Last Updated on May 6, 2025 by Owen McGab Enaohwo

Have you ever felt that your business processes could be more efficient, but you’re unsure where to start or how to approach them?

Does the continuous improvement process suit your industry or team size?

Or you may be questioning how to sustain motivation and commitment to improvement in the long term.

To address these questions, we’ll delve into the essence of continuous improvement, a systematic approach that enhances processes, products, or services through incremental, strategic changes.

You’ll discover a range of tools like SweetProcess and techniques tailored for various scenarios, learn about different continuous improvement models, and gain insights into best practices.

Sign up for a 14-day free trial of SweetProcess. No credit card is required.

Table of Contents

What Is a Continuous Improvement Process (CIP)?

How to Implement Continuous Improvement Process in Your Organization

How to Sustain a Culture of Continuous Process Improvement Using SweetProcess

Benefits of Continuous Improvement Process in Your Business

Tools for Successful Implementation of Continuous Process Improvement

Types of Continuous Improvement Methodologies

Tips for Nurturing a Culture of Continuous Improvement in Your Company

Build a Culture of Continuous Improvement in Your Organization

What Is a Continuous Improvement Process (CIP)?

The continuous improvement process (CIP) is a strategic, ongoing approach to enhance business processes, products, or services.

Unlike project-based improvements that are temporary and focused on specific issues, CIP is a sustained, long-term commitment to incremental change and refinement.

The focus is on making small, continuous changes rather than large-scale, disruptive overhauls. CIP ensures that improvements are:

- Manageable

- Less risky

- More easily integrated into daily operations

Retail giants like Walmart and Target use continuous improvement strategies to optimize their supply chain and inventory management. They continuously analyze sales data, customer feedback, and supply chain logistics to make incremental improvements and changes necessary to increase product availability, reduce waste, and enhance customer shopping experience.

How to Implement Continuous Improvement Process in Your Organization

You should set a culture of embracing the idea that there’s always room for betterment, whether in processes, products, or services.

We’ll guide you through the essential steps to integrate CIP into your organization, ensuring it becomes a natural and continuous part of your team’s mindset and everyday work.

Step 1: Identify challenges and prioritize

The first step is to identify and prioritize the challenges you face. This stage sets the direction for your improvement efforts.

Start by collecting feedback from various sources within your organization—employees, management, customer feedback, and performance data. Encourage open and honest communication about what’s working well and what could be better.

Look at the data and feedback to identify patterns or recurring issues.

The analysis will help you understand the root causes of challenges rather than just addressing the symptoms.

Step 2: Access current processes

Do a deep dive into how things are currently done to understand the baseline from which improvements can be made.

Begin by mapping out your existing business processes. Use flowcharts, diagrams, or process maps.

The goal is to have a visual representation of the steps involved in each process, which helps in identifying inefficiencies or bottlenecks.

Involve the employees who are directly engaged with these processes. They are better placed to know what needs improvement.

With the process maps and performance data, identify areas where the process is less efficient. Look for steps that are time-consuming, error-prone, or unnecessary.

Step 3: Engage stakeholders

Engaging stakeholders ensures that efforts are relevant, well-received, and effectively implemented.

Identify who your stakeholders are. These are your employees at various levels, management, customers, suppliers, and possibly even regulatory bodies.

Then, inform them about the goals of the CIP, the processes under review, and how they can contribute to the improvement efforts.

For instance, employees may need detailed information about how changes affect their daily work. At the same time, customers might be more interested in how these changes will improve product quality or service delivery.

Step 4: Select improvement methodology

The fourth step is selecting an appropriate improvement methodology that aligns with your organization’s needs and goals.

Several methodologies are available for continuous improvement. Some of the most popular include:

- Lean: Focuses on eliminating waste and increasing efficiency

- Six Sigma: Emphasizes reducing variability and defects

- Total Quality Management (TQM): Aims at improving all organizational processes to enhance quality

- Kaizen: Promotes small, ongoing, positive changes

The chosen methodology should match your organization’s culture, size, and industry.

