Last Updated on February 25, 2025 by Owen McGab Enaohwo

![What Is Continuous Quality Improvement? [+Steps & Tools]](https://www.sweetprocess.com/wp-content/uploads/2025/02/continuous-quality-improvement.jpg)

If you’re here because your business feels about as organized as a toddler’s toy box after Christmas morning, you’re going to love continuous quality improvement (CQI). It’s not just another buzzword that consultants throw around to justify their expensive lunch tabs.

Imagine your business is like a car engine. Sure, it might make some weird noises or burn more fuel than it should, but it gets you where you need to go, right? That’s where most businesses stop. They’re content with “good enough.” But you’re not here for “good enough,” are you? You’re here because you want your business purring like a finely tuned Ferrari.

That’s exactly what continuous quality improvement is about. It’s the difference between playing whack-a-mole with problems and building a system that gets better every single day.

Ready to streamline your processes in less than 30 days? Start a free trial of SweetProcess and experience organized workflows without the chaos. Your future self will thank you for not being another “we’ll fix it later” procrastinator.

Table of Contents

What Is Continuous Quality Improvement?

Five Features of Continuous Quality Improvement

Why Is Continuous Quality Improvement Important for a Business?

How to Streamline Your Company’s CQI Process Using SweetProcess

6 Steps in Continuous Quality Improvement (CQI)

Tools to Perform Continuous Quality Improvement (CQI)

Continuous Quality Improvement in Healthcare: How to Implement It

Continuous Quality Improvement vs. Lean Process Improvement

Enhance Your Company’s CQI Process With SweetProcess

What Is Continuous Quality Improvement?

Continuous quality improvement (CQI) is a structured, ongoing approach to refining business processes. As consistent training yields better fitness results, regular assessments and adjustments lead to operational excellence. CQI ensures your workflows evolve consistently, helping avoid stagnation and improving efficiency over time. Just like you can’t get ripped by working out once and calling it a day, you can’t improve your business by fixing things once and walking away like you’ve solved world hunger.

CQI is a systematic, never-ending approach to improving your business processes. It’s about:

- Constantly Looking for Problems: You know that friend who always points out what’s wrong with everything? That’s you now but in a productive way. You’re actively hunting down inefficiencies like they owe you money.

- Making Small, Consistent Changes: Forget those massive overhauls that give everyone anxiety attacks. We’re talking about steady, incremental improvements that add up faster than your coffee budget.

- Getting Everyone Involved: From Janet in accounting to Bob in maintenance, everyone’s got a say. It’s like a democracy, but to make things suck less.

It’s not about being perfect (spoiler alert: perfection is about as real as your cousin’s “candid” social media posts). It’s about being better today than yesterday and not as good as you’ll be tomorrow.

In real terms, CQI means:

- You’re not just putting out fires; you’re fireproofing the whole building.

- Your processes get smoother than a freshly waxed bowling lane.

- Your customers stop complaining about the same old problems because—plot twist—you’ve fixed them.

Want to see what this looks like in practice?

Five Features of Continuous Quality Improvement

If you think these features are just another corporate checklist to ignore, like those “mandatory” office birthday celebrations, think again. These building blocks separate the “we’re trying to improve” crowd from the all-stars.

1. Continuous Monitoring and Analysis

You know that friend who obsessively tracks every step, calorie, and REM cycle like their life depends on it? That’s what your business does now. But instead of counting steps, you’re tracking processes with the precision of a detective on the trail of their prime suspect. This helps you catch trends before they have the chance to morph into full-blown problems. And forget basing decisions on Janet from marketing’s “gut feeling”—you’re running on cold, hard facts.

2. Employee Involvement

This isn’t your grandma’s suggestion box. This is a full-on, small-town-gossip-level engagement where everyone’s voice matters, and the whole team’s in the loop. Employees aren’t just whispering ideas in secret. They’re throwing them out confidently, knowing no one’s ready to shoot them down. They’re taking ownership like they just made their first big car purchase—invested and proud. Believe it or not, they care about improving things.

3. Methods and Tools

Implementing CQI effectively requires the right tools and frameworks, ensuring sustainable and data-driven process improvements. You need tools that work. Tools that are simple, effective, and useful enough that they don’t just sit around looking impressive. These are tools like process mapping that make sense, statistical analysis that doesn’t make your head spin, and documentation that people want to use. Fancy is fine, but functional is better.

4. Error Prevention and Quality Control

Forget pointing fingers faster than your siblings during a family fight. This feature makes sure mistakes are caught before they even happen, saving you the hassle of a blame game. Systems get built so solidly that messing up is harder than doing things right the first time. And when errors pop up, it’s a learning moment, not a bus-throwing event. Everyone improves together, and nobody’s left ducking for cover. Understanding the distinction between quality assurance and quality control helps businesses set clear objectives in their CQI efforts.

5. Measurement and Evaluation

If you’re not measuring it, you’re basically guessing—like trying to bake a cake without measuring cups. Measurement and evaluation are core to CQI and quality management, ensuring that improvements are consistently tracked and refined over time.

CQI keeps you out of the guessing game with clear, meaningful metrics. Regular checkups keep progress on track, and feedback loops ensure nothing disappears into the abyss. It’s a system that shows you how far you’ve come and where you need to go next.

Seeing CQI in action can provide clarity. Here are some continuous quality improvement examples across different industries:

- Healthcare: The Chang Gung Medical Center in Taiwan reduced patient wait times by 56% by implementing a feedback loop through patient surveys and staff adjustments.

- Manufacturing: A food factory adopted lean manufacturing tools to lower food product return rates by 89.2%.

- Fashion: The Bangladeshi garment industry increased overall equipment effectiveness by 3–4% by reducing sewing defects and enhancing productivity using the PDCA approach, a continuous quality improvement tool. Each of these examples highlights how continuous improvement drives real, measurable results.

Tired of your improvement efforts feeling like random shots in the dark? SweetProcess gives you the structure to turn those scattered efforts into exciting progress.

Why Is Continuous Quality Improvement Important for a Business?

The benefits of CQI extend beyond operational efficiency because they directly impact profitability, employee morale, and customer satisfaction. Continuous quality improvement (CQI) has been shown to enhance operational efficiency across various industries. For instance, a scoping review in the healthcare sector highlights that CQI initiatives lead to improvements in system performance and patient outcomes.

