Last Updated on May 6, 2025 by Owen McGab Enaohwo

Efficiency is key in any business. However, when you step into your office every morning, you’re immersed in routine activities: client meetings, email responses, product launches, and project updates.

Your team, a dedicated bunch of creatives and strategists, are stretched thin, juggling multiple tasks and deadlines. Despite their best efforts, projects seem to fall behind schedule, clients grow impatient, and opportunities slip through the cracks. As you scramble to salvage the situation, you can’t help but wonder: Is there a better way?

Business process improvement (BPI) offers a powerful approach to enhancing efficiency, reducing costs, and improving overall performance. But what exactly does it involve? This guide breaks it down, ensuring you can understand and apply these concepts to gain a competitive edge.

Table of Contents

What Is Business Process Improvement?

Why You Should Implement Business Process Improvement in Your Company

How to Improve a Business Process: A Step-by-Step Guide

How to Improve Your Business Process Using SweetProcess

11 Business Process Improvement Methodologies & Techniques

10 Real-Life Examples of Business Process Improvement From Which to Learn

Best Practices and Tips for Implementing Business Process Improvement in a Company

Challenges With Implementing Business Process Improvement in a Company

Frequently Asked Questions (FAQs) About Business Process Improvement

SweetProcess is your trusted partner in streamlining business operations and driving growth. Sign up now for a free trial and unlock the full potential of your organization.

What Is Business Process Improvement?

Business Process Improvement (BPI) is a strategic approach to enhancing efficiency, reducing costs, and boosting overall organizational performance. It involves analyzing existing processes, identifying areas for improvement, and implementing changes to streamline workflows and achieve better outcomes.

For instance, a retail store might streamline its checkout process to reduce wait time and improve customer satisfaction, similar to how a homeowner renovates their kitchen for a more streamlined cooking experience.

By implementing BPI initiatives, businesses can achieve tangible results, like increased productivity and cost savings, much like how a renovated house enhances comfort and functionality.

Why You Should Implement Business Process Improvement in Your Company

Staying competitive in today’s market requires more than maintaining the status quo. It necessitates a commitment to continuous improvement and innovation with business process improvement. Here is why:

Increase your team’s productivity and efficiency

Implementing BPI initiatives can enable your team to focus their time and energy on complex and strategic tasks by streamlining workflows, eliminating redundant tasks, and automating manual processes.

For example, a marketing team might use BPI to standardize its content creation process, which would result in faster turnaround times and improved resource allocation.

Improve product quality

BPI is not just about doing things faster; it’s also about doing them better. You can identify opportunities to improve product quality and consistency by analyzing and optimizing your business processes.

For instance, a manufacturing company may implement quality control measures at various stages of the production process to identify defects early on and ensure that only high-quality products reach the customer.

This enhances customer satisfaction and helps build a reputation for delivering superior products.

Enhance customer satisfaction and loyalty

It is no secret that customer satisfaction is non-negotiable. Implementing BPI initiatives focused on improving customer-facing processes, such as order fulfillment or customer support, can enhance the overall customer experience and foster loyalty. For instance, a restaurant implements BPI to streamline its reservation and seating processes, thereby reducing wait times and providing customers with a more pleasant dining experience, leading to repeat business.

Improve the morale of employees

Efficient and well-defined processes can positively impact employee morale and satisfaction. Employees who have clear guidelines and streamlined workflows feel more empowered and motivated to perform their tasks effectively. Additionally, involving employees in the BPI process by soliciting their feedback and suggestions for improvement can foster a sense of ownership and engagement.

Reduce cost of operations

One of the primary benefits of implementing BPI is its potential for cost savings. When you can identify and eliminate wasteful practices or inefficiencies in your processes, you can reduce operational costs and improve profitability. Think of a logistics company implementing BPI to optimize route planning and vehicle utilization. By doing this, they can reduce fuel costs and vehicle maintenance expenses, leading to significant cost savings over time.

Improve team communication and collaboration

Effective communication and collaboration are essential for the success of any organization. BPI can help break down silos and improve communication channels between different departments or teams within a company.

You can enhance transparency, accountability, and teamwork by standardizing processes and implementing tools or technologies like SweetProcess that facilitate collaboration. To take advantage of these benefits, consider signing up with SweetProcess today.

Streamline control and compliance

In regulated industries or environments where compliance is critical, BPI can help streamline control processes and ensure adherence to regulatory requirements. For example, a financial institution implementing BPI to automate its compliance monitoring processes can reduce the risk of errors or non-compliance and avoid costly fines or penalties.

While the desire to remain ahead of the competition is good, implementing business process improvement in your company offers far greater benefits than just staying ahead.

How to Improve a Business Process: A Step-by-Step Guide

Improving business processes is not a one-time task but an ongoing journey that should follow a structured approach.

Step 1: Understand Your Business Goals

The first step in improving a process is aligning it with your business goals. Take the time to clearly define your goals and how the process contributes to those goals.

Step 2: Collect Data From Relevant Stakeholders

Gather input and feedback from all relevant stakeholders involved in the process, including employees, managers, and customers. This data will provide valuable insights into the current state of the process, its pain points, and areas for improvement. It will also serve as the foundation for your process improvement effort and help you make informed decisions.

Step 3: Identify and Map Current Processes

Visualize the flow of work by mapping out the current state of the process from start to finish. Document each step involved, including inputs, outputs, decision points, and handoffs between individuals or departments. This process mapping exercise will help you identify inefficiencies and uncover opportunities for optimization.

Step 4: Analyze and Identify Areas for Improvement

After mapping out your current process, a Continuous Quality Improvement (CQI) approach ensures that inefficiencies are systematically addressed. Critically analyze the workflow to pinpoint bottlenecks, redundant steps, delays, and errors that hinder performance.

By leveraging CQI, you can prioritize areas for improvement based on their impact on business goals and the feasibility of change. This ongoing cycle of assessment and refinement fosters a culture where efficiency and effectiveness are continuously optimized.

Step 5: Quantify Benefits

Before implementing changes, quantify the potential benefits of process improvement. Estimate the expected cost savings, productivity gains, or other benefits resulting from optimizing the business process. Having clear metrics and goals will help you track progress and evaluate the success of your improvement efforts.

Step 6: Create an Improvement Plan

Based on your analysis, develop a comprehensive process improvement plan that outlines specific changes to be made, timelines for implementation, and responsibilities for each task. Ensure the plan is realistic, achievable, and aligned with your business goals. Communicate the strategy to all stakeholders involved to gain buy-in and support.