For example, Six Sigma is more suitable for large organizations with complex processes, while Kaizen can be effectively implemented in smaller organizations for quick, incremental improvements.

Step 5: Define goals and metrics

Set specific goals based on the challenges you identified in earlier steps and the chosen improvement methodology.

These goals should be aligned with your organization’s overall objectives.

For example, if the primary aim is to reduce operational costs, a specific goal could be to decrease production expenses by a certain percentage within a set timeframe.

For each goal, identify relevant key performance indicators (KPIs). KPIs are quantifiable metrics that will help you measure progress toward achieving your goals.

For instance, if a goal is to improve customer satisfaction, relevant KPIs include:

- Customer satisfaction scores

- Repeat customer rates

- The number of customer complaints

Ensure everyone involved in the CIP understands the goals and how success will be measured.

Step 6: Develop and document an action plan based on the chosen methodology

Outline specific actions required to achieve objectives from the previous step.

These actions should be directly linked to the principles and tools of the chosen methodology.

For example, if using lean, actions might include streamlining workflow processes or eliminating non-value-added activities.

Clearly assign responsibilities for each action item. Determine who will be responsible for implementing each part of the plan, who will oversee the process, and who will be involved in supporting roles.

For each action item, set realistic timelines. These timelines should consider:

- The complexity of the task

- The availability of resources

- Any dependencies between different tasks

This documentation should include the specific actions, responsible parties, resources required, timelines, and how each action relates to the overall goals.

Step 7: Sustain a continuous improvement culture

Implementing a culture of continuous improvement within your organization is the most challenging step.

The commitment to continuous improvement must start at the top. Leadership should consistently communicate the importance of continuous improvement, demonstrate their commitment through actions, and allocate resources to support these efforts.

Leaders should act as role models, willing to embrace change and learn from failures.

Encourage employees at all levels to contribute ideas and participate in improvement activities.

Also, create channels for feedback and ideas, recognize and reward contributions, and provide training and development opportunities to empower employees.

Step 8: Scale to other areas

Once you have successfully implemented a CIP in one area of your organization and established a culture that embraces it, the next step is to scale these efforts to other areas.

Expanding the scope of continuous improvement ensures that the organization feels the benefits.

Start by thoroughly evaluating the successes of your initial continuous improvement projects. Document what worked well, the challenges encountered, and how they were overcome.

Then look for other areas within your organization that could benefit from a similar approach.

NOTE: Different areas may require different approaches. The methodology and tactics that worked in one area need to be adapted to fit the unique challenges and dynamics of another.

As you scale to new areas, closely monitor the progress and impact of your efforts. Be prepared to make adjustments based on feedback and performance data.

How to Sustain a Culture of Continuous Process Improvement Using SweetProcess

You need the right documentation tools to carry out the continuous improvement process (CIP) efficiently.

Documenting SOPs creates a clear and detailed baseline of how processes are currently performed. This is essential for CIP, as you can’t improve what you haven’t defined.

