Last Updated on March 8, 2025 by Owen McGab Enaohwo

![What Is Lean Six Sigma? [Benefits, Principles, Techniques, and Examples]](https://www.sweetprocess.com/wp-content/uploads/2024/09/lean-six-sigma.png)

Many organizations today struggle with balancing efficiency with rising costs and are unable to answer the recurring question: “What’s the best way to reduce costs while meeting customers’ demands?” Lean Six Sigma is the answer!

Lean Six Sigma methodology helps organizations reduce costs by eliminating waste from production or processes and reducing defects or variations in products or services. Its principles are not just a business fad but a tried-and-tested approach to improving efficiency.

Businesses that have adopted these principles have reported higher cost savings and major improvements in product and service quality.

A McKinsey report highlighted how a global bank reduced costs by 15% to 20% across more than 2,000 branches using this approach in their business process improvements.

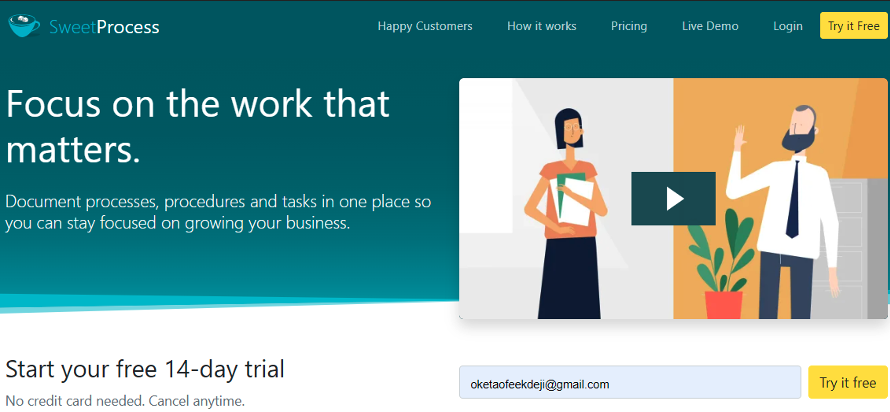

Ready to transform your operations? SweetProcess is here to help. As a robust workflow management platform, SweetProcess streamlines your processes, documents SOPs, and enhances collaboration across your team. To start your journey toward operational excellence, sign up now for our 14-day free trial—no credit card required.

Table of Contents

Benefits of Using Lean Six Sigma in Your Business

7 Key Principles of Lean Six Sigma

How to Ensure Consistency in Your Company’s Processes Using SweetProcess

Lean Six Sigma Techniques and Tools

The Five Phases of Lean Six Sigma

Examples of Implementing Lean Six Sigma

Six Sigma vs. Lean Six Sigma: Differences and Similarities

Lean Six Sigma Belts and What They Mean for Your Business

Start Your Company’s Lean Six Sigma Journey With SweetProcess

What Is Lean Six Sigma?

Lean Six Sigma is a smart blend of two methodologies: lean and Six Sigma. Toyota developed the lean technique in the 1940s to streamline its manufacturing process and boost productivity. The lean methodology is centered on streamlining operations and optimizing workflows to remove non-value-adding activities from the manufacturing process. It involves reducing and eliminating eight types of waste, known as DOWNTIME: defects (overproduction), waiting, non-utilized talents, transportation, inventories, motion, and extra processing.

On the other hand, a Motorola Corporation engineer invented Six Sigma in the 1980s, drawing inspiration from the Japanese Kaizen concept. This method eliminates errors and waste in production processes.

This method served as the basis for Lean Six Sigma, which blends Six Sigma’s data-driven problem-solving methodologies with Lean’s core values. Combined, these techniques offer a thorough framework that helps businesses improve their workflows, eliminate waste, and offer outstanding value to customers.

Establishing clear objectives and knowing what your consumers value can help you lay a strong basis for implementing lean Six Sigma in your own company. Next, identify and analyze your current processes to uncover areas of waste and inefficiency. With the right training and lean Six Sigma tools, you can make data-driven improvements that will significantly impact your bottom line. It follows a structured approach known as DMAIC: define, measure, analyze, improve, and control.

Benefits of Using Lean Six Sigma in Your Business

Putting Lean Six Sigma into practice in your organization has several advantages, summarized in six key benefits below.