Additionally, a study on lean manufacturing reports that companies implementing such practices have achieved significant reductions in cycle times and lead times, contributing to overall operational efficiency.

If you’re not implementing CQI, you’re basically leaving money on the table like a rookie poker player at a Vegas casino. CQI forms the backbone of quality improvement initiatives, leading to increased efficiency and enhanced customer satisfaction. So, what are the benefits of CQI? Let’s see:

1. Increased Efficiency

Think of that friend who finally reorganized their kitchen. Suddenly, cooking wasn’t chaos, and they weren’t cursing at cluttered drawers. That’s what CQI does for your business. It’s like decluttering inefficiencies and sharpening every tool in your arsenal.

You’re cutting waste with surgical precision, squeezing more productivity out of the day without burning your team out. And you’re creating workflows that glide effortlessly like that first smooth sip of your favorite juice. Plus, CQI doesn’t require endless meetings or dull reports. It’s the quiet revolution that makes everything just…work.

2. Enhanced Customer Satisfaction

Imagine your customers raving about your business like a teenager screaming at their first concert. That’s another thing CQI can do for your business: enabling you to tackle issues before they snowball into complaints. So your service becomes as reliable and comforting as your mom’s famous meatloaf. When you consistently listen to your customers and act on their feedback, they notice. While this might seem obvious, it’s surprisingly rare in practice. That’s why implementing CQI is so powerful—it creates loyal customers who not only keep coming back but also become advocates for your business.

3. Error Reduction

Stop treating business mistakes like a never-ending game of whack-a-mole. When you adopt CQI, you get tools that act like a vigilant helicopter parent, catching errors before they can trip you up. Quality assurance plays a key role in this process, ensuring that potential issues are identified and addressed proactively.

You become good at creating solid processes that even the clumsiest mishaps struggle to break through. Fixing the same problems over and over isn’t just frustrating—it’s expensive. CQI, combined with quality assurance, saves you from that endless cycle, putting your time and money where it matters: growth, not damage control.

4. Competitive Advantage

While your competitors cling to the “we’ve always done it this way” mindset (a.k.a. the dinosaur approach), you’re busy evolving. With CQI, you’re adapting faster than a chameleon at a disco. You are shifting gears, staying sharp, and keeping pace with every market twist. Innovation isn’t just something you talk about; it’s part of your DNA, setting you apart while others scramble to catch up. Instead of trailing behind, you’re the one leading the charge, leaving the competition wondering how you keep pulling ahead.

5. Long-Term Sustainability

This isn’t some quick-fix fad like that diet you ditched after barely a month. When you embrace CQI, you are committing to playing the long game. You are building systems that outlast trends and stick around longer. You are assembling the tools to craft resilience so strong it rivals your Monday morning coffee, keeping your business steady even when things get chaotic. And yes, it even means planning for the future. While others scramble for Band-Aid solutions, you’re laying the foundation for growth that actually lasts.

6. Improved Accountability

With CQI, everyone knows exactly who owns what. No finger-pointing is necessary. Results become crystal clear and easy to track (no advanced degree required), and accountability actually becomes part of the culture. Shocking, right? Suddenly, people step up and take responsibility, and business starts running smoothly. It’s less chaos, more clarity, and fewer blame games.

7. Improved Staff Morale

Have you ever seen a team more miserable than a cat in a bathtub? That’s what happens when people feel stuck in broken processes. CQI turns this around by giving your team the power to make changes. When employees can flag issues and see their suggestions turn into real improvements, they go from “another day in paradise” eye-rolls to actually giving a damn. It’s like giving someone the TV remote after they’ve been stuck watching infomercials for years.

8. Refined Service Delivery Process

Think of your service delivery like a restaurant kitchen during rush hour. Without CQI, it’s chaos. Orders are getting mixed up, food is getting cold, and everyone is yelling like they’re auditioning for Ramsay’s Hell’s Kitchen. With CQI, you’re running that kitchen like a well-oiled machine. Every step is choreographed, everyone knows their role, and your customers get their “order” exactly how they want it when they want it. No more “sorry for the wait” or “we’ll do better next time” empty promises.

9. Flexibility to Meet Service Need Changes

Markets change faster than fashion trends on TikTok, and if you’re not flexible, you’re basically the business equivalent of dinosaurs watching that meteor approach. CQI builds flexibility into your DNA. When a customer requests a change, you’re not left scrambling to keep up. Instead, you’re already ahead, continuously refining and adapting your processes. Your goal is to endure change and move through it smoothly and confidently, like a pro surfer riding the waves.

10. Enhances Information Management, Client Tracking & Documentation

Most businesses messily handle their information. It’s everywhere, and nobody’s happy about cleaning it up. CQI transforms your information management from “Where the heck is that file?” to “Found it in two clicks.” You’re tracking client interactions better than a stalker with a spreadsheet addiction, and your documentation is so clear that even your intern’s intern could figure it out.

11. Means to Determine & Tracks Program Integrity and Effectiveness

Stop playing pin the tail on the donkey with your program evaluation. CQI gives you actual metrics to track success, not only the vanity metrics that make you feel good but the real, meaty data that tells you if your programs are doing what they’re supposed to. It’s the GPS for your business goals. Use it to head in the right direction.

12. Lends Itself to the Design of New Programs & Program Components

Innovation is more than having random “eureka” moments in the shower. With CQI, you’re building a systematic approach to creating and launching new programs that actually work. It’s like having a test kitchen where you can experiment with new recipes before serving them to customers. You’ll know what works, what doesn’t, and why before you bet the farm on it.

13. Allows Creative/Innovative Solutions

Here’s where the magic happens. When you’ve got CQI running smoothly, your team starts thinking outside the box so much that the box becomes irrelevant. You will realize that beyond solving problems, you’re preventing them from happening in the first place. It’s like having a crystal ball for business problems, except it’s actually based on data and experience instead of some mystical promises no one really understands.

Businesses using SweetProcess report a 30% improvement in efficiency within the first three months. See what structured processes can do for your team. Simplify your processes now—start for free.

