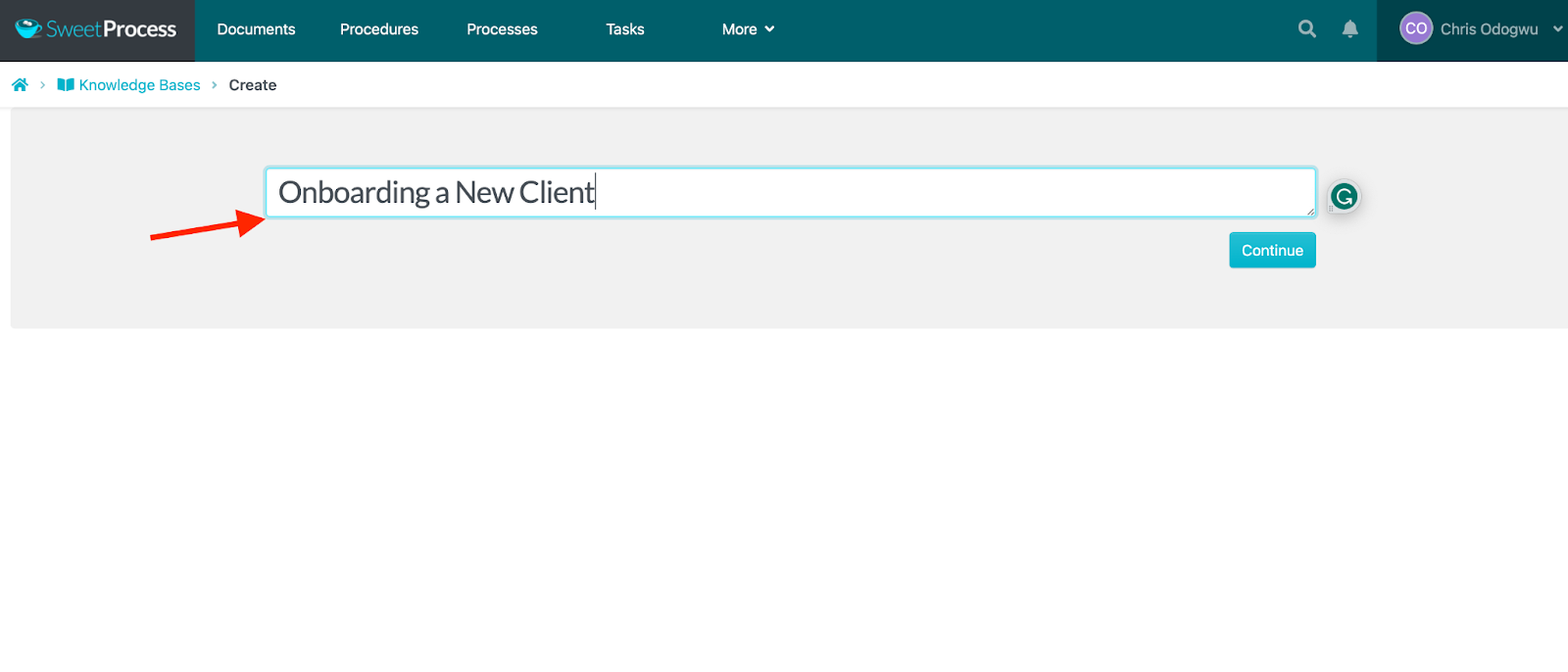

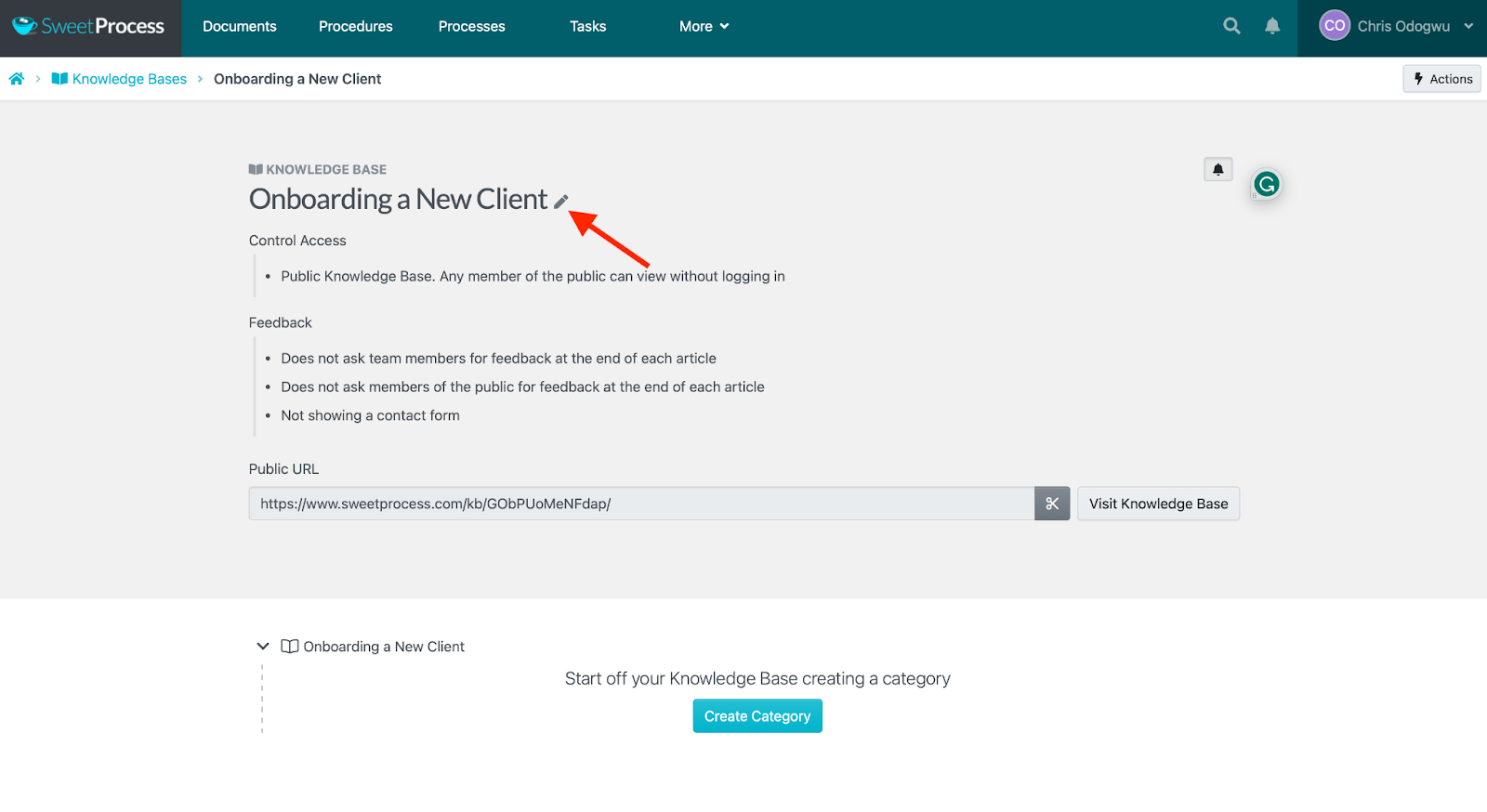

How to Create an Internal Knowledge Base in SweetProcess