Step 7: Implement Changes

Execute the improvement plan according to the established timelines and milestones. Monitor progress closely and address any challenges or issues that arise along the way. Keep stakeholders informed and involved throughout the implementation process to maintain engagement and accountability.

Step 8: Monitor and Evaluate Results

Once the changes have been implemented, monitor the revised process’s performance closely. Track key metrics and indicators to assess whether the improvements have achieved the desired outcomes and identify areas that may require further refinement.

Step 9: Analyze the Performance of New Changes

Continuously analyze and evaluate the improved process’s performance over time. Get feedback from stakeholders and incorporate lessons learned into future improvement efforts.

These nine steps can systematically improve your business processes and drive tangible results for your organization.

For instance, a manufacturing company seeking to streamline its production process could follow these steps:

(a) Identify bottlenecks, such as repeated processes like email sending or scheduling, that hinder workflow efficiency.

(b) Optimize workflows by assigning tasks to each employee, ensuring clarity on responsibilities and oversight, thus enhancing coordination and employee productivity.

(c) Enhance overall efficiency by implementing business process automation tools to reduce manual tasks and improve resource allocation.

Read our article on business process methodologies to learn more about implementing these steps effectively.

How to Improve Your Business Process Using SweetProcess

At Belvidere Community School District, director of quality assurance Sarah Brenner faced the challenge of streamlining operations. The district’s procedures and documentation were scattered far and wide, stuck in individual employees’ Google Docs and Word files, some even handwritten. This lack of centralization made it nearly impossible for staff, parents, and other stakeholders to access critical information when needed.

Sarah knew they needed a better way to organize and share their operational knowledge. After extensively researching potential solutions, she discovered SweetProcess and knew she had found the answer. SweetProcess provided a centralized, easily searchable knowledge base to house all of the district’s procedures, policies, and best practices.

The impact was transformative. Parents could now quickly find details on everything from athletic policies to student handbooks with just a few clicks. Staff onboarding became a breeze as new hires could independently study processes instead of shadowing colleagues. What was once an opaque tangle of scattered information became an accessible, transparent system.

Sarah’s vision paid off. Streamlining their operations with SweetProcess instilled confidence across the Belvidere School District. If you, too, are ready to take your business process improvement to the next level, following in Sarah’s footsteps is a great start.

How to Create a Procedure Using SweetProcess

Gone are the days of cumbersome, outdated procedure manuals. With SweetProcess, creating procedures is as easy as 1-2-3.

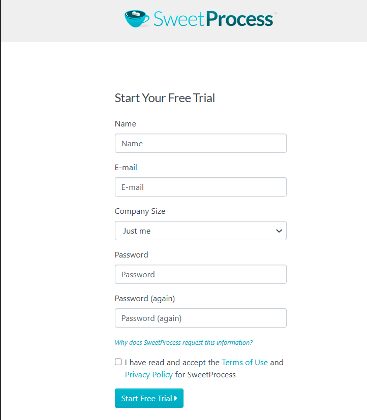

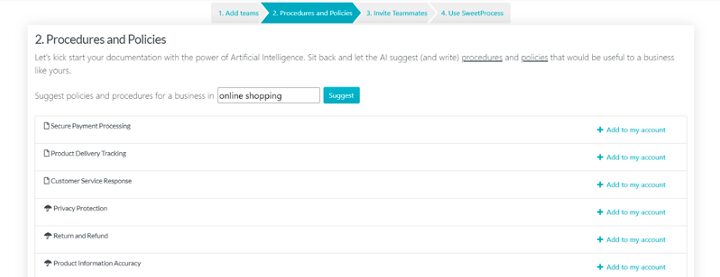

Step 1: Log in or sign up for a SweetProcess account.

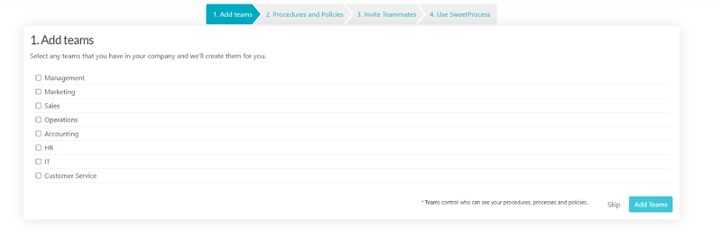

If you are just signing in, you will be required to complete some steps, such as adding your team.

- If you have a team, you can add them from the start.

- After adding your team, create your procedure, or skip this step until you are logged in.

- You also get to import your already documented process if you have one.

- For the last stage, you will be asked to invite your teammates.

You can always skip these steps and continue with them later.

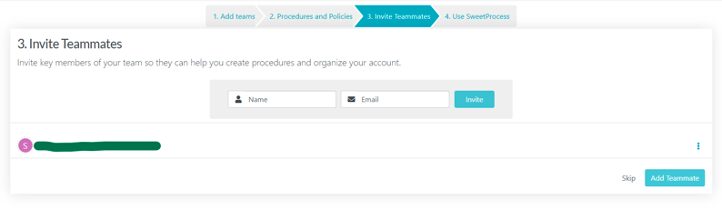

Once you have signed up or logged in, you can access the dashboard interface.

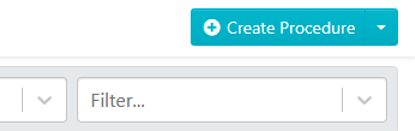

Step 2: Navigate to the “Procedure” section.

Step 3: Name the procedure, add the procedure to a team or multiple teams, and click “Continue.”

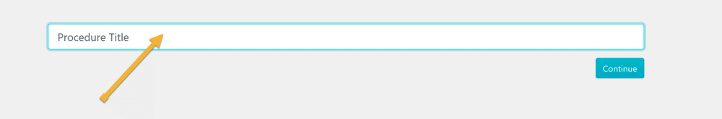

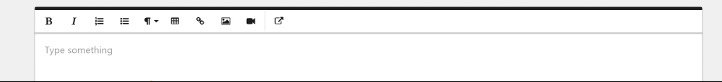

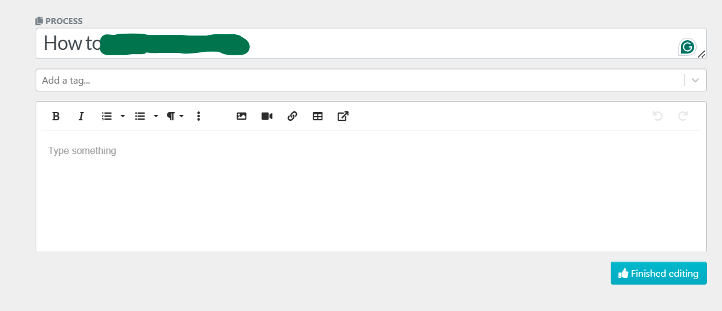

Step 4: Click on the title of the procedure to add a description.