Simplify Your Business Processes

A Lean Six Sigma methodology will help your organization reduce waste and identify non-value-added tasks. This can simplify processes and eliminate unnecessary steps that don’t bring value.

By applying lean process improvement, businesses can refine workflows, making them more efficient and easier to manage. It’s like decluttering your workspace so that only the essentials remain, ensuring smoother operations and improved productivity.

Make Fewer Errors and Mistakes

When it comes to the lean Six Sigma process, the first step is to establish the desired level of quality that meets customer expectations. Prioritize continuous improvement efforts to address the problems that impact business success most. This results in changes that fix real problems and bring them to a level acceptable to real customers, addressing the errors and mistakes that mean the most.

Ensures Predictable Performance From Employees

This methodology sets clear standards and procedures, which means employees know exactly what’s expected of them. It creates simple processes with less variance that are easier to oversee and manage, resulting in more predictability. Predictable cycle times, quality output, and costs contribute to improved customer service, fewer complaints, and more revenues.

Satisfy Your Customers

Lean Six Sigma principles use tools and techniques to create a customer-focused operation with customer experience on the front burner. By enhancing processes and effectively overseeing quality, organizations can achieve superior products and services. As a result, you will be able to provide exceptional customer satisfaction and encourage repeat sales.

Drives More Sales and Revenue

The lean Six Sigma methodology also helps businesses increase the speed and effectiveness of their lead generation efforts by eliminating waste and reducing variability in lead generation processes. This means that more leads are generated in a shorter period and with fewer resources, which will lead to increased revenue and profitability. It helps create a ripple effect of satisfaction that spreads, increasing sales and boosting revenue.

Reduces Operational Costs

By eliminating non-value-adding activities, automating repetitive tasks, and enhancing process and resource efficiency, businesses can significantly reduce operational costs and improve service levels. When you streamline your operations, you save time and resources and cut down on expenses. Implementing lean Six Sigma principles within your organization is a great approach to operational excellence through efficiency.

7 Key Principles of Lean Six Sigma

In the fast-paced and globalized world of business today, competition is strong. As such, organizations need to keep an edge in the marketplace, which drives businesses to explore new lean management techniques. The seven key lean Six Sigma principles are guidelines that help organizations improve their business processes.

Focus on the Customer

The principal objective of every business is to offer a product or service that its customers will pay for. Try to imagine yourself as your client and determine whether your offering lives up to their expectations. Identify your ideal customer profile and conduct surveys or hold focus groups to understand their needs, expectations, and pain points.

Align your processes to deliver value that directly addresses these needs. Highly successful businesses offer extra value according to their customers’ needs. Customer-centricity is another name for this concept.

Address a Real-World Problem

Don’t get mired down in hypothetical problems. Focus on identifying recurring issues that generate frustration for customers or hurdles for staff members. Brainstorm together to find the areas that require the greatest improvements—aim for the problems that deliver the most punch. Prioritize problems with the most impact. Collect data that suggests where your specific problem area sits and concentrate on refining that area.