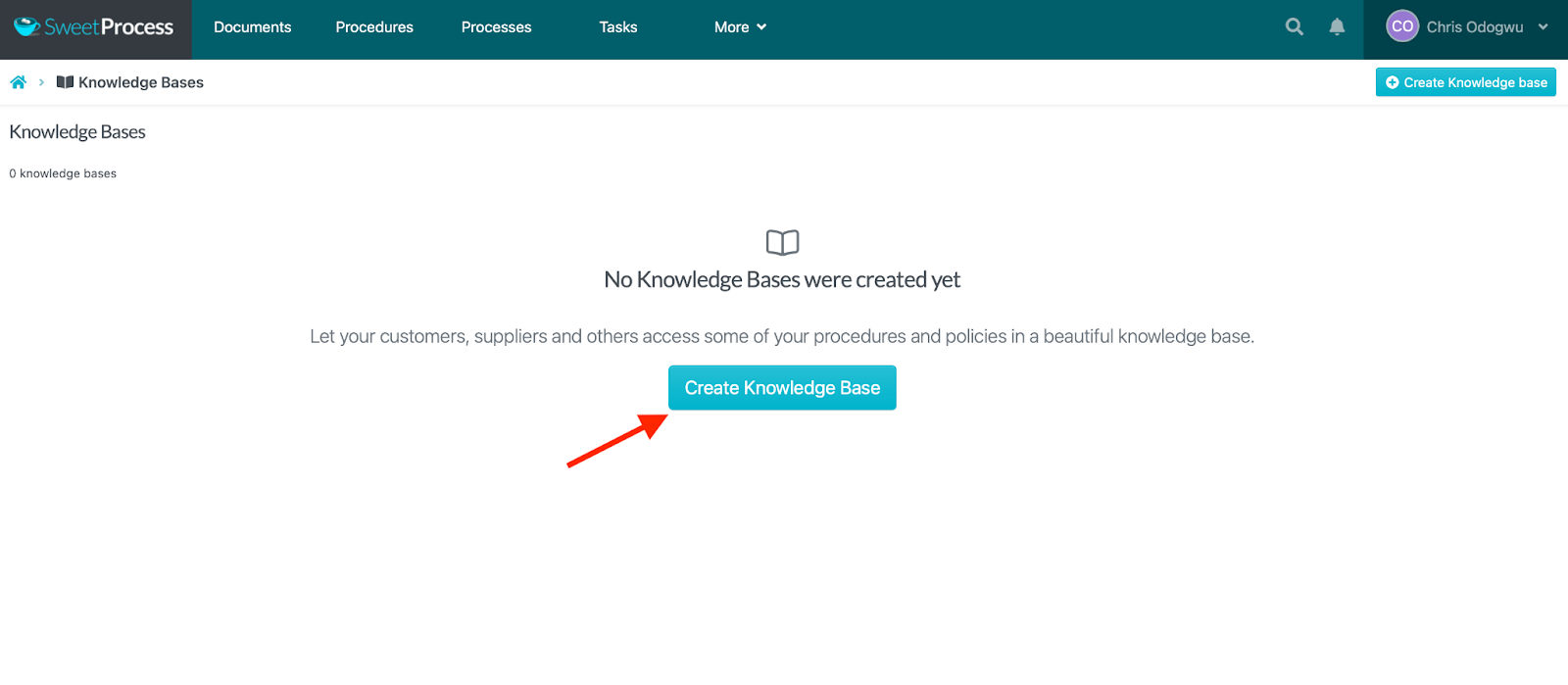

Click “More” and “Knowledge Bases.”

Click “Create Knowledge Base.”