Step 5: Enter tags.

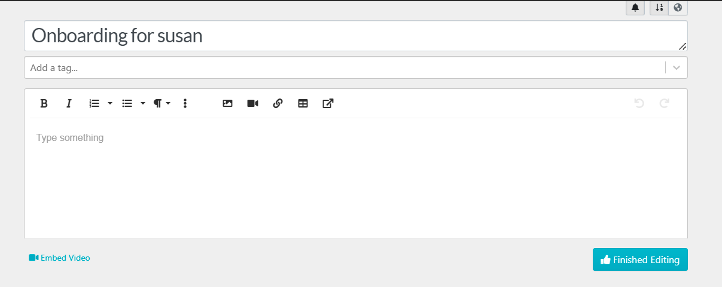

Step 6: Click on the “Add a Step” button.

Step 7: Give the step a title and description.

You can even add images, videos, and links to the steps.

Step 8: Click on “Finished Editing” to save.

To insert a new step, click the “Add a step” button. Follow the same process outlined in steps 6, 7, and 8 to input and save the details of the new step. Continue repeating this until you have included all the steps to document the procedure fully.

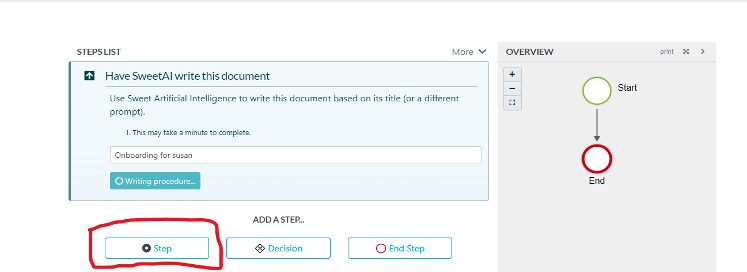

You can view the procedure as a flowchart, as seen below.

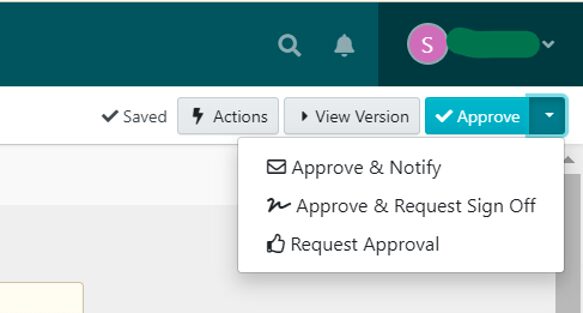

Step 9: After editing the procedure, select “Approve” to finalize it as the live version.

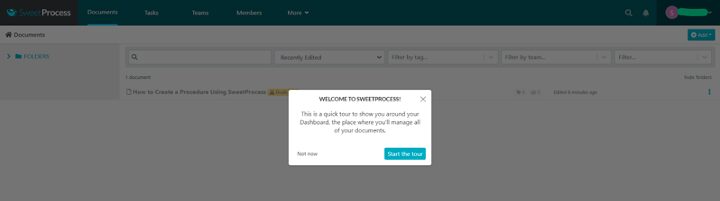

Step 10: All done? Click on “Procedures” to return to the dashboard, where you can view and manage all your procedures.

With SweetProcess, creating and updating procedures has never been easier. Sign up and start your free trial today (no credit card required).

How to Create a Process on SweetProcess

Whether you’re streamlining workflows, automating repetitive tasks, or optimizing resource allocation, here’s how you can do it easily with SweetProcess.

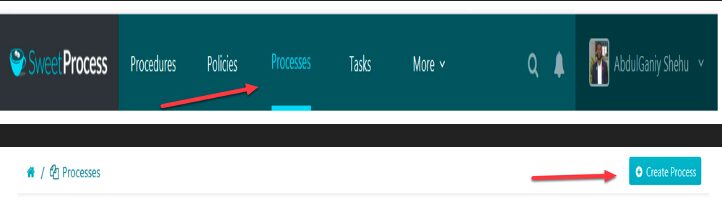

Step 1: Once you log in or sign up for a SweetProcess account, navigate to the “Process” section.

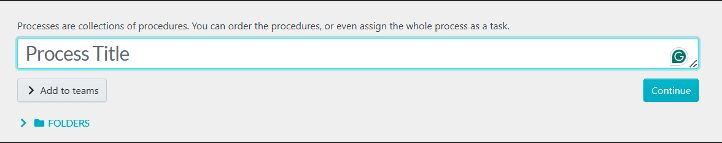

Step 2: Enter the desired process name.

Indicate the team or teams responsible for the process and click on the “Continue” button to proceed.

Step 3: For additional details, click on the process title and provide a comprehensive description.

How to Manage Your Procedures and Processes in SweetProcess

Effectively managing your business processes involves more than documenting them; it involves execution, monitoring, and continuous improvement.

SweetProcess excels at transforming how you handle these elements by offering a comprehensive, user-friendly platform. But we wouldn’t want you to just take our word for it.

The experience of All Residential Real Estate with SweetProcess underscores the significant efficiencies and enhancements that can be achieved.

Perry Beebe, the managing director at All Residential Real Estate, found his company grappling with the limitations of a paper-based system. This system made it difficult to keep processes up-to-date and accessible. The inefficiencies caused by outdated documentation were clear obstacles to productivity and operational consistency.

Perry found SweetProcess to be a solution for managing the company’s procedures. With its digital procedures and media capabilities, SweetProcess helped streamline processes and improve comprehension and execution. Employees could also access standardized procedures easily, ensuring tasks were performed consistently and correctly across the board.

One of the standout benefits that SweetProcess brought to All Residential Real Estate was the effective onboarding process for new hires. This process drastically reduced the learning curve by providing them with all the necessary tools and information through the platform, significantly cutting down on the time and resources spent on training.

Perry’s experience highlights the importance of moving away from outdated methods and embracing technology to improve efficiency. His advice to other business leaders is clear:assess your current procedures and consider how a tool like SweetProcess can make them more efficient, reliable, and scalable.

If your business is facing similar challenges, it’s time to consider SweetProcess. Sign up for a 14-day free trial to see how SweetProcess can revolutionize your operations—no credit card is required.

With its robust features designed to manage, track, and improve business processes, SweetProcess is more than just a tool; it’s a transformational platform. Hence, once your procedures and processes are documented, it’s time to implement them. Below is how you can achieve that.