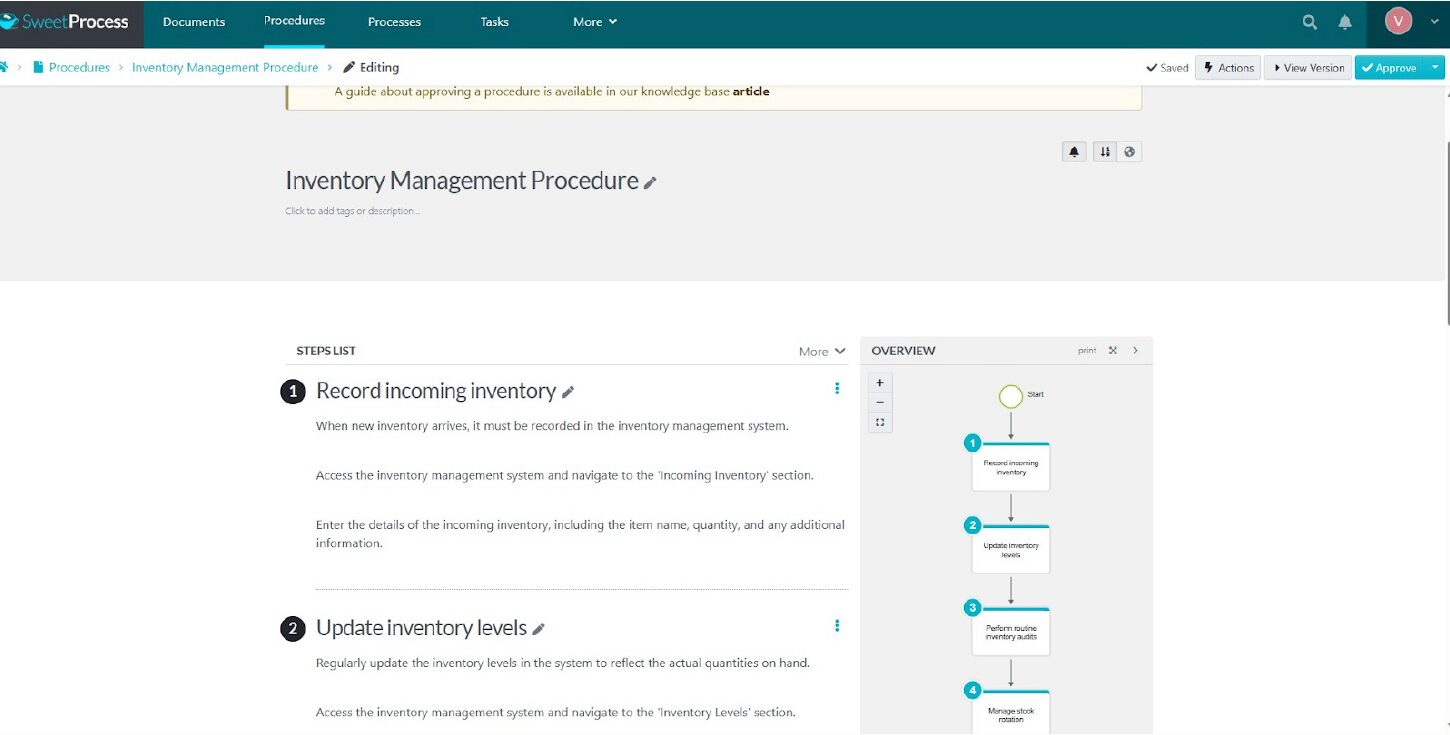

With SweetProcess, you can efficiently document SOPs, collaborate on tasks, track progress, and make data-driven decisions. Here is how to use SweetProcess for CIP:

How to Document and Visualize Processes Using SweetProcess

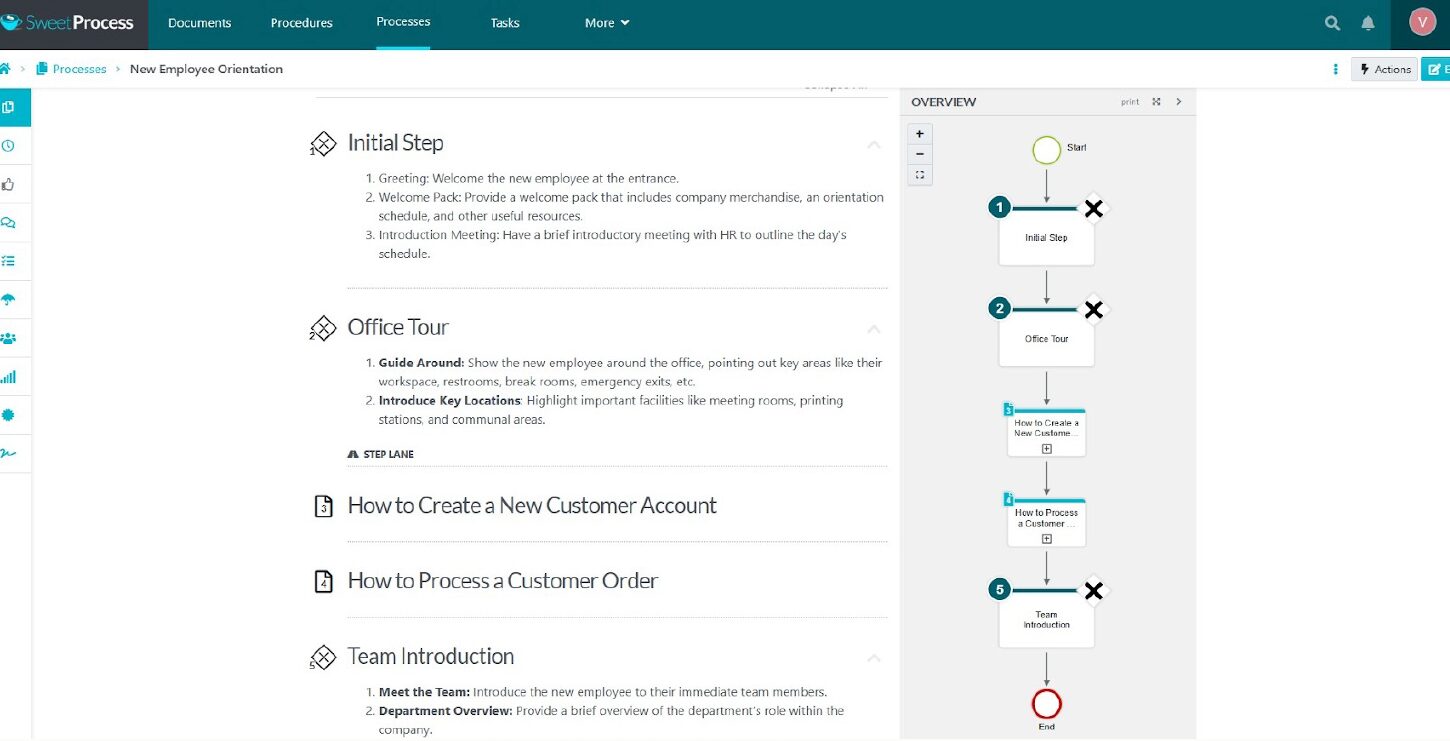

Think of a process as a series of procedures, each contributing to the completion of a larger task.

For example, in a manufacturing setting, product production can be broken down into parts such as procurement of materials, assembly, quality control, and packaging.

Each of these parts can be further divided into more detailed procedures.

Using SweetProcess, you can document and visualize these processes effectively.