How to Streamline Your Company’s CQI Process Using SweetProcess

You’ve got all these fantastic CQI ideas swimming around in your head like a goldfish in a bowl, but without the right tools, they’re about as useful as a chocolate teapot. Let us show you how SweetProcess turns those ideas into reality faster than your IT department’s coffee consumption.

But before then, learn from the sweet experience of Thimbleberry Financial:

Thimbleberry Financial, a financial planning and wealth management firm in Portland, Oregon, faced challenges with employee onboarding and process documentation. Initially, President and Financial Advisor Amy Walls documented procedures using Microsoft Word, but team members found these documents hard to follow, leading to inconsistent task execution. The situation worsened with staff turnover, as the lack of clear, accessible procedures hindered efficient onboarding and task management.

Upon her business coach’s recommendation, Amy adopted SweetProcess, a workflow documentation software. This transition allowed Thimbleberry Financial to:

- Enhance Employee Onboarding and Training: New hires experienced a more organized onboarding process, gaining access to clear, step-by-step procedures from day one.

- Improve Documentation: The team identified and addressed gaps in their existing processes, creating comprehensive and interconnected procedures that were easy to reference.

- Facilitate Seamless Collaboration: With centralized and accessible documentation, team members could efficiently collaborate and cover for each other when necessary.

Implementing SweetProcess streamlined Thimbleberry Financial’s operations, leading to a more efficient team capable of delivering consistent and high-quality services to their clients.

Here’s how SweetProcess can help your business establish a continuous quality improvement culture:

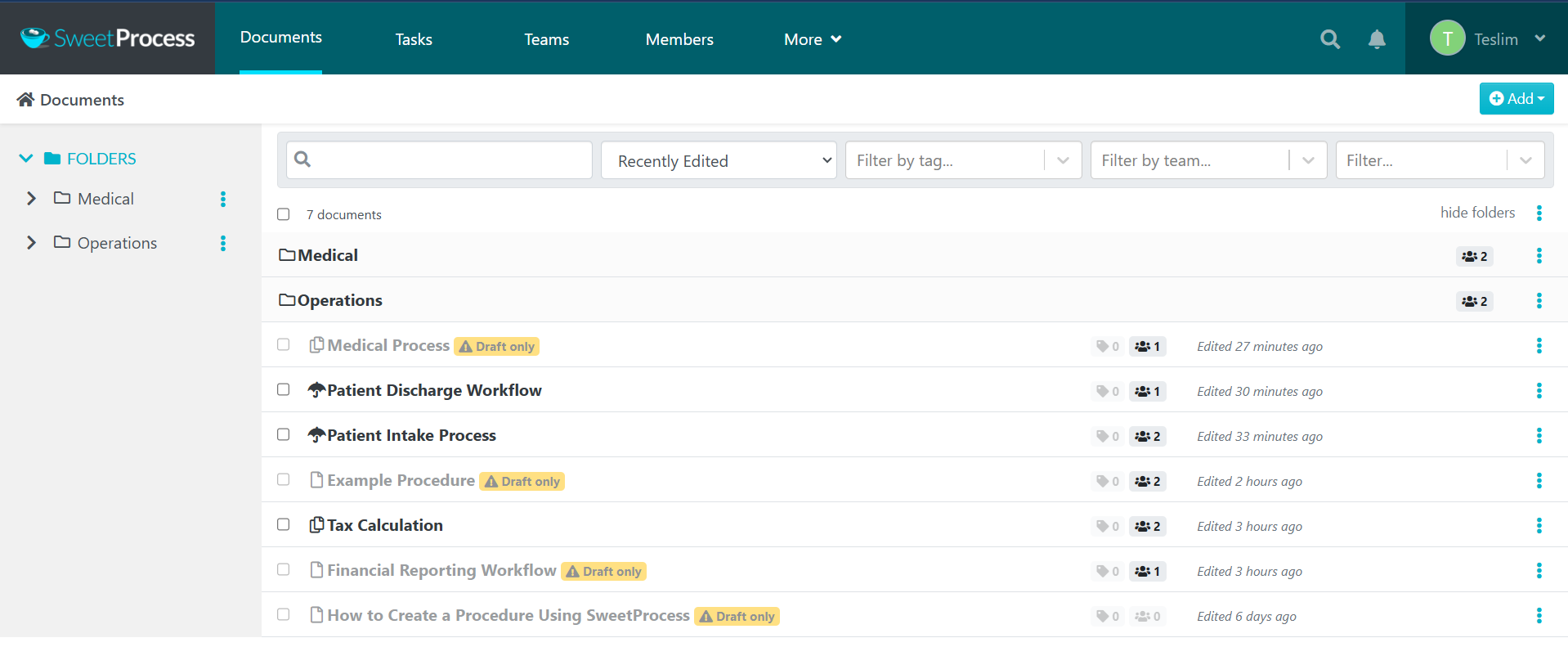

Document Repetitive Tasks in One Place

Remember playing telephone as a kid, where the message got more twisted than a pretzel by the end? That’s your process without proper documentation. Here’s how SweetProcess fixes this:

- Centralized Documentation Hub: Everything lives in one place, searchable and organized. No more “Oh, that process? Yeah, Jim knew it, but he left for Tahiti last month.”

- Step-by-Step Guides: Create crystal-clear instructions that even your most “technically challenged” team member can follow, complete with screenshots, videos, and annotations that make Wikipedia look amateur.

A well-documented quality management system ensures that continuous improvement processes are standardized across the organization.