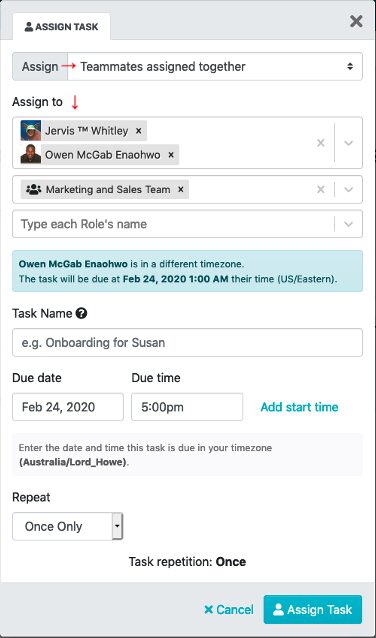

How to Assign and Track Tasks on SweetProcess

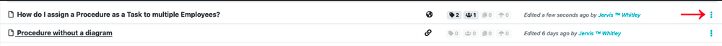

Step 1: Navigate to the task you want to assign under either “Procedures” or “Process” on your SweetProcess dashboard.

Step 2: Click on the three-dot menu next to your chosen item.

Step 3: Click on “Assign as Task” from the dropdown menu.

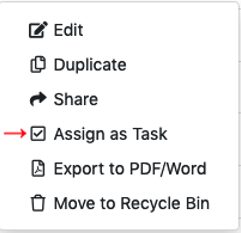

Another way is to do this from the “Actions” menu when viewing the procedure or process in detail.

Step 4: Decide if you’re assigning a single task to one team or multiple tasks to several team members.

Step 5: Choose teammates you want tasks assigned.

Step 6: Detail the task. Specify the task’s starting time and deadline. You can also decide if you want teammates to start the task early.

By default, tasks are one-time, but you can set them to repeat (e.g., every third Friday of the month, weekly, etc.) based on requirements.

Step 7: After entering all the details, assign the task.

Both you and your team members will receive notifications regarding the status of tasks, such as alerts for overdue tasks, notifications upon completion, or reminders for upcoming tasks.

11 Business Process Improvement Methodologies & Techniques

Business process improvement encompasses a broad spectrum of activities aimed to drive efficiency and streamline operations. These methodologies and techniques provide a structured framework for effective implementation. Below are 11 essential business process improvements and methodologies you should know about.

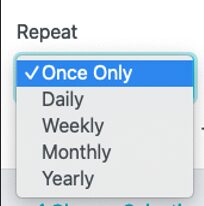

Kanban

Kanban is a streamlined approach to project management, drawing principles from agile methodologies and just-in-time (JIT) manufacturing. It uses visual signals—often in the form of cards—to manage work processes and promote continuous improvement. This methodology’s core lies in its Kanban boards, visual tools that map out the workflow of a project from start to finish.

A basic kanban board features columns such as To Do, In Progress, and Complete, but can be customized to fit various project needs. Each task, represented by a card, moves through these columns, detailing the process stage, responsible personnel, time estimates, and specific requirements needed for progression.

Source: Officetimeline

Key benefits of implementing kanban include:

- Enhanced Efficiency and Productivity: Kanban reduces waste and maximizes efficiency by limiting the amount of work in progress.

- Workflow Management: Kanban boards provide a clear overview of workflows, making it easier to manage and adjust them as needed.

- Flexibility: Changes in the workflow or task priorities can be made easily and with minimal disruption.

- Risk Management: Problems and risks are identified quickly, allowing immediate action to mitigate issues.

Kanban is particularly beneficial in environments where tasks vary in priority and complexity. It is a popular choice for software development teams, manufacturing plants, and service-based businesses aiming to maintain a continuous flow of work and deliver high-quality outcomes.

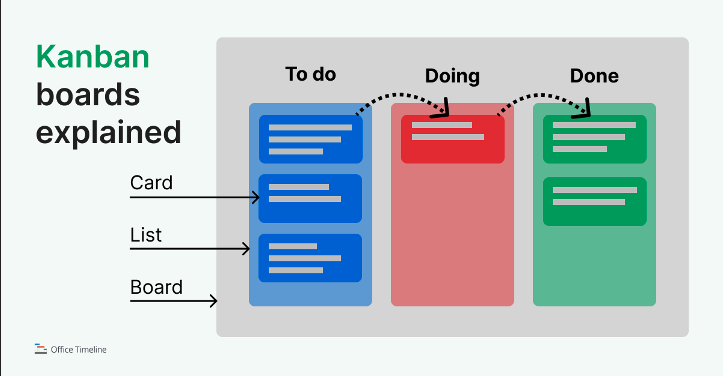

Kaizen

Kaizen, a Japanese term that means “change for the better,” is a business philosophy focused on gradually enhancing operations through small, incremental changes involving all employees. This philosophy operates on the principle that small, ongoing, positive changes can reap significant improvements.

The 5S system is a key aspect of Kaizen, emphasizing organization and efficiency:

- Seiri (Sorting): Eliminate unnecessary items or inefficient processes to streamline the workspace.

- Seiton (Orderliness): Arrange tools and materials for easy access and use.

- Seiso (Clean): Maintain cleanliness to prevent malfunctions and improve safety.

- Seiketsu (Standardizing): Establish procedures to sustain the first three S’s.

- Shitsuke (Sustaining): Implement routines to ensure continuous adherence to the 5S approach.

Source: gkdaring

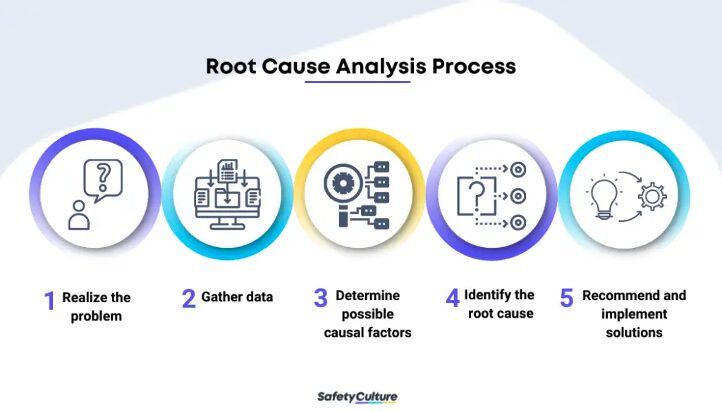

Root Cause Analysis

Root Cause Analysis (RCA) is a structured method for understanding the fundamental reasons behind incidents or problems. It focuses on uncovering the underlying causes rather than just addressing the symptoms.