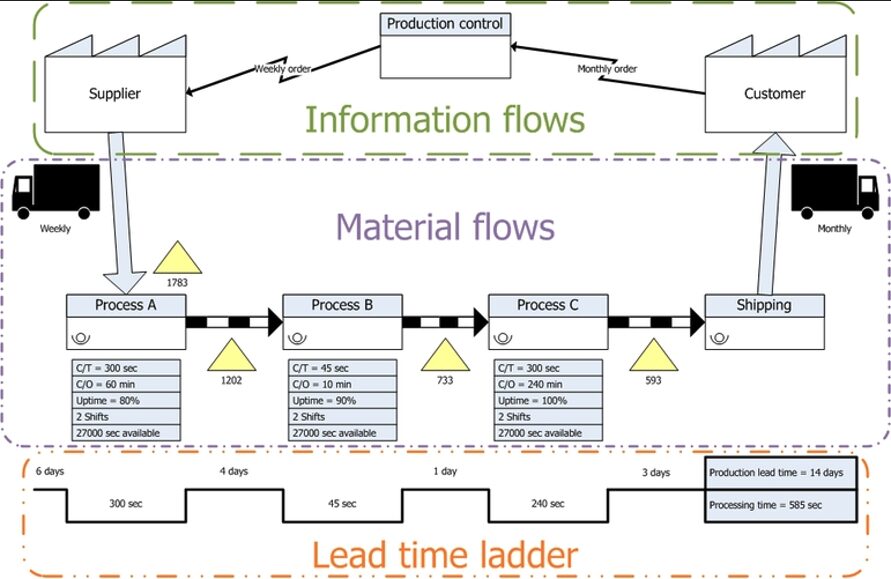

Measure the Value Stream

Consider the entire process—from when a consumer places an order to when they receive the finished product—as a journey. Lean Six Sigma encourages mapping the journey and identifying each stop along the route. Track the time for each step, look for bottlenecks, and determine potential problem spots.

To build a value stream, all necessary persons, protocols, data, and inventory are provided in a flowchart. Value stream mapping can be done on a whiteboard using Post-its with extra information or flowchart software, as seen below.

Base Your Analysis on Data

Lean Six Sigma is a data-driven methodology that supports an organized, data-driven approach to process improvement inside an organization. It entails identifying, analyzing, and implementing changes rigorously and systematically by adhering to a specific methodology such as DMAIC.

Get Rid of Waste

The idea of waste removal initially appeared in the Toyota Production System. In the context of lean, waste is a “non-value-added activity,” and we are reducing that timeline by eliminating non-value-added waste. Lean Six Sigma aids in locating these inefficient processes. Eliminating inefficient operations may help companies make the most of their resources, increase profitability, and significantly improve operational efficiency.

Involve Stakeholders

Put together a team with members from each department affected by the problem. Their many viewpoints are invaluable. It underscores the relevance of stakeholders in the success of any project and the value of collecting and analyzing data to inform stakeholders about the workflow’s efficiency or inefficiency.

Ensure a Flexible and Responsive Ecosystem

Promoting a flexible and responsive ecosystem is the last principle. Change is inevitable. Once you have implemented improvements, do not just sit back and relax. Continually track and quantify the effectiveness of the new process. As required, be ready to modify and adapt. Remember, the goal is to continuously improve, so keep your finger on the pulse of your customer’s experience.

How to Ensure Consistency in Your Company’s Processes Using SweetProcess

Looking to deliver consistent, high-quality results in your business? SweetProcess provides a user-friendly platform that simplifies Lean Six Sigma by streamlining process documentation, task management, and knowledge management.

Let’s find out how SweetProcess helps you to apply Lean Six Sigma principles for greater efficiency and success.

Avoid Time Wastage in Answering Repetitive Questions by Creating a Knowledge Base

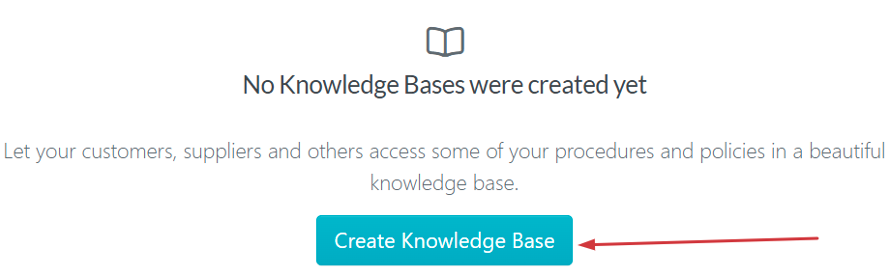

SweetProcess’s knowledge base feature allows you to create a searchable library of articles, FAQs, and tutorials. To create a knowledge base for your business with SweetProcess, follow the steps below:

- Visit sweetprocess.com and sign up to enjoy a no-credit-card, 14-day free trial sign-up.