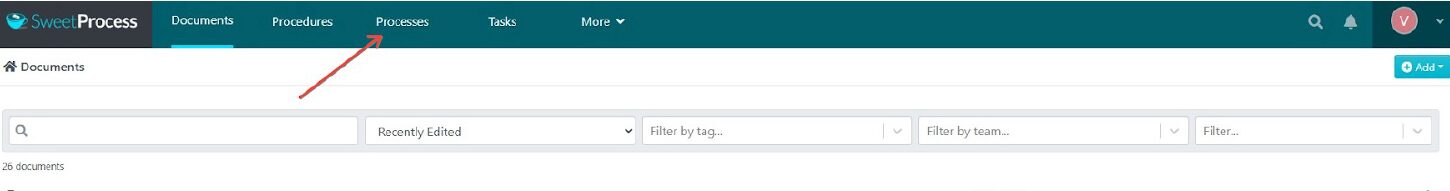

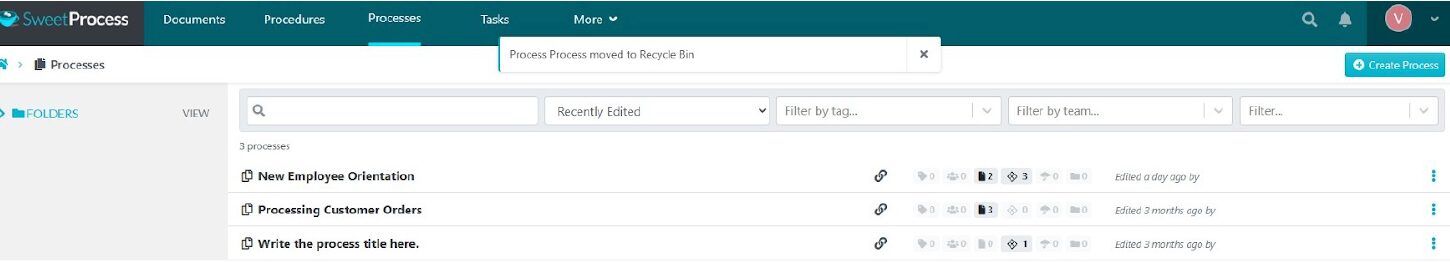

Start by navigating to the “Processes” tab on the SweetProcess platform.

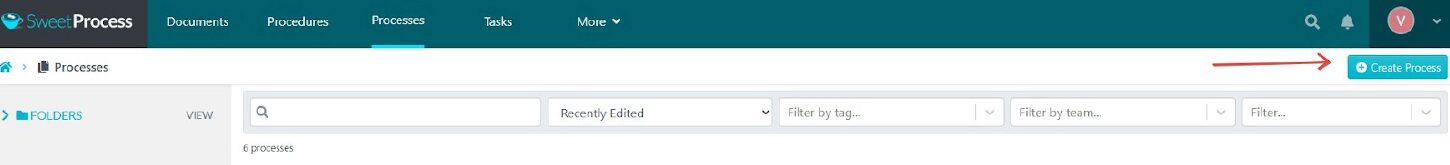

In the top right-hand corner of the page, click on the “Create Process” button. This will initiate the process creation workflow.