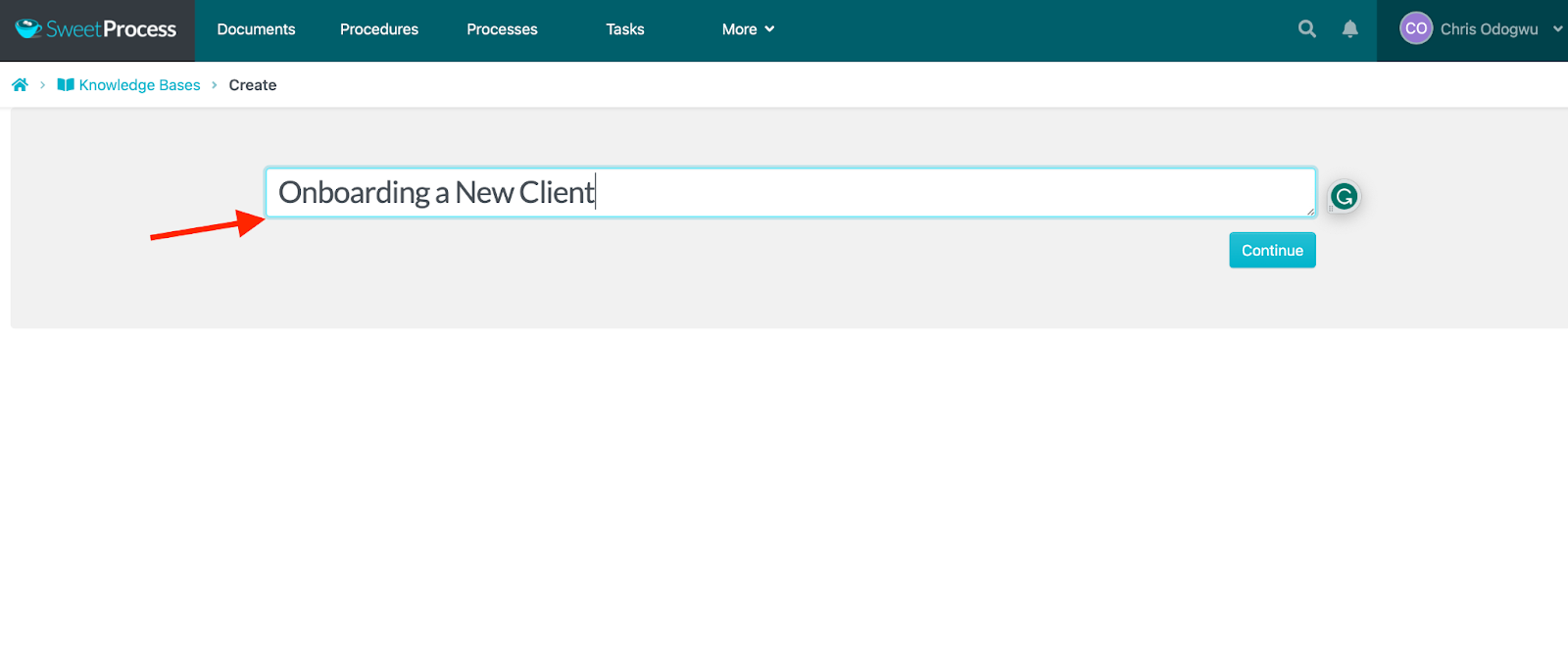

Enter the knowledge base title and click “Continue.”

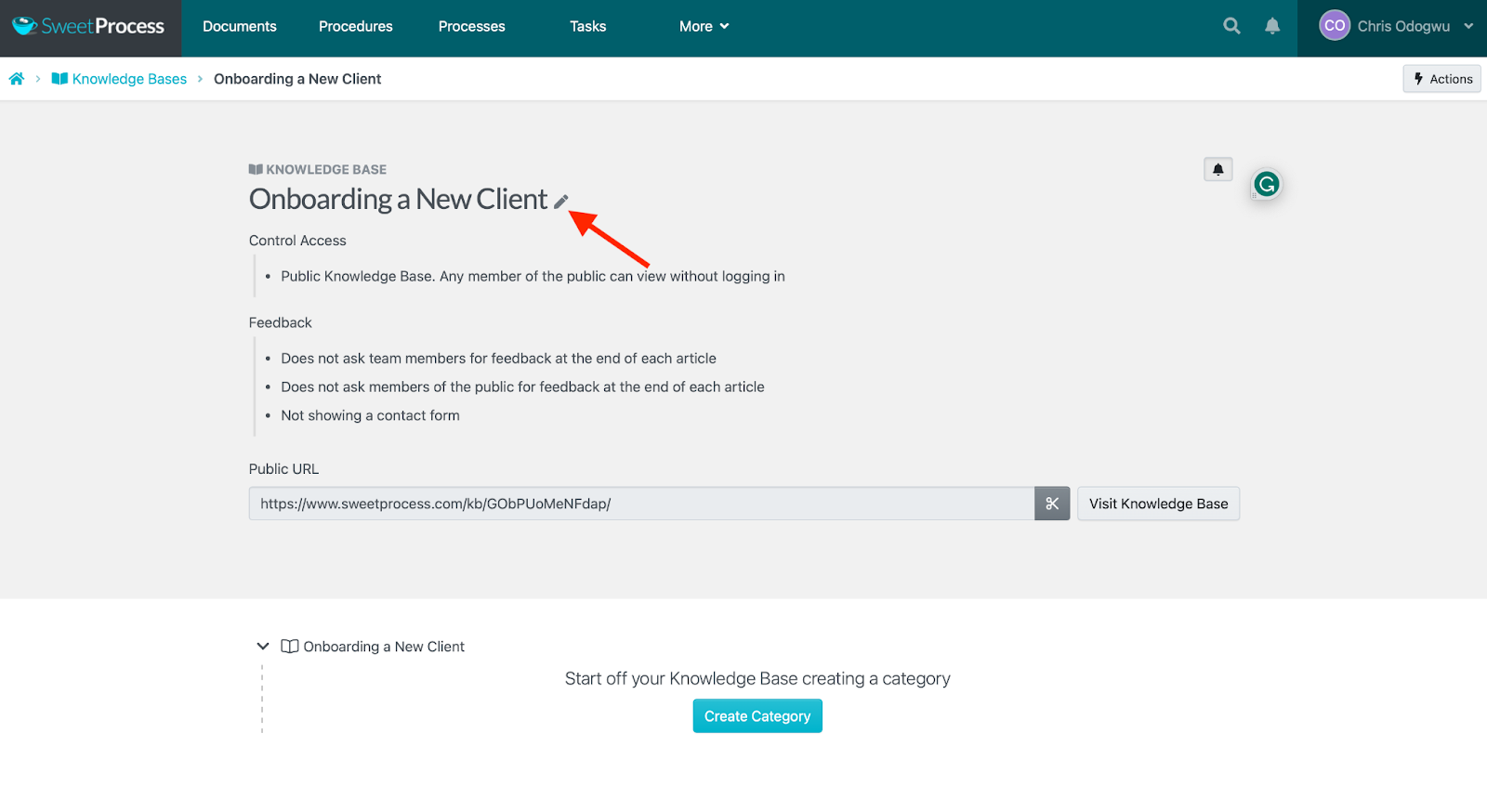

Click the pencil icon beside the title.