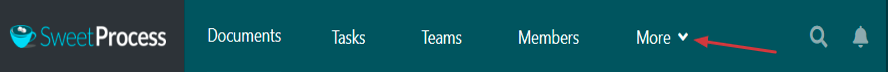

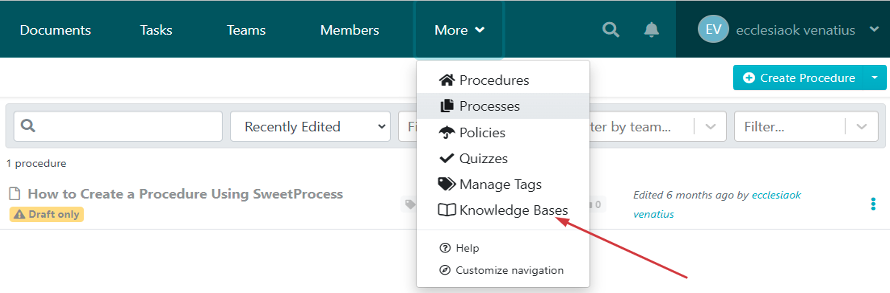

2. Next, click on the “More” dashboard link to reveal a drop-down menu.

3. On the dropdown menu, click on the “Knowledge Bases” button.

4. Click on the “Create Knowledge Base” button.

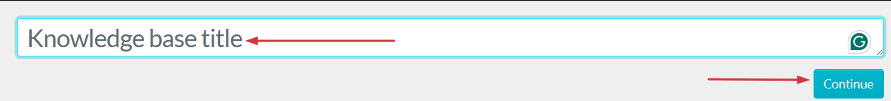

4. Enter the title of your knowledge base and click the “Continue” button.

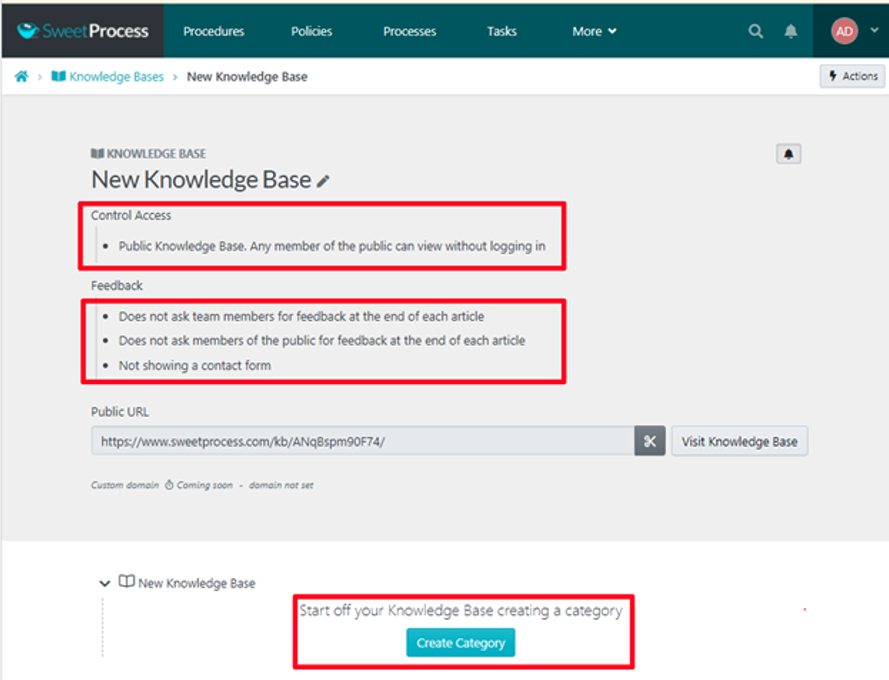

5. Here, you are presented with the default options for your knowledge base.

The SweetProcess knowledge management system organizes everything in one place, and it takes a few minutes to set up your knowledge base with your preferred options, including contact form, access control, and categories.

Case Study 1: pLink Leadership: Empowering Employees Creating a Knowledge Base With SweetProcess.

As a company that is passionate about helping businesses accelerate their growth, pLink needed one thing: an effective tool to document and streamline their operations.

Solution: Using SweetProcess, pLink Leadership experienced effective process documentation and update, seamless employee onboarding and training with an accessible central knowledge base.

Results: Streamlined business operations with the right tools and empowered workforce. Clear guidelines boosted employee confidence and reduced errors.

Reduce Error and Rework by Creating SOPs

Standard operating procedures (SOPs) are the cornerstone of consistent and error-free execution. It comprises a series of step-by-step instructions crafted by a business to help employees efficiently carry out complex routine operations.