Key steps in root cause analysis include:

- Define the problem: Clearly articulate the issue or incident that requires analysis.

- Collect data: Gather relevant information and evidence related to the issue.

- Identify causal factors: Determine the factors contributing to the difficulty, considering both immediate and underlying causes.

- Identify the root cause(s): Dig deeper to uncover the primary factors that led to the incident.

- Implement solutions: Develop and implement corrective actions to address the root cause(s).

You can also use any of these root cause analysis templates if you don’t want to start from scratch.

Source: SafetyCulture

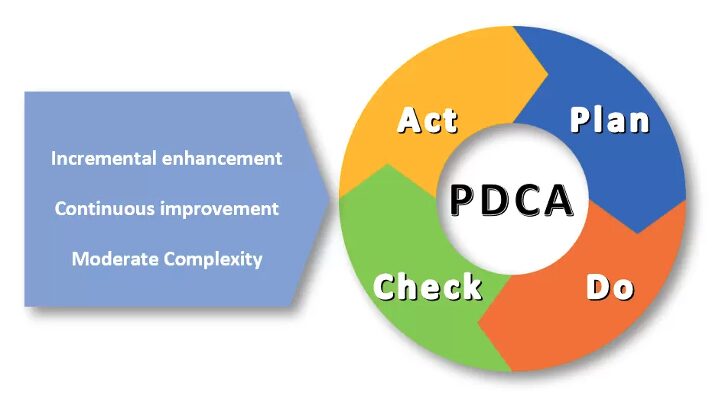

Plan Do Check Act (PDCA)

The plan-do-check-act (PDCA) cycle, also known as the Deming Wheel or Shewhart cycle, is a systematic method for business process management focused on continuous improvement. It guides teams through four iterative steps: plan, do, check, and act.

- Plan: Identify project objectives, stakeholders, timeline, and risks.

- Do: Implement the project plan on a small scale.

- Check: Review the test to ensure alignment with the plan.

- Act: Roll out the full project or process improvement based on the results.

Source: Wevalgo

The PDCA cycle is a versatile tool applicable in various scenarios, such as starting new improvement projects, developing or refining processes, products, or services, and optimizing repetitive work processes. It fosters constant improvement and growth within organizations and is integral to lean management practices.

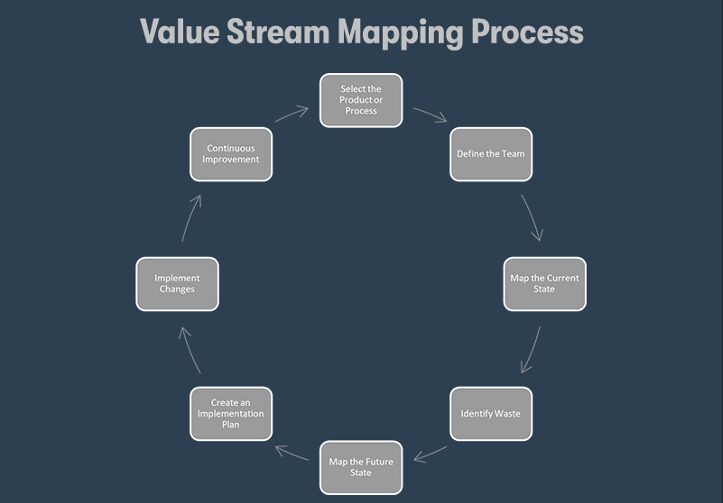

Value Stream Mapping

Value Stream Mapping (VSM) is a lean manufacturing technique that enables organizations to visualize and optimize their product or service delivery processes. The key features and benefits of value stream mapping include:

- Identifying waste: This includes waiting times, overproduction, and unnecessary processing.

- Visualizing workflow: To provide a clear understanding of value-adding and non-value-adding activities.

- Enabling continuous improvement: To allow organizations to focus on future improvements and optimize workflow efficiency.

Source: PurpleGriffon

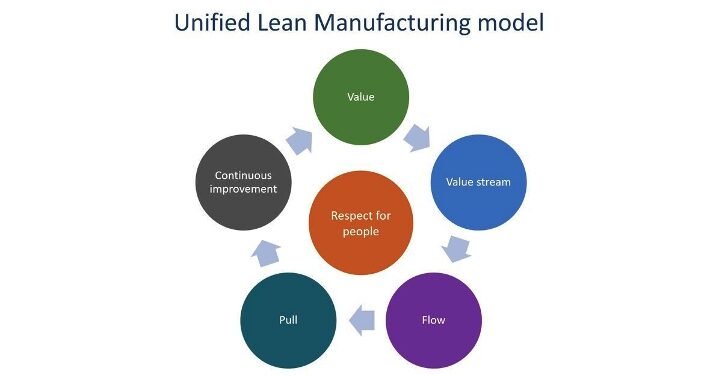

Lean Manufacturing

Lean manufacturing is a production methodology aimed at reducing waste, improving efficiency, and cutting costs to enhance productivity and customer value. It emphasizes continuous improvement and prioritizes processes that add value from the customer’s perspective.

Lean manufacturing focuses on the following key principles:

- Value: Focus on delivering what customers are willing to pay for and eliminate anything that doesn’t contribute to value creation.

- Value stream mapping: Analyze the entire production process to identify and eliminate waste, ensuring smooth workflows.

- Flow: Establish seamless production processes to minimize delays and interruptions, maximizing efficiency.

- Pull system: Align production with customer demand to avoid overproduction and unnecessary inventory, reducing costs and improving responsiveness.

- Perfection: Pursue ongoing improvement in all aspects of operations to achieve the most efficient and effective processes.

Source: We Valgo

Click here to read our article to learn more about lean process improvement.

Six Sigma

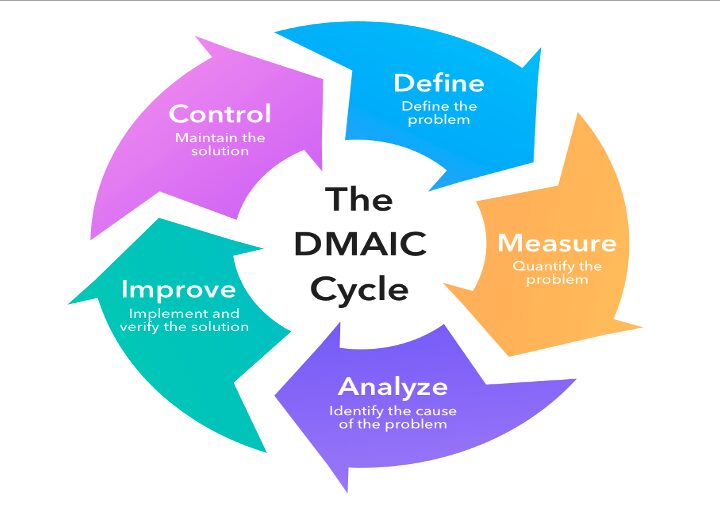

Six Sigma is a process improvement methodology that aims to improve business processes by reducing defects, minimizing variation, and enhancing quality and efficiency. It employs a structured approach called DMAIC (define, measure, analyze, improve, and control).