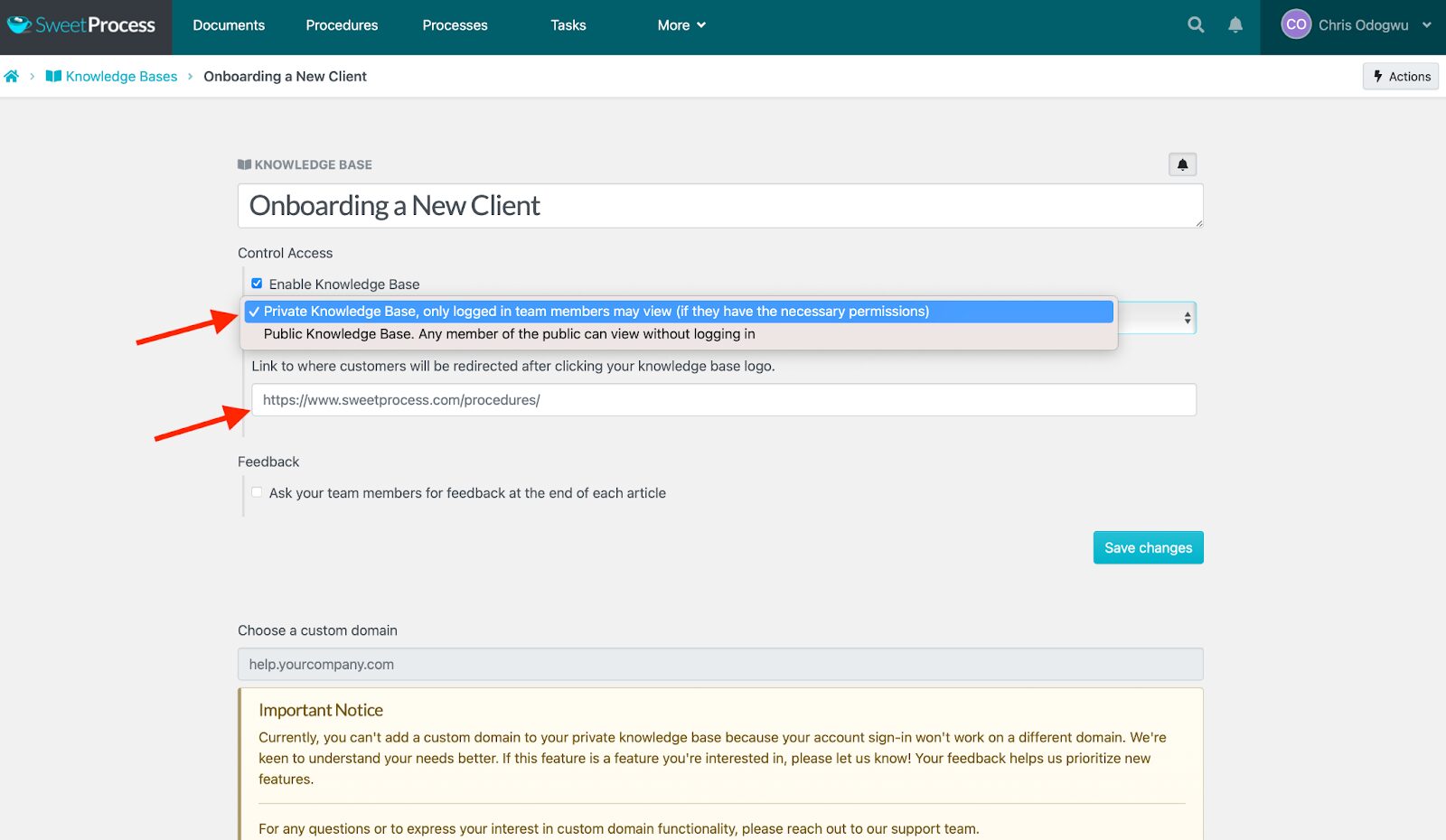

Click the spacebar below “Control Access” and select “Private Knowledge Base, only logged-in team members may view (if they have the necessary permissions).”

Enter the page URL to redirect users when clicking the knowledge base title.