SOPs are crucial for reducing errors and minimizing rework, leading to smoother workflows and enhanced productivity. SweetProcess makes creating and maintaining SOPs a breeze. Here’s how:

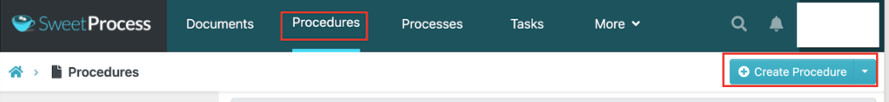

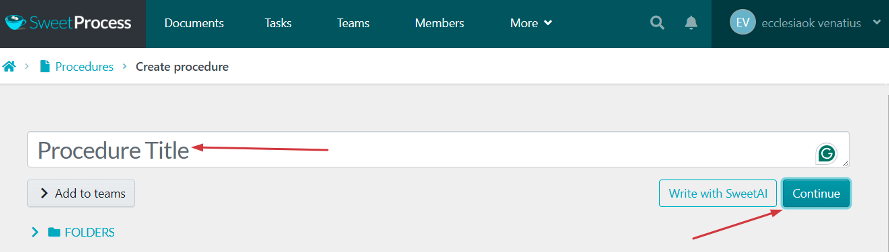

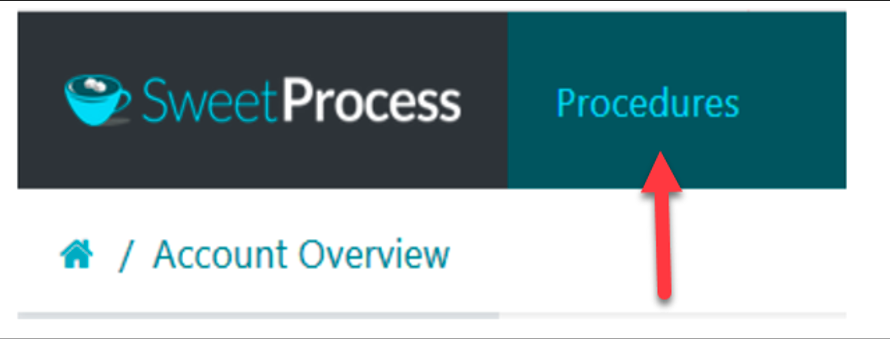

1. Sign up and log in to your SweetProcess dashboard and select the “Procedures” tab on the main dashboard.

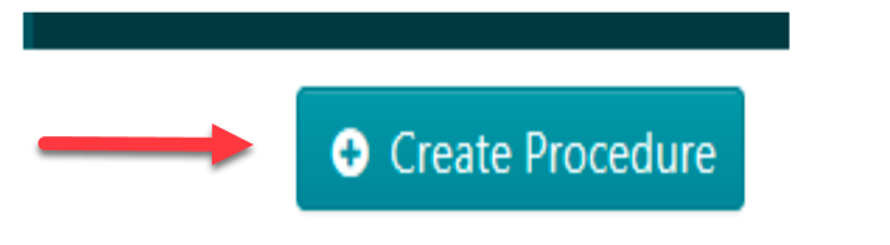

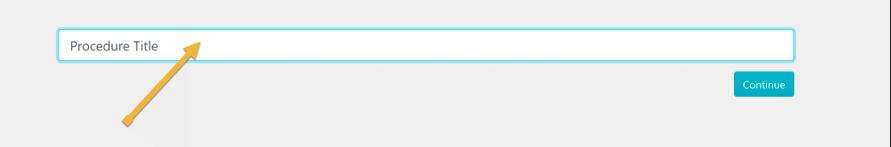

2. Click “Create Procedure” on the next tab and add a procedure title.

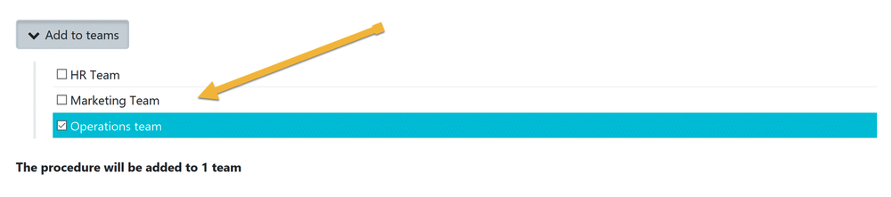

3. Here, you can assign the procedure to specific teams by selecting an option, adding details to your procedure, and assigning them to specific teams.