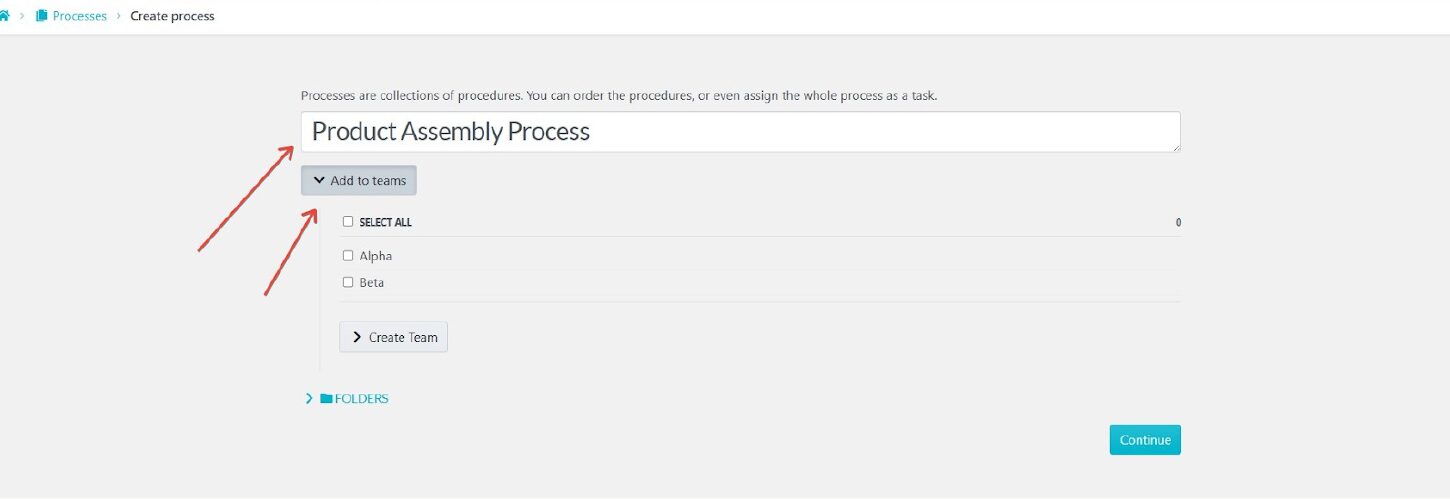

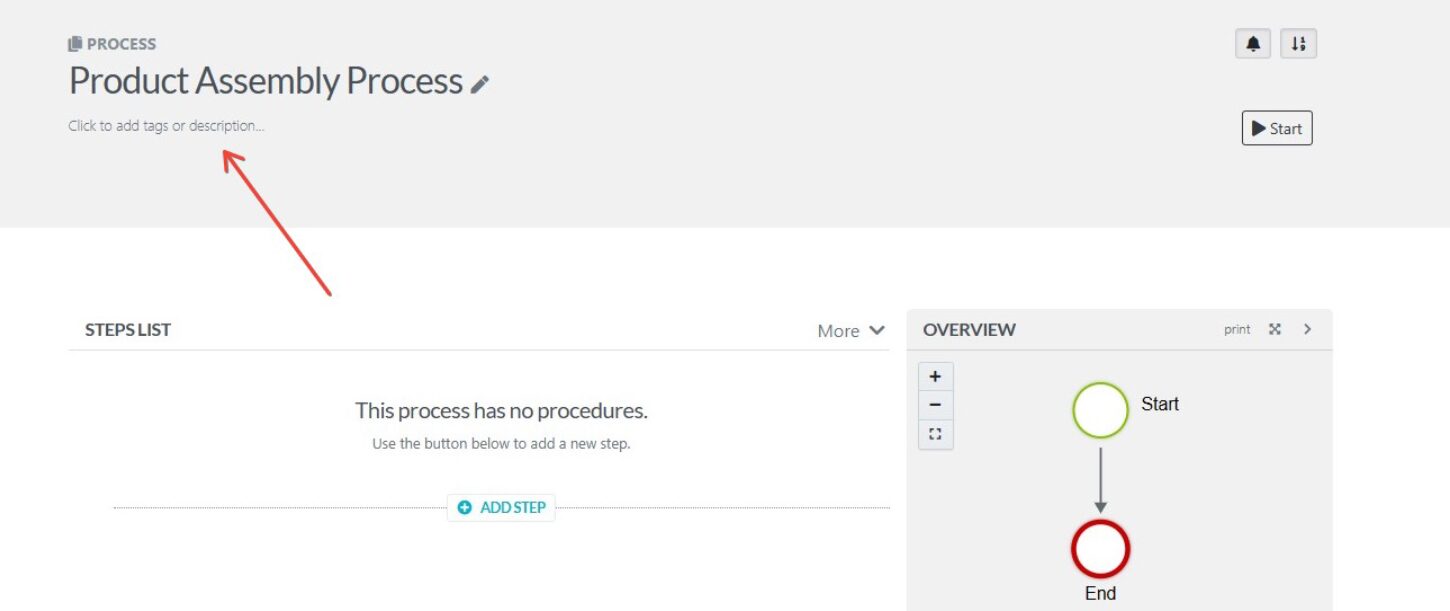

Name your process. For instance, if you’re documenting a manufacturing process, you might title it “Product Assembly Process.”

You can assign the process to specific teams within your organization. Click on the checkboxes to add the process to one or multiple teams simultaneously.

After assigning teams, click the “Continue” button to proceed.

Next, click on the process title to add a detailed description and relevant tags. Tags are important for categorizing and easily retrieving your processes later.