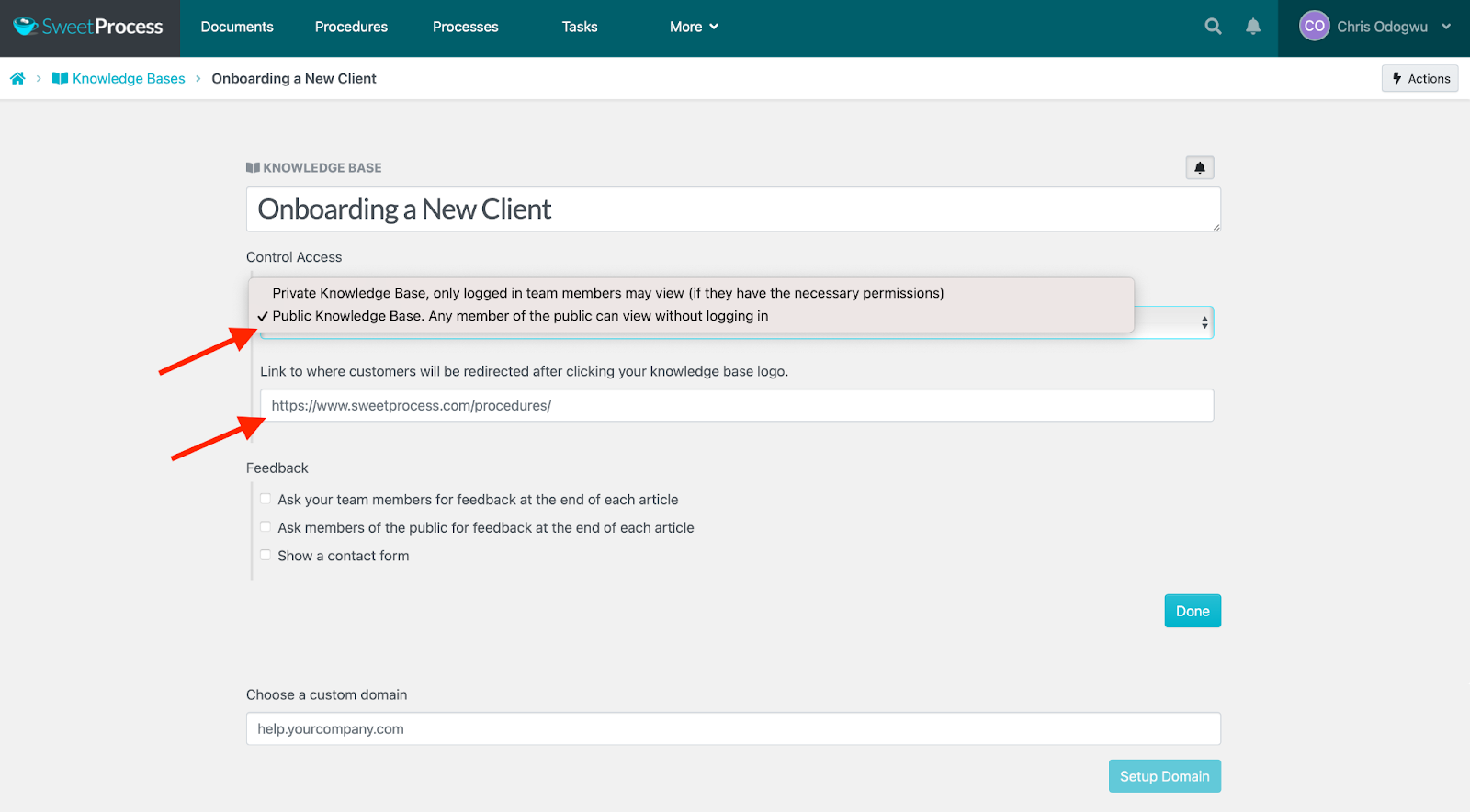

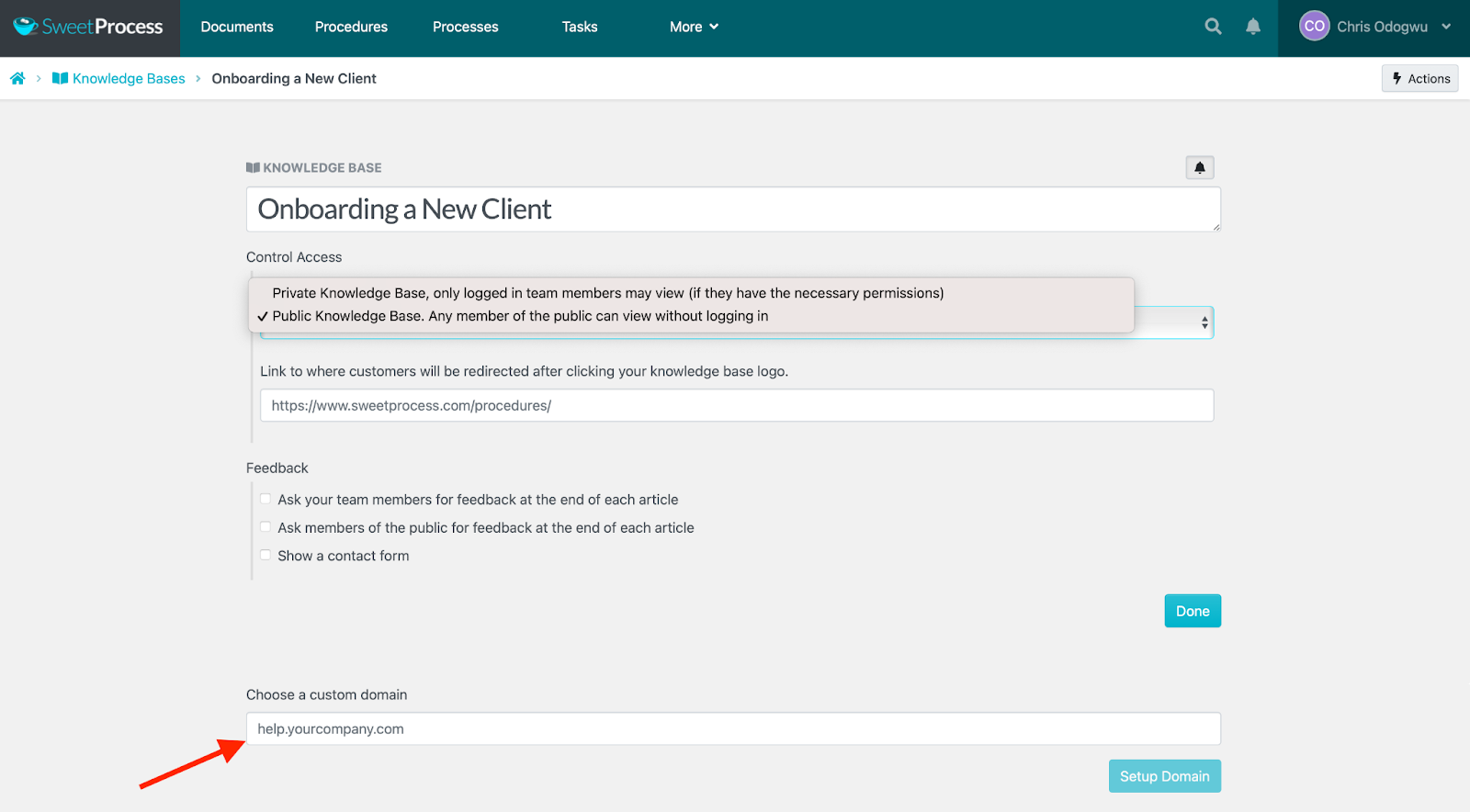

How to Create an External Knowledge Base in SweetProcess

Click “More” and “Knowledge Bases.”

Click “Create Knowledge Base.”

Enter your knowledge base title and click “Continue.”

Click the pencil icon beside the title.

Click the space bar below “Control Access” and select “Public Knowledge Base. Any member of the public can view without logging in.”

Enter the page URL to redirect customers who click the knowledge base title.

You can also redirect users to a custom domain.

Manage Policies, Procedures, and Processes

SweetProcess is flexible in managing policies, procedures, and processes. You can do this after creating these documents in the system.

Open the policy, procedure, or process and click “Actions.”

Select the action you want to perform from the drop-down menu. If you want to assign it as a task, click “Assign as Task.”