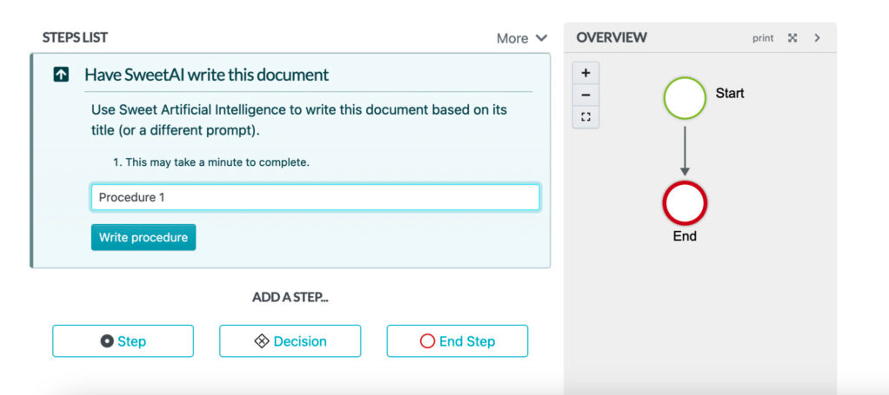

In the next tab, you can add details about your procedure. SweetProcess also offers SweetAI, an AI tool that automatically writes SOPs for you. Simply enter the title, and the document will be generated in minutes.

Case Study 2: All Residential Real Estate Streamlines Operations With SweetProcess

All Residential Real Estate faced many problems from ineffective documentation, which held employees back with no clear instructions on how to execute tasks. The organization had paper-based checklists, but the checklists did not explain how to get things done.

Perry Beebe, managing director, said, “They worked, but business processes changed, and it was difficult to keep those checklists up to date. A checklist only provides a small amount of information. On a single line, it will say ‘Do X,’ and then you tick it off.”

Solution: SweetProcess brought about efficient documentation, consistency in operations, and seamless employee onboarding and training.

Results: SweetProcess provided a clear, organized knowledge base, eliminating reliance on individual expertise. With onboarding and training, new hires adapted quickly with easy access to video-enhanced procedures. Standardized processes ensured uniform outcomes, enhancing overall efficiency.

Perry’s advice? “If you’re working in a procedural-based business, look at SweetProcess. Have a look at the procedures and policies within SweetProcess and see how you could create those sorts of systems in SweetProcess.”

Ready to transform your business operations? Sign up for a 14-day free trial of SweetProcess—no credit card required.

Document and Eliminate Unnecessary Steps by Creating Processes and Procedures

Imagine a business where everyone operates with laser-focus precision, executing tasks seamlessly and efficiently. SweetProcess goes beyond simple document creation. It’s a comprehensive platform designed to transform your existing workflows into streamlined, value-driven processes. To create procedures and processes on SweetProcess, proceed to your dashboard and:

1. Click on the “Procedures” tab.

2. Then click on the “Create Procedure” button on the top right side of the page.

3. Create a title for your procedure.

4. Add the procedure to a team/teams.

Reduce Delays and Misunderstandings by Leveraging Collaboration Tools

To work with team members in SweetProcess, you need to create your team and add it to the process, procedure, and policies to enable collaboration. Next, log in to your SweetProcess account. While viewing the process, procedure, or policy you want to collaborate with your team, you’ll find all the collaboration functionality buttons to the left of the screen.

Lean Six Sigma Techniques and Tools

Here is how you can apply its techniques and tools to streamline your processes and foster a culture of continuous improvement.

Kanban

The Kanban technique of visual workflow management lets you monitor your activities and projects using cards and boards. Before implementing Kanban, start by defining the stages of your current workflow on a board. Next, utilize cards to represent tasks, moving them across the board as they complete each phase.

This visibility allows for tracking in real time and helps identify bottlenecks. At this point, SweetProcess helps you organize activities, track progress, visualize your workflow, and identify bottlenecks.

Kaizen (Continuous Improvement)

Kaizen is a steady, small-step improvement technique. It involves creating an atmosphere in which employees of all ranks actively participate in making suggestions for and carrying out process improvements within the organization.