- Define: Identify the problem, set goals, and outline the project scope.

- Measure: Collect data to understand the current state of the process.

- Analyze: Identify root causes using data analysis and tools.

- Improve: Implement solutions to address root causes.

- Control: Maintain improvements and ensure consistent performance.

The DMAIC approach not only enhances product quality but also improves customer satisfaction, decreases costs, and boosts profitability across various industries, including healthcare, finance, and manufacturing.

Source: La Plage Academy

Expanding on Six Sigma, Lean Six Sigma integrates lean manufacturing principles and Six Sigma principles. This combination leverages the strengths of both methodologies to streamline operations, enhance efficiency, and deliver exceptional value to customers.

Total Quality Management (TQM)

Total Quality Management (TQM) is a comprehensive approach to long-term success through customer satisfaction, focusing on continuous improvement in all aspects of an organization.

Key principles of TQM include:

- Customer focus: Aims to surpass customer expectations to enhance customer loyalty and expand the base.

- Employee involvement: Engages all levels of staff (from top management to floor staff) in quality improvement, promoting accountability and ownership.

- Process-centric approach: Concentrates on understanding and refining each step of a process to minimize waste and errors.

- System integration: Treats the organization as a network of interconnected processes, enhancing overall performance.

- Continuous improvement: Constantly seeks enhancements, utilizing strategies like PDCA (plan-do-check-act) to drive innovation.

- Fact-based decision making: Employs data analysis to ensure decisions are objective and strategic.

- Effective communication: Maintains open, transparent channels for ongoing feedback and discussion of progress.

Source: Corporate Finance Institue

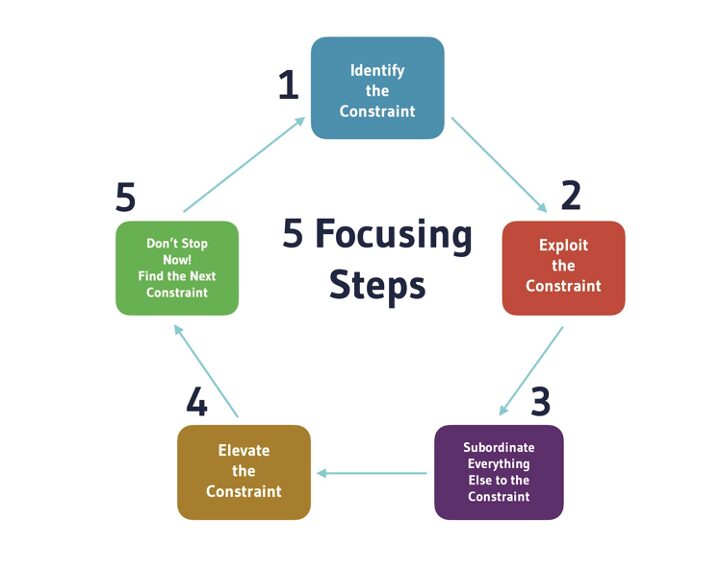

Theory of Constraints (TOC)

The theory of constraints (TOC) is a process management philosophy designed to help organizations achieve their goals by identifying and addressing the most significant constraints that hinder process performance. It revolves around a process known as the five focusing steps, listed below:

Step 1: Identify the constraint.

Step 2: Exploit the constraint.

Step 3: Subordinate everything else to the constraint.

Step 4: Elevate the constraint.

Step 5: Repeat the process.

Source: TXM Lean Solutions

TOC utilizes throughput accounting, which evaluates decisions based on their impact on operating expenses and inventory, aligning financial analysis with the goal of continuous process improvement. The thinking processes, another toolset within TOC, help systematically analyze and solve underlying problems. Implementing TOC has several benefits, including increased profitability, faster improvements by focusing on the most critical areas, better capacity and quality, and reduced lead times and inventory levels.

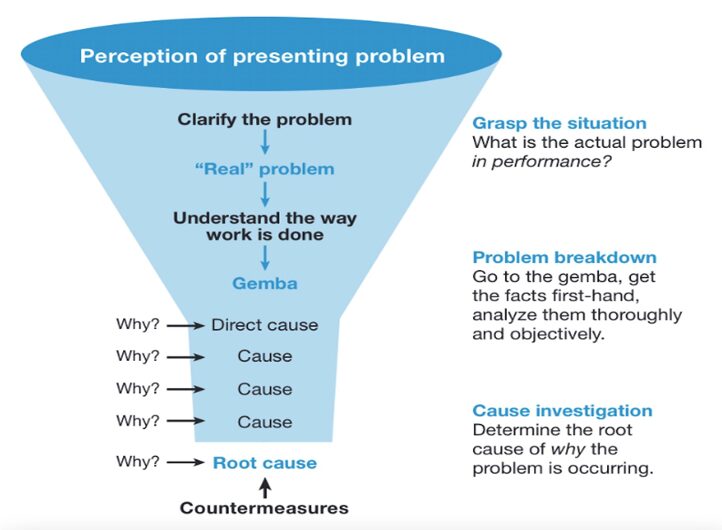

Five Whys Analysis

The five whys analysis is a simple but powerful technique for identifying the root cause of a problem by asking “why” five times. It helps uncover deeper insights into the underlying issues and enables organizations to address the root cause rather than just the symptoms.

The steps are straightforward. Consider a manufacturing company experiencing a high rate of product defects. You have defined the problem as “product defects are occurring at an alarming rate.” Then, applying the five whys analysis, you ask:

- Why are there defects? Because the products are not meeting quality standards.

- Why are they not meeting quality standards? Due to incorrect assembly procedures.

- Why are the assembly procedures incorrect? Because workers are not adequately trained.

- Why are workers not adequately trained? There is a lack of comprehensive training programs.

- Why is there a lack of comprehensive training programs? Due to budget constraints and management oversight.

Source: Lean Enterprise Institute

The five whys analysis is applicable across various industries and can be used to solve a wide range of problems, from manufacturing defects to customer service issues. Its systematic approach empowers organizations to make informed decisions and drive continuous improvement.