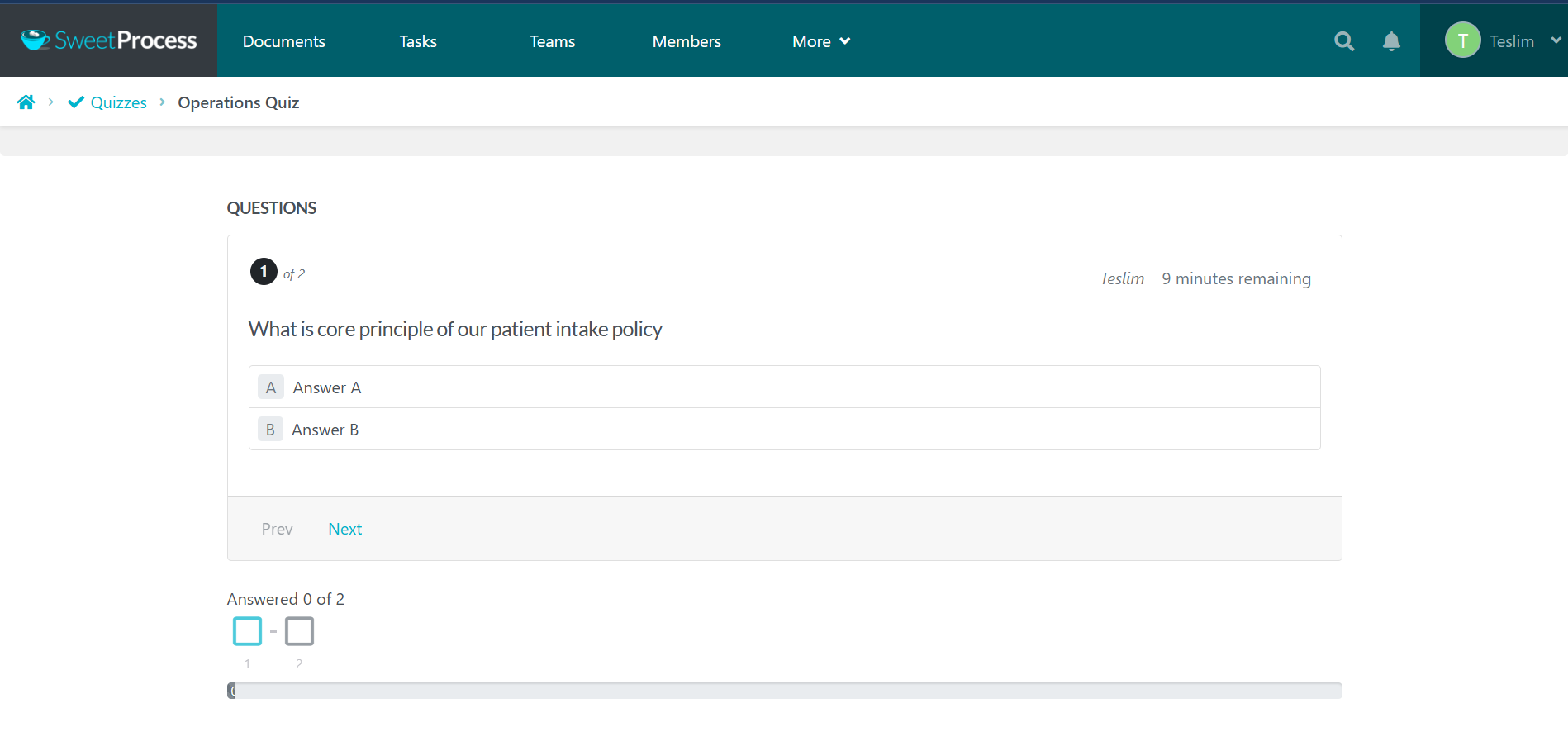

Build a Quiz to Assess Your Team’s Grasp of Company Policies

Do you want to know if your team understands your processes, or are they just nodding along like bobbleheads? SweetProcess has you covered:

- Custom Quiz Creation: Build assessments that actually test knowledge, not just memory.

- Automatic Tracking: See who’s mastering the material and who’s still thinking CQI stands for “Cute Quokka Images.”

- Performance Analytics: Get real data on where your team needs help, not just gut feelings.

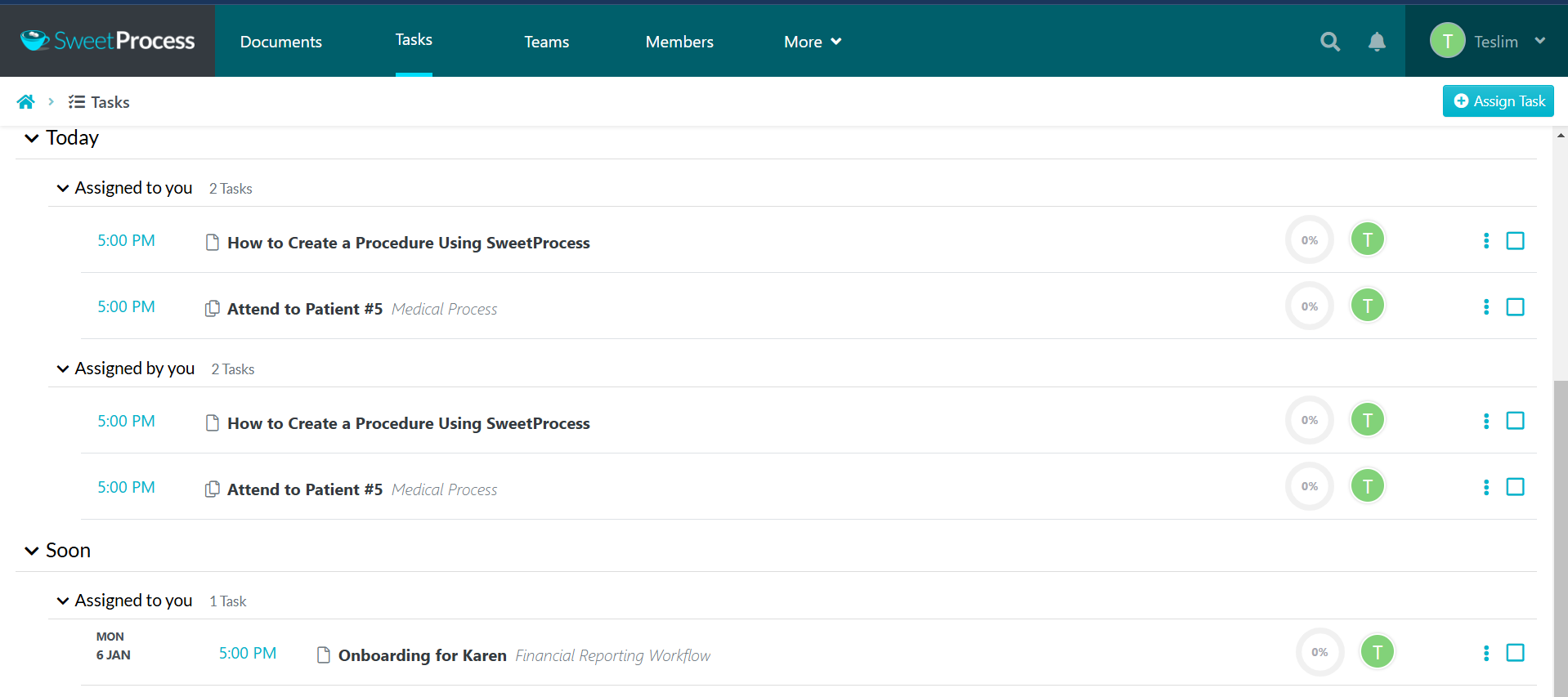

Turn Procedures and Processes Into Actionable Tasks

Here’s a real-world example from Thimbleberry Financial:

Amy Walls, president and financial advisor at Thimbleberry Financial, emphasized the importance of clear documentation in task management:

“I was reluctant. I didn’t think [our procedure] was broken, but once I got in [SweetProcess] and I started plugging in what we had in our Word document, I was like, okay, this is actually smooth. I can easily reference things.”

This highlights how transitioning to an efficient documentation system can streamline task management and improve overall workflow. SweetProcess eases:

- Task Assignment: Delegate with precision, not prayer.

- Progress Tracking: Watch tasks move from “Assigned ” to “Checked” in real time.

- In-Built Accountability: No more “I thought someone else was doing that” excuses.

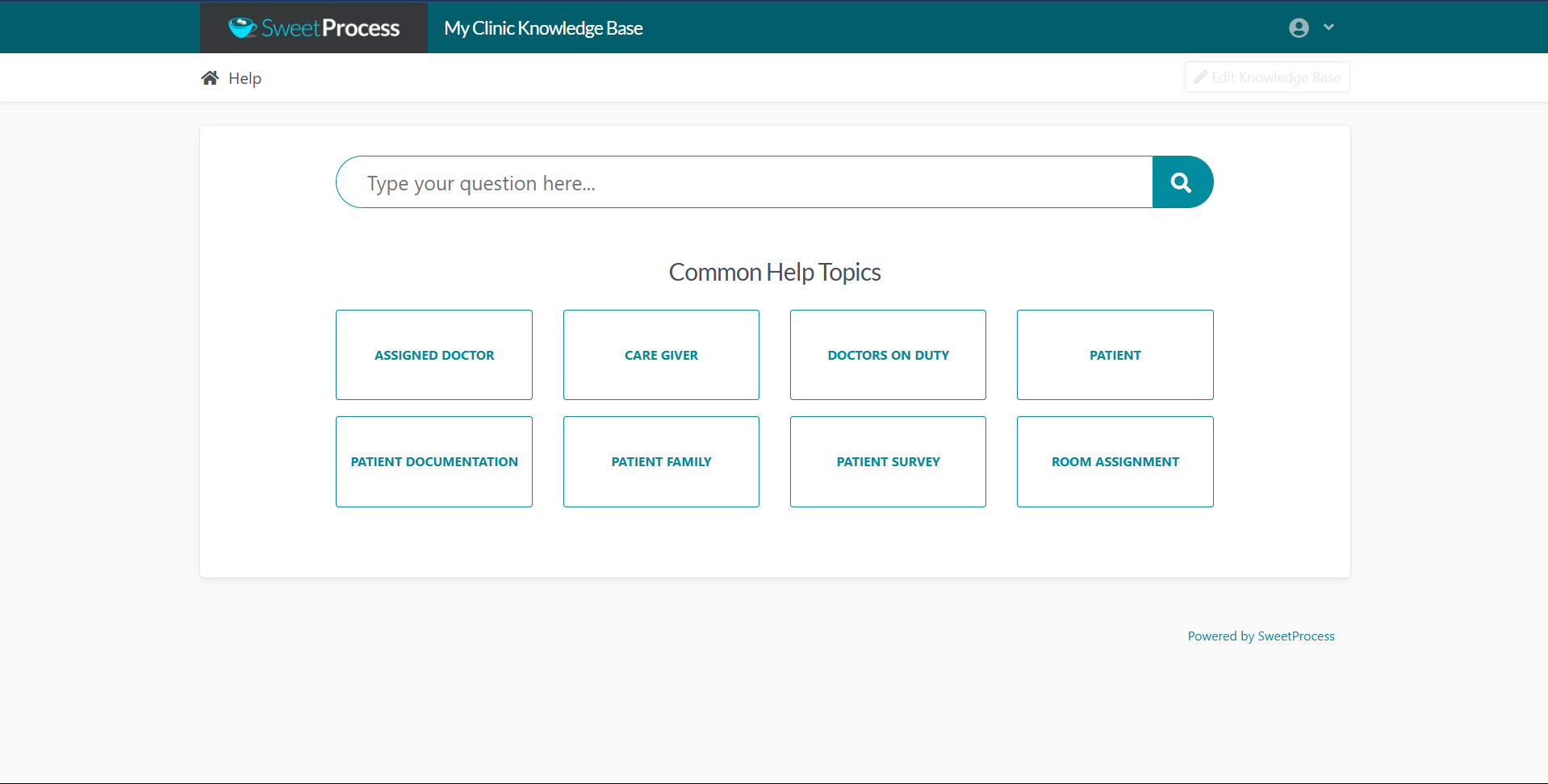

Turn Existing Procedures and Policies Into a Beautiful Knowledge Base

IMS ExpertServices used the SweetProcess knowledge base feature to close employee knowledge gaps:

IMS ExpertServices, serving top US law firms, dealt with employee knowledge gaps and inefficient manual documentation. Process Improvement Leader Mary Pittman introduced SweetProcess, leading to centralized documentation, enhanced accountability, and streamlined operations.

“I ended up going with SweetProcess because, beyond the shadow of a doubt, I knew that I could drop it in the hands of any IMS employee and they would be able to, to any degree, figure out how to use the program.”

Manage Procedures, Processes, and Policies

Optiable uses SweetProcess to boost performance and productivity in managing procedures, processes, and policies for clients:

Optiable, specializing in document management software for law firms, faced inefficiencies due to manual process documentation and micromanagement. CEO Craig Bayer adopted SweetProcess, resulting in improved performance, increased productivity, and reduced micromanagement.