SweetProcess can be utilized to document all improvement suggestions and allocate tasks to execute the best ideas. Next establish recurring tasks to review and modify processes.

Value Stream Mapping

A tool called value stream mapping helps you visualize and understand the information and material flow that occurs as a product moves through the value stream. Make a process map of your existing workflow, mark each phase, and then eliminate or streamline the stages that do not add value.

Use SweetProcess to create a flowchart that shows every stage of your product’s development. Using the task management feature, identify steps that don’t provide value and make plans to eliminate them.

The 5S System

The 5S system is a set of procedures for setting up and managing workspaces: sort, set in order, shine, standardize, and sustain. The first steps in implementing 5S are clearing unnecessary items, organizing tools, tidying the workspace, and maintaining these practices over time. Sort necessary items and schedule routine cleaning and standardization tasks using SweetProcess checklists.

Process Analysis

Process analysis involves examining your current procedures to identify areas for improvement. You dissect each process into its parts, evaluate each one’s efficacy and efficiency, and then modify the procedure to reduce waste and boost output. Use SweetProcess’s tracking tools to identify inefficiencies in each phase of your process, then adjust your standard operating procedures (SOPs) to reflect the more effective methods.

Root Cause Analysis

Root cause analysis is used to determine the fundamental causes of problems or events. Instead of treating only the symptoms of a problem, employ techniques like the five whys or the fishbone diagram to get to the root of the problem. As problems develop, note them down, analyze them with a root cause analysis template and utilize SweetProcess’s collaborative tools to discuss and identify the underlying causes. Then, assign corrective tasks to address the issues.

Voice of the Customer

Gathering customer feedback is referred to as the voice of the customer (VOC). Before successfully implementing VOC, engage with your customers through surveys, interviews, and feedback forms to understand their needs and expectations. Then, use this knowledge to inform improvements. Create surveys and questionnaires using SweetProcess to get feedback from customers.

The Five Phases of Lean Six Sigma

Lean Six Sigma is based on the problem-solving approach known as DMAIC. It is a five-step process that is explained below.

Define Phase

This phase is the foundation of your lean Six Sigma project. Identify the problem, use the voice of the customer (VOC) data to understand what customers want, and establish quantifiable, unambiguous objectives. This phase ensures everyone is aligned with the project’s goals and scope.

Measure Phase

This stage involves collecting data to gain insight into the process’s current status. Compile baseline data, establish a thorough process map, and validate your measurement system. Before making any adjustments, this stage aids in precisely assessing the process’s performance.

Analyze Phase

Part of the analysis process involves digging deeper into the data to identify the root causes of errors or inefficiencies. Tools like fishbone diagrams and Pareto charts help find problems and analyze trends.

Improve Phase

You create and put into practice solutions for addressing the core problems identified in the analysis phase during the improvement phase. Come up with a list of possible solutions, test them on a small scale, and implement process improvements that work. The goal of this stage is to make long-lasting and efficient improvements.

Control Phase

The control phase supports the long-term maintenance of the improvements made. Monitor process performance with control charts, update SOPs to reflect new practices, and conduct regular audits. This phase helps in maintaining progress and prevents redundancy.

Examples of Implementing Lean Six Sigma

Let’s see how Lean Six Sigma can be applied to real-world problems.

Reducing IT Downtime

Imagine a data-driven approach to IT downtime. Lean Six Sigma allows you to pinpoint the root cause: Is it peak usage times or specific software crashes? By analyzing data and implementing targeted solutions like optimizing server capacity or preventative maintenance, you can significantly reduce downtime and get everyone back online faster.

Minimizing Manufacturing Defects

Lean Six Sigma can be a game changer for manufacturing quality. By collecting data on defect rates and analyzing the root cause, be it equipment malfunctions or a need for training, you can implement corrective actions. This might involve recalibrating machinery, developing targeted training modules, or implementing stricter quality control procedures.

Optimizing Environmental Impact

Lean Six Sigma can be a champion for the environment. Imagine analyzing your waste stream to identify areas for improvement, such as excessive material usage or energy consumption. You can then implement solutions like exploring recycled materials, optimizing production runs to minimize waste, or finding ways to reuse packaging materials. These changes, combined with data analysis, can lead to significant environmental benefits.