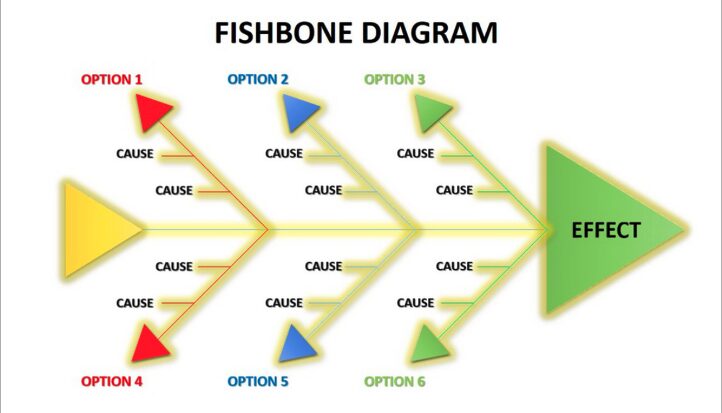

Fishbone Diagram

A fishbone diagram, also known as an Ishikawa diagram, is a visual tool for identifying the potential causes of a specific event or problem. It provides a structured approach to brainstorming causes and offers a systematic framework for root cause analysis (RCA) and problem-solving.

Source: Unichrone

Using a fishbone diagram involves several steps:

- Identify the problem and place it at the head of the diagram.

- Brainstorm all possible causes and categorize them accordingly.

- Visualize relationships between causes and the main problem.

- Analyze causes and prioritize action based on their impact.

- Develop and implement solutions based on identified causes.

By visually mapping out these causes, organizations can effectively address root issues and improve processes or outcomes.

10 Real-Life Examples of Business Process Improvement From Which to Learn

Business process improvement is not just a theoretical concept; it has tangible benefits when applied in real-life scenarios. Here are ten business process improvement examples you can implement to enhance your business operations.

Streamlining Inventory Management

Company: A retail chain

Problem: The retail chain struggled with overstocked items in some stores and frequent stockouts in others. This led to inefficient use of warehouse space, increased carrying costs, and lost sales opportunities due to inventory shortages.

Business process improvement strategy: Implement a centralized inventory management system to track stock levels across all stores in real time. Utilize data analytics to forecast demand and optimize inventory levels. Introduce automated reorder points to replenish stock automatically when levels drop below a certain threshold.

Preventing Shipping Errors

Company: A pharmaceutical distributor

Problem: A pharmaceutical distributor delivers medications to various healthcare facilities. In one instance, a delivery driver mistakenly left a shipment of temperature-sensitive vaccines in an unrefrigerated area, compromising their efficacy and causing a significant financial loss.

Business process improvement strategy: Update operating procedures to include mandatory temperature checks and monitoring during transport. Implement training programs for delivery staff to ensure compliance with handling protocols for sensitive medical supplies. Utilize technology such as temperature-tracking devices and GPS to monitor shipments in real time and prevent errors.

SweetProcess offers a platform for documenting and training staff on updated procedures, ensuring strict adherence to protocols and minimizing the risk of errors. Sign up for your free trial today.

Automating Invoice Processing

Company: An accounting firm

Problem: The accounting firm was overwhelmed with manual invoice processing, which led to payment delays, missed deadlines, and errors in financial reporting.

Business process improvement strategy: Implement an automated invoice processing system to streamline the receipt, approval, and payment of invoices. Utilize optical character recognition (OCR) technology (available with SweetProcess) to extract data from invoices and integrate with accounting software for seamless processing. Train staff on the new system and monitor its effectiveness for continuous improvement.

Enhancing Safety Protocols

Company: A manufacturing plant

Problem: The manufacturing plant experienced frequent workplace accidents and safety incidents, resulting in injuries, downtime, and regulatory fines.

Business process improvement strategy: Review and update safety protocols and procedures to ensure compliance with industry standards and regulations. Provide comprehensive safety equipment like PPE (personal protective equipment), onboarding training for all employees, and implement regular safety audits and inspections. Encourage a culture of safety awareness and empower employees to report hazards and suggest improvements.

Implementing Remote Work Policies

Company: An IT services company

Problem: The IT services company faced challenges in attracting and retaining talent due to a lack of flexibility in work arrangements.

Business process improvement strategy: Develop and implement remote work policies and procedures to allow employees to work from home or remotely. Provide necessary technology and tools to support remote work, such as virtual private networks (VPNs) and collaboration software. Establish clear communication channels and performance metrics to ensure accountability and productivity.

SweetProcess integrates with more than 1,000 apps, including Slack, Gmail, Evernote, and Mailchimp. Start here.

Enhancing Data Security

Company: A financial institution

Problem: The financial institution experienced data breaches and cybersecurity threats that compromised sensitive customer information and eroded trust.

Business process improvement strategy: Strengthen data security measures by implementing encryption protocols, access controls, and multi-factor authentication. Conduct regular cybersecurity training for employees to raise awareness of potential threats and best practices for data protection. Perform regular security audits and vulnerability assessments to identify and address potential weaknesses in systems and processes.

With SweetProcess, you can streamline security measures, disseminate training materials efficiently, and integrate them into security audits for continuous improvement.

Reducing Production Waste

Company: A manufacturing company

Problem: The manufacturing company faced high levels of waste in production processes, including material waste, rework, and scrap.

Business process improvement strategy: Implement lean manufacturing principles to identify and eliminate waste throughout the production process. Streamline workflows, optimize equipment usage, and standardize procedures to improve efficiency. Utilize data analytics to monitor production metrics and identify areas for further improvement.

Streamlining Confusing Workflows

Company: A marketing agency

Problem: The marketing agency struggled with complex and convoluted workflows, leading to delays, miscommunication, and decreased productivity.

Business process improvement strategy: Simplify and streamline workflows by mapping out existing processes, identifying bottlenecks and inefficiencies. Implement workflow automation tools and project management software like SweetProcess to standardize processes, improve collaboration, and track progress more effectively. Provide training and support to ensure employees understand and adhere to the new workflows.

Improving the SLA

Company: A customer support center

Problem: The customer support center faced challenges in meeting service level agreements (SLAs) and responding to customer inquiries in a timely manner.

Business process improvement strategy: Review and revise SLAs to ensure they are realistic, achievable, and aligned with customer expectations. Implement performance monitoring and reporting systems to track key metrics and identify areas for improvement. Provide ongoing training and development opportunities for customer support staff to enhance their skills and efficiency.

Planning for Process Failures

Company: An IT infrastructure provider

Problem: The IT infrastructure provider experienced frequent system outages and failures, resulting in downtime and service disruptions for clients.