“We immediately started creating processes there… It was pretty instantaneous,”

says Craig

With SweetProcess, Optiable employees enjoy:

- Version Control: Track changes like a hawk watching its prey.

- Access Management: Control who sees what, because not everyone needs to know the secret sauce recipe.

- Real-Time Updates: Changes roll out faster than office gossip.

6 Steps in Continuous Quality Improvement (CQI)

Continuous quality improvement isn’t the same thing as quick fixes or duct-taping problems together until they (inevitably) fall apart again. It’s a mindset. One that turns “good enough” into “can’t stop, won’t stop improving.” Following the six steps below helps you build a business that runs smoother, faster, and smarter. And the best part? It’s a cycle that keeps paying dividends every time you go through it.

Understanding the broader quality improvement process before tackling the six steps can help frame how CQI fits into larger operational goals.

Step 1: Identify the Problem and Develop a Problem Statement

Don’t be that manager who hurls random solutions at problems like confetti at a wedding. Before fixing any problem, clearly identify what’s broken through concrete evidence, not just gut feelings. Vague statements like “Things are slow” don’t help—it’s like telling a mechanic, “My car feels weird.” Instead, gather specific data that proves the problem is real and worth addressing.”

Some companies assume that their issue is “bad customer service.” After months of Band-Aid solutions, they finally realize the root problem is a clunky onboarding process that frustrates customers from day one. They waste time and resources fixing the wrong thing. Don’t be one of those companies.

Step 2: Define the Current Situation

Now it’s detective time—grab your metaphorical magnifying glass and start mapping out what’s happening right now and not what you wish was happening. Document everything: flaws, inefficiencies, and awkward workarounds. Get those baseline metrics like you’re collecting rare Pokémon.

Step 3: Analyze the Problem

This is the step where most people fumble hard. Analyzing the problem isn’t about assumptions or gut feelings. It’s about digging into real data like you’re an archaeologist about to hit pay dirt. Take Colombina as an example: After analyzing their challenges systematically, they achieved a 13.8% increase in overall production efficiency, among other quality improvements. The lesson? Look for patterns and recurring issues in your processes. When you spot the same problem appearing repeatedly, you’ve found your priority to address.

Step 4: Develop an Action Plan

Now things get exciting. Building an action plan is like crafting the blueprint for success. Except you’re aiming for grandma’s-secret-recipe level specificity. By using an action plan template or writing one from scratch, you should clearly define who owns each part (no more “somebody should do it” vibes), and set deadlines that actually mean something. Accountability is key. Without it, even the best plans can fall apart.

Step 5: Look at the Results

Time to crunch the numbers and see if your efforts paid off. Did your changes actually move the needle, or did you just shuffle the deck chairs around? Compare your results before and after like a classic gym enthusiast. Document both the wins and the flops because even the missteps are valuable learning moments.

Step 6: Start Over

Surprise! CQI isn’t a one-and-done deal. It’s more circular than a hamster wheel but way more productive. Take what you learned, find the next weak link, and keep going. Improvement is the engine that keeps your business humming like a cat that just had a bowl of cream. Keep running the cycle, and soon enough, your processes will run like a well-oiled machine.

Want to make these steps actually work instead of just being another PowerPoint presentation? Jump on SweetProcess and turn theory into practice for free. Your team will thank you for not making them use another spreadsheet that crashes every other Tuesday.

Tools to Perform Continuous Quality Improvement (CQI)

Continuous quality improvement tools are like a Swiss Army knife for your business, streamlining processes and eliminating inefficiencies at every level. These tools are the heavy hitters that can streamline, refine, and supercharge your processes. Each one has its specialty, and when used right, they turn inefficiencies into smooth-running operations.

Popular continuous quality improvement tools include Six Sigma, PDCA, and lean principles, all designed to refine business operations and ensure sustainable growth. Let’s break them down in a way that actually makes sense (and maybe even makes you chuckle).

1. Lean Principles for Operational Efficiency

Lean is basically Marie Kondo-style minimalism for your business. It’s all about cutting the fluff, streamlining the flow, and focusing on what actually matters, i.e., creating value. Anything that doesn’t contribute to customer satisfaction? Out it goes. When you adopt the lean approach, the following is what you do:

- Eliminate waste faster than a teenager clears their browser history.

- If it doesn’t help the customer, it’s clutter. Get rid of it.

- Keep things flowing smoother than your Sunday morning playlist.

Have you ever wondered why Toyota’s manufacturing runs like clockwork while others struggle to keep up? Lean is their secret sauce. They trim waste so effectively that their production lines make fast-food drive-thrus look sluggish. The result? Fewer delays, lower costs, and satisfied customers. Learn more about lean principles from the EPA.

2. Baldrige Quality Award

This is not your typical “everyone gets a trophy” award. Baldrige is more like the Olympics of quality management. It is reserved for businesses that work and see serious results. The Baldrige method:

- Forces you to look at your business from top to bottom with no room for shortcuts.

- Covers leadership, strategy, workforce, customers, and results.

- Makes you examine your operations like a CSI investigator looking for clues.

Fun Fact: Companies using Baldrige criteria consistently outperform the S&P 500 by large margins. That’s years of domination. It’s the difference between jogging a local 5K and qualifying for the Boston Marathon.

3. Six Sigma Model

Forget the fancy name. This model has a process called DMAIC (define, measure, analyze, improve, control). It’s more like detective work for your business processes. So, with this tool, you’re not guessing at problems. There’s never room for that under this method. You’re breaking them down scientifically and fixing them for good. And this is how it works. You:

- Define what’s not working.

- Measure just how broken it is.

- Analyze the root cause.

- Improve it until the issue is history.

- Control the process so it doesn’t unravel again.

Think of Six Sigma like running CSI on your operations. Every problem gets dissected with laser precision. No throwing spaghetti-on-the-wall-to-see-which-one-sticks kind of solutions allowed. Explore the Six Sigma model in-depth now.

Also, Six Sigma helped a Thai hospital improve the dispensing process performance, resulting in dispensing error reduction and improved patient safety by 66.66%. This is just one of many continuous quality improvement examples showcasing the effectiveness of these tools in action.