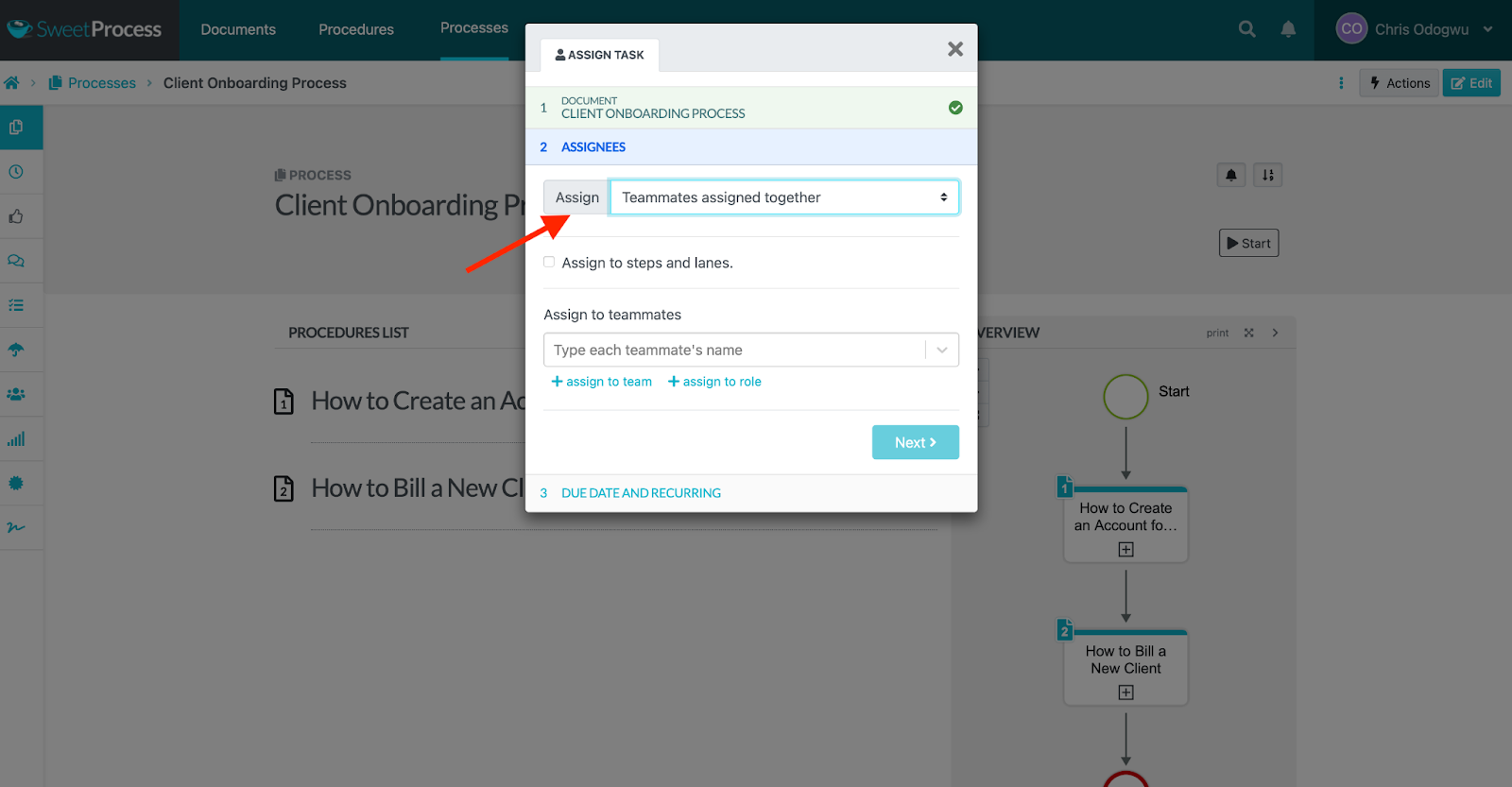

Click “Assign.”