Business process improvement strategy: Develop and implement contingency plans and disaster recovery procedures to mitigate the impact of system failures. Conduct regular risk assessments to identify potential vulnerabilities and weaknesses in infrastructure and systems. Establish clear protocols for responding to emergencies and communicating with clients during downtime events.

Don’t miss out on the opportunity to take your business to the next level. Sign up for your free trial of SweetProcess now and experience the difference for yourself.

Best Practices and Tips for Implementing Business Process Improvement in a Company

To effectively implement business process improvement (BPI) in your company, consider the following best practices and tips:

Foster a Culture of Continuous Improvement

Imagine a workplace where every member of your team feels not just encouraged but empowered to contribute ideas to make things better. You’re not just encouraging innovation; you’re cultivating a mindset where every improvement, no matter how small, is celebrated as a step forward. Encourage your team to share their insights, ideas, and suggestions for improvement, and watch as innovation flourishes.

Celebrate Achievements and Learn From Setbacks

Celebrate the successes—big and small—that come from your business process improvement efforts. Acknowledge the hard work, dedication, and ingenuity of your team members, and let them know that their contributions are valued and appreciated. And when setbacks occur, as they inevitably will, view them not as failures but as opportunities for growth and learning.

Establish Clear Goals and Metrics

Clearly define the objectives of your BPI initiatives and establish measurable metrics to track progress. When everyone understands the desired outcomes and knows how success will be measured, they can align their efforts accordingly.

Establish Standards and Procedures

Consistency is key to efficiency. Establishing standardized procedures ensures that everyone is working from the same playbook, reducing errors and streamlining business operations. Clear standards facilitate smoother operations and make it easier to identify areas for improvement.

Create a Detailed Improvement Plan

Success rarely happens by chance; it’s the result of careful planning and execution. Develop a detailed improvement plan that outlines the steps, timelines, and responsibilities for implementing your BPI initiatives. Break down your goals into manageable tasks, assign responsibilities, and set deadlines to keep everyone on track and accountable.

Use the Right Technology

Invest in process improvement tools that support your BPI efforts. Whether it’s process mapping software, workflow automation solutions, or data analytics platforms, leveraging the right technology can significantly enhance efficiency and effectiveness. Choose tools that align with your organization’s needs and facilitate collaboration and communication among team members.

Measure and Track Progress

Data is the lifeblood of continuous improvement. Regularly monitor and measure the effectiveness of your BPI initiatives using key performance indicators (KPIs) and metrics. Analyze the data to identify trends, patterns, and areas for improvement, and use these insights to inform your decisions and strategies.

Involve and Seek Feedback From Employees

When employees feel valued and engaged, they become invested in the success of your BPI initiatives. Involve employees at all levels in the BPI process, encourage their participation, and solicit their feedback. Empower them to take ownership of their work and contribute ideas for improvement.

Use Data-Driven Decision Making

Base process improvement decisions on data and evidence rather than assumptions or intuition and leverage analytics to identify trends, patterns, and opportunities for optimization.

Challenges With Implementing Business Process Improvement in a Company

Implementing Business Process Improvement (BPI) initiatives can be rewarding, but it’s not without its challenges. Understanding these challenges and how to overcome them is essential in ensuring the success of your BPI initiatives. Here are some common challenges you may encounter:

Integration and Alignment Issues

One of the primary challenges with implementing BPI is ensuring that new processes are integrated seamlessly into existing workflows and aligned with the organization’s overall goals and objectives. Lack of alignment can lead to confusion, resistance, and inefficiency, hindering the effectiveness of BPI efforts.

Lack of Employee Engagement

Engaging employees in the BPI process is critical to its success. However, many organizations struggle to foster a culture of engagement and involvement among their workforce. Without active participation from employees at all levels, BPI initiatives are likely to falter and fail to deliver the desired results.

Insufficient Training

Proper training is essential for employees to understand new processes, tools, and technologies introduced as part of BPI initiatives. However, many organizations overlook the importance of training, leaving employees ill-equipped to adapt to change effectively.

Resistance to Change

Change is never easy, and resistance to change is a common challenge faced by organizations implementing BPI. Employees may feel threatened by the prospect of change, fearing job insecurity or disruption to their routines. Thus, overcoming resistance to change requires effective communication, leadership, and a supportive organizational culture that values innovation and continuous improvement.

Difficulty in Measuring Results

Measuring the success of BPI initiatives can be challenging, particularly when it comes to quantifying the impact on key performance metrics and outcomes. Without clear metrics and measurement systems in place, it’s difficult to assess the effectiveness of BPI efforts accurately.

Communication Gap

Effective communication is essential for ensuring that BPI initiatives are understood, embraced, and implemented successfully across the organization. However, many organizations struggle with communication gaps, leading to misunderstandings, confusion, and resistance. Bridging the communication gap requires proactive, transparent communication channels that keep employees informed and engaged throughout the BPI process.

Improve Your Business Process Seamlessly Using SweetProcess

Now that you understand the importance of optimizing your workflows and processes, it’s time to take action. And with SweetProcess, improving processes has never been easier.

SweetProcess offers a seamless solution for streamlining operations, enhancing efficiency, and driving growth. With intuitive features like procedure creation, process mapping, and task management, SweetProcess empowers you to optimize your business processes with ease. Whether you’re a small startup or a multinational corporation, SweetProcess has the tools you need to succeed.

So why wait? Sign up for a free trial of SweetProcess today and start improving your business processes seamlessly. With SweetProcess, you can unlock new levels of efficiency, productivity, and success for your organization. Don’t let inefficiency hold your company back—unleash your organization’s full potential with SweetProcess.

Ready to take the next step toward your business process excellence? Start here.

Frequently Asked Questions (FAQs) About Business Process Improvement

Is process improvement a one-time effort or an ongoing process?

Process improvement is an ongoing journey, not a one-time event. While you may start with a specific BPI initiative to enhance efficiency and productivity, true success comes from continually reassessing and refining your processes over time.

How do you get started with process improvement?

Start by identifying areas of your business that could benefit from improvement, whether it’s streamlining workflows, reducing costs, or enhancing customer satisfaction. Then, gather input from key stakeholders, analyze current processes, and develop a plan for implementation.

How do you identify process improvement opportunities?

Start by mapping out your existing processes and identifying bottlenecks, inefficiencies, or pain points. Then consider factors such as customer feedback, employee input, industry best practices, and technological advancements to uncover opportunities for improvement.

How does business process improvement affect employee engagement?

Involving employees in the improvement process makes them feel valued, empowers them, reduces frustration, and improves job satisfaction, leading to higher engagement levels.