4. Total Quality Management (TQM)

Quality is everyone’s responsibility. TQM focuses on involving the entire organization in quality improvements and fostering a culture where every employee plays a role in enhancing outcomes. From the top brass to the interns, everyone plays a role in improving processes. In other words, it is the ultimate team effort.

- Customer focus is sharper than a ninja’s blade. Feedback from customers becomes the driver of internal change.

- Everyone is part of the quality movement. Yes, even Bob from accounting. Talk of cross-departmental collaboration.

- Continuous improvement becomes the rhythm of your business, not a one-time thing.

When TQM is done right, quality becomes second nature, and customer satisfaction skyrockets. It’s not a “one department” job. It’s the company’s heartbeat.

5. The PDCA Cycle

Plan-do-check-act (PDCA) is the hamster wheel of progress, except this one actually gets you somewhere, not where you started from, though. It is the classic improvement cycle. It’s a simple iterative process, and perfect for tackling small problems before they grow into big ones. It is a four-step process:

- Plan: Set goals and determine the actions needed to achieve the goals. (And no, “winging it” doesn’t count.)

- Do: Test it out on a small scale first, and document your findings while you are at it.

- Check: Did it work, or did you accidentally create a new headache? Analyze your findings and document what you learned in the previous step.

- Act: Roll out the winning solution, or head back to the drawing board depending on the results from the previous steps.

PDCA might seem basic, but it’s one of the most effective tools for continuous quality improvement. It is structured yet flexible problem-solving. It keeps businesses nimble, constantly tweaking and evolving.

Tired of drowning in quality improvement tools with no clue where to start? SweetProcess helps you turn these strategies into real-world solutions without the chaos. Organize Your Operations Today—Free Trial.

Continuous Quality Improvement in Healthcare: How to Implement It

Implementing continuous improvement in healthcare isn’t like optimizing your local coffee shop’s latte production. In healthcare, continuous improvement focuses on enhancing patient outcomes, increasing operational efficiency, and minimizing errors—areas where the stakes are much higher than a medical bill without insurance. This is one of the most critical sectors for continuous quality improvement. Mistakes and inefficiencies cost more than money. They can cost lives. Implementing CQI in healthcare ensures patient safety, improves outcomes, and streamlines operations.

Why CQI Is Different in Healthcare

Healthcare is its own beast. According to the National Library of Medicine, 10–20% of gain in health outcomes is a result of continuous improvement in healthcare.

While other industries worry about profit margins and customer satisfaction, you’re juggling lives, regulations, Henry from maintenance, and Bob from accounting all at once. You’ve got:

Patient Lives on the Line: Every decision you make has real consequences. When Amazon messes up, someone gets the wrong color socks. When healthcare messes up…well, let’s just say it’s a bit more serious than mismatched footwear. That’s why your CQI program needs to be tighter than airport security.

Regulation Central: If you think the DMV has a lot of rules, healthcare regulations will make your head spin faster than a centrifuge. You’re dealing with HIPAA, Joint Commission, CMS, and enough acronyms to make alphabet soup jealous. Your CQI program needs to dance with all these regulations without stepping on any toes.

Stakeholder City: You’ve got more stakeholders than a vampire convention: patients, doctors, nurses, administrators, insurance companies, regulatory bodies, and that one board member who still thinks emails are witchcraft. Each group has its own needs, wants, and “absolute must-haves.”

Now let’s look at the three steps to install continuous quality improvement in healthcare:

Step 1: Build Your Dream Team

This isn’t your average office task force. You need a quality squad that makes the Avengers look disorganized.

Clinical staff members are your front-line warriors. They’re the ones who know the difference between how things look on paper and how they work in real life. Get your nurses, doctors, and technicians involved—they’ll tell you where the real problems are, not just where the spreadsheet says they should be.

Your administrative professionals make the hospital run while everyone else is saving lives. They understand budgets, schedules, and how to make things happen without violating sixteen different regulations. Plus, they know where all the good snacks are hidden.

Patient advocates represent the whole reason we’re here. Get people who eat, sleep, and breathe patient experience. They’re your reality check when someone suggests a “brilliant” idea that would make patients more miserable than an MRI machine playing Justin Bieber.

The data analysts on your team can turn mountains of numbers into actual insights. These folks can spot trends like a radiologist spots fractures. They’re the ones who’ll tell you if your improvements are actually, you know, improving things.

Step 2: Focus on Patient-Centered Care

If you think your patients are just numbers on a spreadsheet, you’re in the wrong business. Let’s focus on what truly matters for patient care.

Start by tracking patient satisfaction as if your career depends on it—because it does. The days of winning patients over with a lollipop and a smile are long gone. You need to monitor satisfaction scores with the dedication of a food critic chasing Michelin stars. Develop meaningful surveys that provide actionable insights, not just simplified emoji-based pain scales.

Keep a close eye on readmission rates, too. Nobody wants to see patients coming back like they’ve got a hospital loyalty card. Track those readmissions and figure out why Mrs. Johnson is back for the third time this month. Is it because of your discharge process or because she loves the hospital pudding that much? (Spoiler: It’s probably not the pudding.)

Then there’s the HCAHPS scores—think of them as Yelp reviews with real consequences. These scores measure patient satisfaction with their hospital experience, and you’ll want to keep them higher than your coffee consumption levels. The key is to genuinely listen to patient feedback, implement improvements based on consistent patterns rather than one-off complaints, and ensure your staff communicates with the clarity of seasoned public speakers.

The HCAHPS survey, formally known as the Hospital Consumer Assessment of Healthcare Providers and Systems, provides a standardized way to evaluate hospital care nationwide. It examines crucial aspects of the patient experience, from how well doctors and nurses communicate to the responsiveness of hospital staff. The survey delves into pain management effectiveness, hospital cleanliness and quietness, and the clarity of discharge information. These results are publicly reported and serve as a benchmark for comparing hospitals across the country, making them an essential metric for any healthcare facility focused on improvement.

Step 3: Data Collection That Doesn’t Make Everyone Want to Quit

In healthcare, the difference between good and exceptional often comes down to what you track—and how you use it. By measuring outcomes, processes, and safety incidents, you’re building a system (beyond ticking boxes) that delivers better patient care, faster recovery, and fewer “oops” moments. You need tracking for the following reasons:

Clinical Outcomes: The Heart of Healthcare Quality

Clinical outcomes are the bread and butter (or the meat and potatoes) of healthcare improvement. This is where the numbers really matter, showing how well patients recover, how often complications arise, and how effective treatments are. These stats should be way more impressive than your fantasy football predictions.