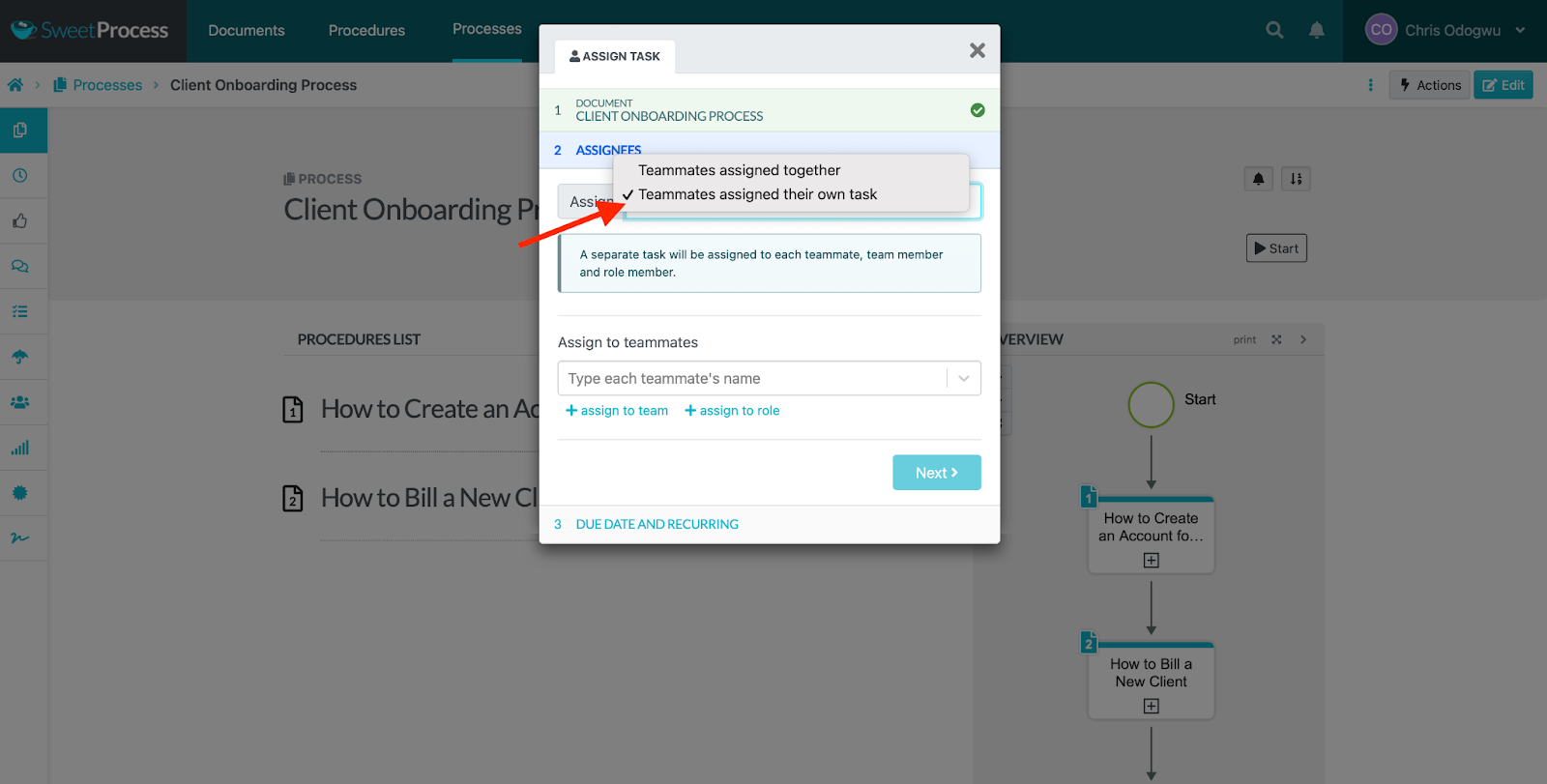

To assign the task to one person, click “Teammates assigned their own task;” to assign it to multiple people, click “Teammates assigned together.”

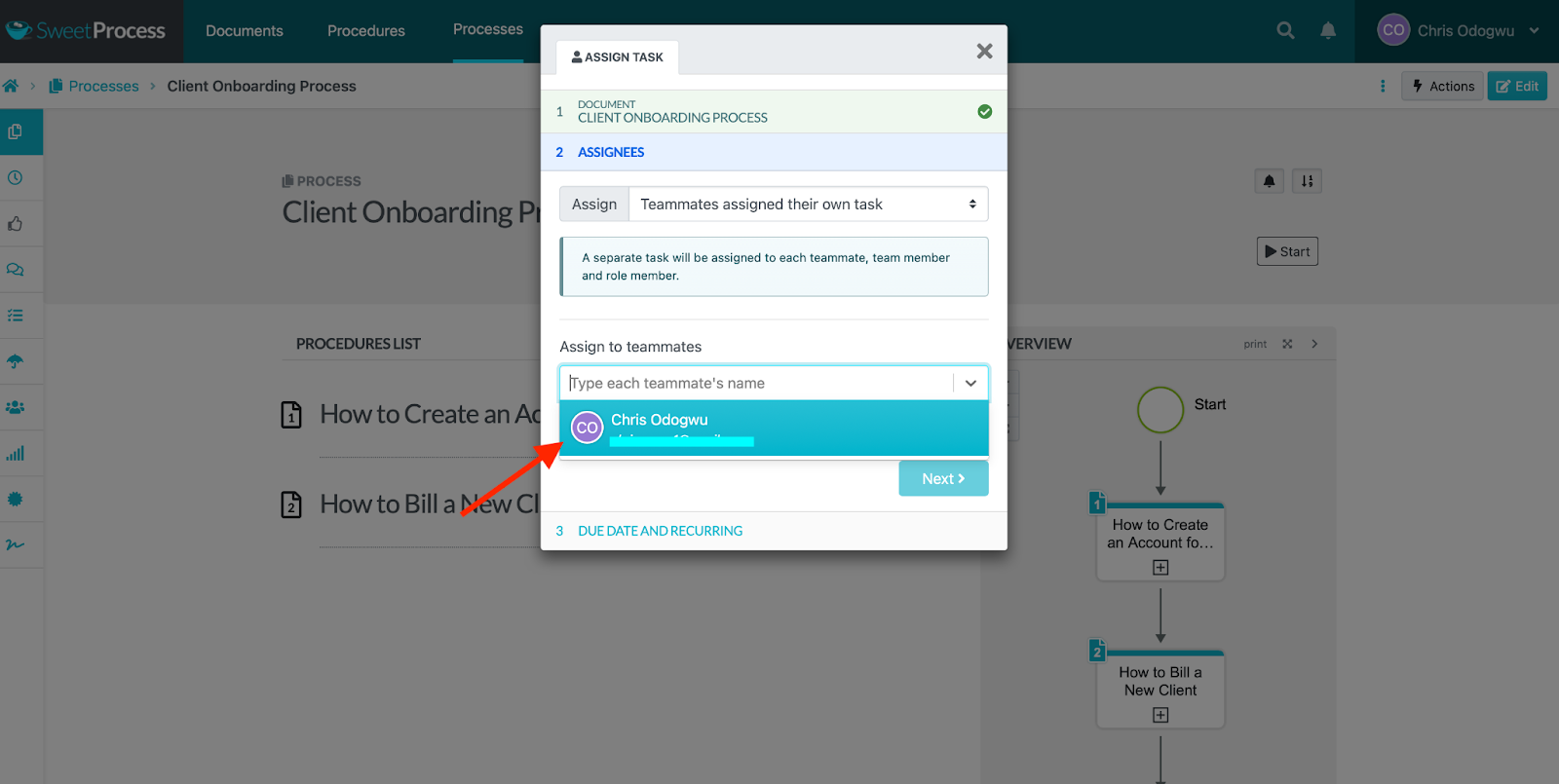

Select the teammate.

Enter the task name, due date, time, and frequency, and click “Assign Task.”

Continuous improvement entails streamlining the various components within an organization’s operations, from standardizing processes to building knowledge bases. SweetProcess’s bespoke features are specifically designed to meet such needs. Amy and Katie may run different businesses, but they had a common need to improve their operations, and SweetProcess helped them achieve that. Whatever the nature of your business, you can improve your current operations by leveraging SweetProcess tools.

7 Continuous Improvement Examples in an Organization

Continuous improvement may be different for different organizations. However, there are established example frameworks that can be used as a guide for peculiar business environments.

Ideation and Think Tanks

An organization’s employee base consists of skilled and talented individuals in their respective areas of specialization. If not encouraged, they may be reluctant to share their expertise beyond their immediate duties. Hold regular ideation and think tank sessions for team members to brainstorm ideas for improvement. Create an agenda for each session to give them an area to focus on.