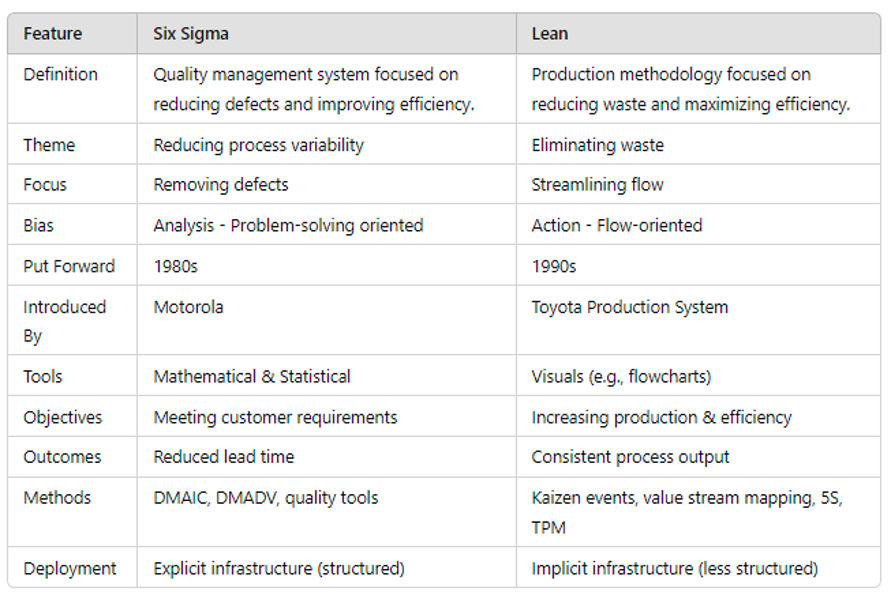

Six Sigma vs. Lean Six Sigma: Differences and Similarities

Lean and Six Sigma are both process improvement methodologies. Each methodology has its goals and objectives and can be used separately or in conjunction.

The thin line between lean and Six Sigma has continued to be blurred. Both focus on improving business processes to enhance efficiency, quality, and productivity. They prioritize meeting customer needs through data-driven decision-making and emphasize continuous improvement.

Both methodologies aim to reduce waste, involve employees at all levels, and standardize processes to ensure consistency. They utilize a variety of tools and techniques for process analysis and improvement. Additionally, Six Sigma and Lean encourage cross-functional collaboration and offer structured Lean Six Sigma training and certification programs.

Lean Six Sigma Belts and What They Mean for Your Business

Lean Six Sigma belts are a structured approach to learning about the lean Six Sigma technique. By implementing a belt system, organizations can create a tiered framework for ongoing process improvement.

White Belt

This is the first level of Lean Six Sigma certification, which will help you get a white belt and provide you with an overview of the methodology’s fundamental concepts and principles. White belts can identify areas for improvement and contribute to broader team efforts.

Yellow Belt

Yellow belts actively engage in improvement projects, building on the foundation of knowledge gained by white belts. They assist project leaders, gather information, and come up with creative ideas.

Green Belt

Gaining a green belt will expose you to Six Sigma methods for developing and improving products, services, and processes. Lean Six Sigma will be used, and process improvement initiatives will be managed by you. It gives you the capacity to oversee minor projects, carry out root cause analysis on data, and effect remedial measures.

Black Belt

Black belts are highly competent professionals who possess the know-how to oversee complex cross-departmental growth projects. They are knowledgeable in statistical analysis methods and Lean Six Sigma techniques. Black belts are in charge of identifying critical problems, leading interdisciplinary teams, and implementing impactful solutions.

Master Black Belt

Within the lean Six Sigma system, master black belts mentor and coach green and black belts. They ensure the methodology is applied consistently, offer strategic guidance for improvement projects, and support the overall achievement of the black belt training program.

Start Your Company’s Lean Six Sigma Journey With SweetProcess

Continuous improvement is no longer optional in today’s competitive business landscape—it is essential for your business’s survival. Lean Six Sigma provides a combination of techniques to optimize workflow, eliminate waste, and provide long-lasting benefits.

Leveraging SweetProcess will create a more efficient, customer-centric organization. Sign up for your free trial of SweetProcess today and take the first step toward achieving operational excellence within your organization.