Recovery rates show how fast patients bounce back—hopefully faster than your internet during peak hours. Complication rates should stay lower than your golf score (unless you’re suspiciously good at golf). And when it comes to treatment effectiveness, if it’s not working better than your last attempt to assemble IKEA furniture without the manual, it’s time to rethink it. But collecting data shouldn’t be like hoarding Pokémon cards. The data should tell a compelling story—one that sticks, unlike those compliance training videos you slept through last week.

Process Metrics: Timing Is Everything

Ever wonder if healthcare processes are secretly competing with the DMV for longest wait times? Time to find out. Process metrics shine a light on where things slow down, where resources vanish, and how smoothly everything (or nothing) flows.

Patient wait times need monitoring—if patients are waiting longer than you wait for your food at lunch rush, that needs fixing. Resource efficiency should be better than your teenager “studying” with TikTok open in another tab. And bottlenecks aren’t just in the parking lot or the cafeteria at noon—finding where things jam up and smoothing them out is crucial. Timing everything is important, but making those numbers meaningful and using them to improve experiences on every level matters more.

Safety Incidents: Because “Oops” Isn’t a Metric

Tracking safety incidents is like being a helicopter parent with one eye glued to their kid’s screen time. Every “oops,” “almost oops,” and full-on “oh, no” needs to be logged, analyzed, and turned into an opportunity to improve.

Near-misses are those “almost” moments where disaster was dodged by sheer luck or quick thinking. Actual incidents are those “oh, crud” moments where things didn’t go according to plan (but improvements are in progress). Recovery actions focus not just on how problems were fixed, but more importantly, how to prevent them from happening again.

In healthcare, the difference between good and exceptional often comes down to what you track—and how you use it. Continuous improvement in healthcare relies heavily on data, ensuring patient safety, operational efficiency, and regulatory compliance.

The goal is to prevent people from becoming regular guests, not just to track incidents. Because in healthcare, “almost safe” isn’t safe enough.

Stop letting critical metrics collect dust! SweetProcess helps you turn these insights into action, streamlining clinical quality and boosting patient outcomes without adding more chaos to your day.

Continuous Quality Improvement vs. Lean Process Improvement

You’re probably thinking, “What the hell is the difference? They both sound like corporate buzzwords for making stuff better.” But hang on. There’s some pretty interesting stuff here that could save you from a headache when you’re trying to improve your business.

Think of CQI as your perfectionist friend who’s always looking for ways to make everything just a little bit better all the time. They’re the ones who’ll spend three hours reorganizing their closet because they found a slightly more efficient way to hang their shirts. That’s CQI—it’s all about those small, constant tweaks that add up over time.

Lean process improvement, on the other hand, is like that friend who walks into your kitchen, takes one look at your setup, and goes, “Why the hell do you keep your coffee maker on the other side of the room from your cups?” They’re looking for obvious waste and inefficiencies that they can eliminate right now.

Here’s the real deal on how these two approaches differ:

| Aspect | Continuous Quality Improvement (CQI) | Lean Process Improvement |

| Focus | Incremental, ongoing improvements to processes and services | Eliminating waste to maximize value and efficiency |

| Approach | Systematic, long-term, and organization-wide | Focused on specific areas of inefficiency |

| Scope | Applies to every part of the organization, from admin to production | Often applied to production or service delivery processes |

| Involvement | Employees at all levels contribute to improvements | Primarily driven by managers and project teams |

| Outcome | Better quality, reduced errors, and improved overall performance | Faster, more efficient processes with less resource waste |

| Timeframe | A continuous and never-ending cycle | Project-based with clear start and end points |

| Tools Used | PDCA, Six Sigma, TQM, Baldrige | Value Stream Mapping, Kaizen, 5S, and Just-in-Time |

These approaches aren’t enemies. They’re more like peanut butter and jelly. Sure, they’re different, but they work pretty damn well together. Many smart companies actually use both: lean to eliminate the obvious waste that’s driving everyone nuts and CQI to keep things getting better over the long haul.

The secret sauce?

Don’t get hung up on choosing between them. Instead, think about what your business needs right now. If you’re bleeding efficiency and need quick fixes, go lean. If you’re doing okay but want to keep getting better, CQI might be your jam.

Enhance Your Company’s CQI Process With SweetProcess

We’ve talked about all the fancy theories and processes behind CQI, but the truth is that none of this matters if you can’t actually implement it in your organization without losing your mind (or your staff’s sanity).

Too many companies try to manage their CQI processes using a mess of Google Docs, Excel sheets, and—god forbid—actual paper documents scattered across different departments. It’s like trying to herd cats while blindfolded. In the rain. On a unicycle.

Here’s why SweetProcess is your ticket out of this circus:

First off, it gives you one central place to document everything. No more “Oh, I think Bob from accounting has that procedure document on his laptop, but he’s on vacation in Hawaii.” Everything’s right there, accessible to everyone who needs it when they need it.

It’s not all about storing documents, though. SweetProcess lets you turn your CQI processes into living, breathing systems that actually get used. You can:

- Create step-by-step procedures that don’t look like they were written by a robot

- Track who’s doing what (and who’s actually reading those procedures you spent hours writing)

- Update everything in real time when you find better ways to do things

- Get feedback from your team without having to schedule yet another mind-numbing meeting

Think about it: Every time you implement a new improvement, you can immediately update your documentation. Your team gets notified automatically. No more “Oh, I didn’t know we changed that process three months ago.”

Don’t wait to modernize your operations:

- Sign up for a 14-day free trial of SweetProcess (no credit card required—we’re not those guys)

- Upload your existing procedures (don’t worry, we’ll help you organize them)

- Watch your team actually start using them. Yeah, you heard right.

The bottom line?

CQI doesn’t have to be a pain in the neck. With the right tools, you can turn it from a theoretical concept into something that actually makes your business sweet, day after day.

Don’t let your continuous improvement efforts get derailed by poor documentation and scattered processes. Give SweetProcess a shot right away—your future self will thank you.