Information Technology

Effective workflow tools simplify tedious tasks, making employees work faster. Information is at the center of business operations. A lack of it causes tribal knowledge and operational setbacks. You can avoid these by creating a knowledge base of work instructions in SweetProcess. The knowledge bases have access control for confidentiality. Authorized team members can access updated processes, procedures, and policies to perform tasks collaboratively and independently.

Sign up for a 14-day free trial to check it out. No credit card is needed.

Surveys and Polls

Employees may have concerns about work processes but may not express them if not asked. Vital information that could enhance operations could go unnoticed. Conduct surveys and polls to get employees’ honest feedback about current business processes. Ask them about their pain points and how they can be improved.

Cross-Train Employees

The skill set of an organization’s employees impacts its output. Employees with versatile skills offer more value as they can perform tasks outside their primary duties if the need arises. Cross-train employees in multiple roles to prevent setbacks if team members are absent.

Catchball

In the catchball method, the person in charge of a project pitches an idea to the team and allows them to brainstorm. Each participant tries to refine the idea in their own way. The manager moderates the brainstorming session, guiding team members in the right direction.

Stand-Ups

Stand-ups are regular meetings where employees share any challenges, new developments, and progress in their jobs. They are called stand-ups because team members are on their feet during the meeting. The idea is to keep it short by addressing key issues.

Process Optimization

Process optimization in business is about finding ways to get better task results. A small but thoughtful addition could enhance a task. For example, an anonymous survey about current processes among employees may yield better results than an open one because employees can be more honest.

Tools for Continuous Improvement

If two employees are assigned the same tasks—one has digital tools and the other does not—the former is most likely to perform better because the tools give them an advantage by streamlining their work, which is instrumental in continuous improvement. Here are some tools to consider:

Process Mapping Tools

Process mapping tools are used to visualize the processes for executing tasks. People usually discuss and write down work instructions, but no matter how comprehensive they try to be, some details may be lost in translation. Business process mapping minimizes communication barriers by showing processes in action. These tools enable people without design skills to create comprehensive process maps.

A good example of one is SweetProcess. As you create your processes, it automatically generates a map of them. Team members can see the task’s progression, detailing every step. It is also handy for creating organizational charts — showing the various roles and reporting channels in an organization.

SweetProcess offers a 14-day free trial you can explore without entering your credit card details.

Data Analysis Software

Data-driven operations minimize risks and increase business success rates by giving insights into favorable decisions. However, raw data is not very useful and must be analyzed for meaningful interpretations. Data analysis software simplifies complex data by analyzing all data entered into the system. It also reveals blindspots in operations, giving businesses a complete view of their operations.

Project Management Tools

Project management tools are useful in managing the multiple aspects of projects, such as scheduling, assigning, and tracking tasks. Doing all of these manually can be daunting, increasing the chances of things falling through the cracks. A good project management tool allows you to automate some of the processes to your needs. This is especially useful when improving operations to a certain standard. The workflow moves uninterrupted with minimal human input, removing setbacks from employees being preoccupied with other tasks.

Collaboration Platforms

Collaborative platforms facilitate remote teamwork. These are essential in the workplace as remote work gains more momentum. Collaboration can be challenging without a tool for sharing information and engaging with one another. A centralized system for creating and accessing documents, assigning tasks, and engaging with projects drives continuous improvements by availing teams of relevant resources.

Continuous Improvement Metrics to Track Your Progress

Focusing on important elements is crucial for continuous improvement. Driven by a zeal to achieve maximum results, businesses might commit to too many factors, including irrelevant ones. Streamlining your attention to what matters is an advantage.

Safety

No amount of growth or profit is worth endangering your employees, customers, and society at large. This also includes the legal and compliance implications of your improvement efforts. If the new processes pose risks, measures must be taken to minimize them to an insignificant level.

Cost

Continuous business improvement inevitably incurs costs. However, expenditures should be done meticulously to prevent unnecessary spending. Prioritizing value over high costs allows businesses to explore various alternatives for usefulness instead of choosing the most expensive options under the illusion that they are best.

Quality Metrics

The quality of a product or service is known by its use. Having implemented new improvement measures, you can see the difference almost immediately if there is any. The more difficult task is maintaining the same quality across the operations chain. Establish continuous quality improvement measures for long-term success.

Time

Executing processes faster creates room for more work. Although shortening the delivery time should be the goal, it should not be at the expense of quality. Do not mark a process as successful because it is faster without examining the output quality. Both metrics must be proportional to be favorable.

Return on Investment (ROI)

Introducing new processes impacts revenue generation either positively or negatively. Things could easily go south without thorough thinking and planning. Improvement decisions should be made by examining the profit potential of the improvement initiative. There may be no guarantees, but loss can be minimized by working with data.

Key Performance Indicators (KPIs)

Continuous improvement is sustainable with key performance indicators (KPIs). These are tangible elements within the improvement. KPIs are SMART by being specific, measurable, achievable, relevant, and timely. Examples include profit, production volume, customer satisfaction levels, etc.

Employee Feedback and Surveys

Employees are the first viable source for measuring the effectiveness of new processes. Cultivating a healthy employee engagement culture before implementing changes enables team members to engage well enough to give honest and useful feedback. This can be done easily with SweetProcess. It offers feedback and survey templates that you can edit to your taste. Employees receive a notification about the survey and use a secure link to share their feedback.

Customer Satisfaction

Customer satisfaction levels are good indicators of improvement efforts. As end users of a product or service, customers are happy to express their satisfaction or dissatisfaction with new measures. Proactively get their input using surveys and other feedback mediums like customer satisfaction score (CSAT) and net promoter score (NPS) to collect scorable feedback.

Enhance Your Continuous Improvement Efforts With SweetProcess

Customers’ expectations are higher, with many options at their disposal. Thirty-three percent of them may stop patronizing a business after one bad experience, and 17% do not mind paying more for a better service.

Would you rather improve your services and earn more or lose your customers? SweetProcess has helped many businesses to not only scale but also continuously improve their services.

Sign up for a 14-day free trial to check it out yourself. A credit card is not required.