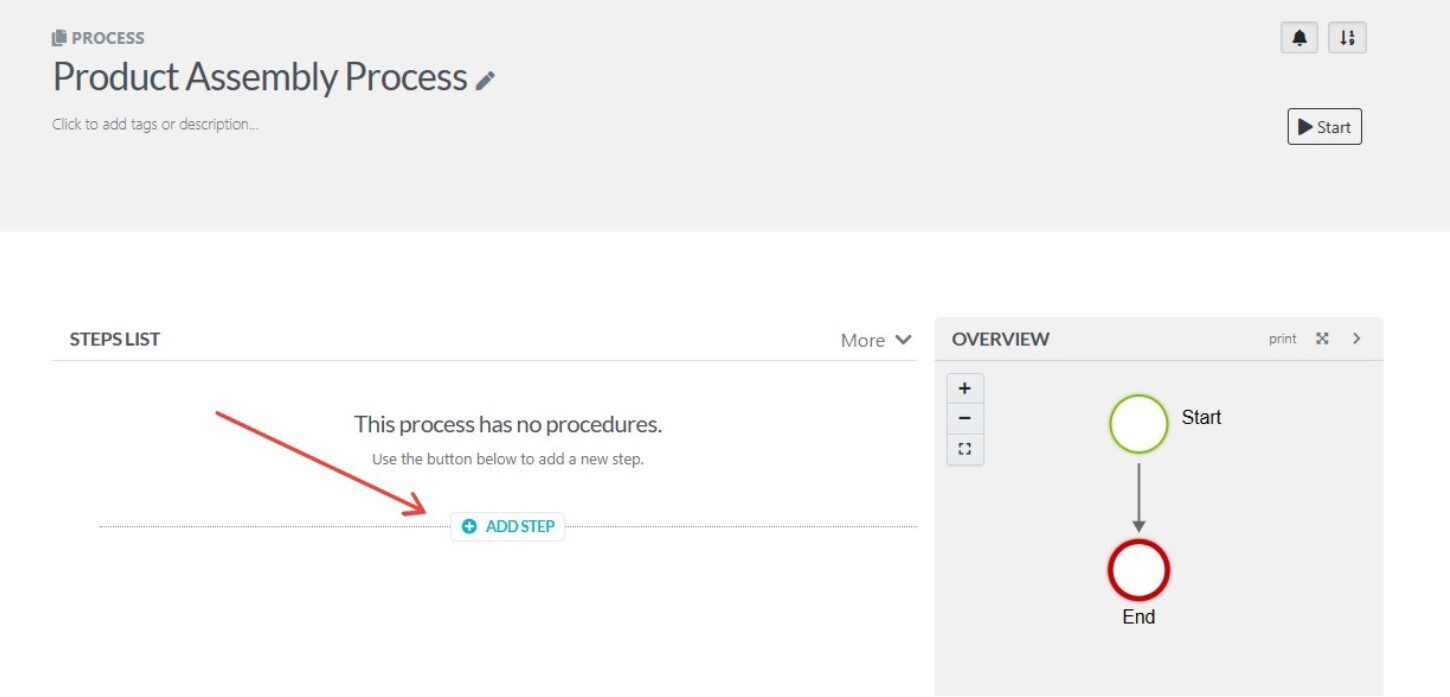

Then add steps to the process. Break down the process into specific stages or steps. For example, in the “Product Assembly Process,” you might have steps like “Material Preparation,” “Assembly Line Start-Up,” “Quality Assurance Check,” etc. Click “Add Step” to include each of these in the process.

Under each step, you can link existing procedures from SweetProcess or create new ones.

Procedures provide detailed instructions for performing specific tasks within a step. For example, you might have a procedure on “Material Preparation.”

Also, include decision points where choices might alter the course of the process based on different scenarios.

After adding all the steps and details, click “Finish Editing” to save your work. Finally, click “Approve” to make the process live and accessible to the relevant teams.

With processes clearly documented in SweetProcess, continuously evaluating and improving them becomes much easier.

Your teams can regularly review each step of a process to identify bottlenecks, inefficiencies, or improvement opportunities for streamlining.

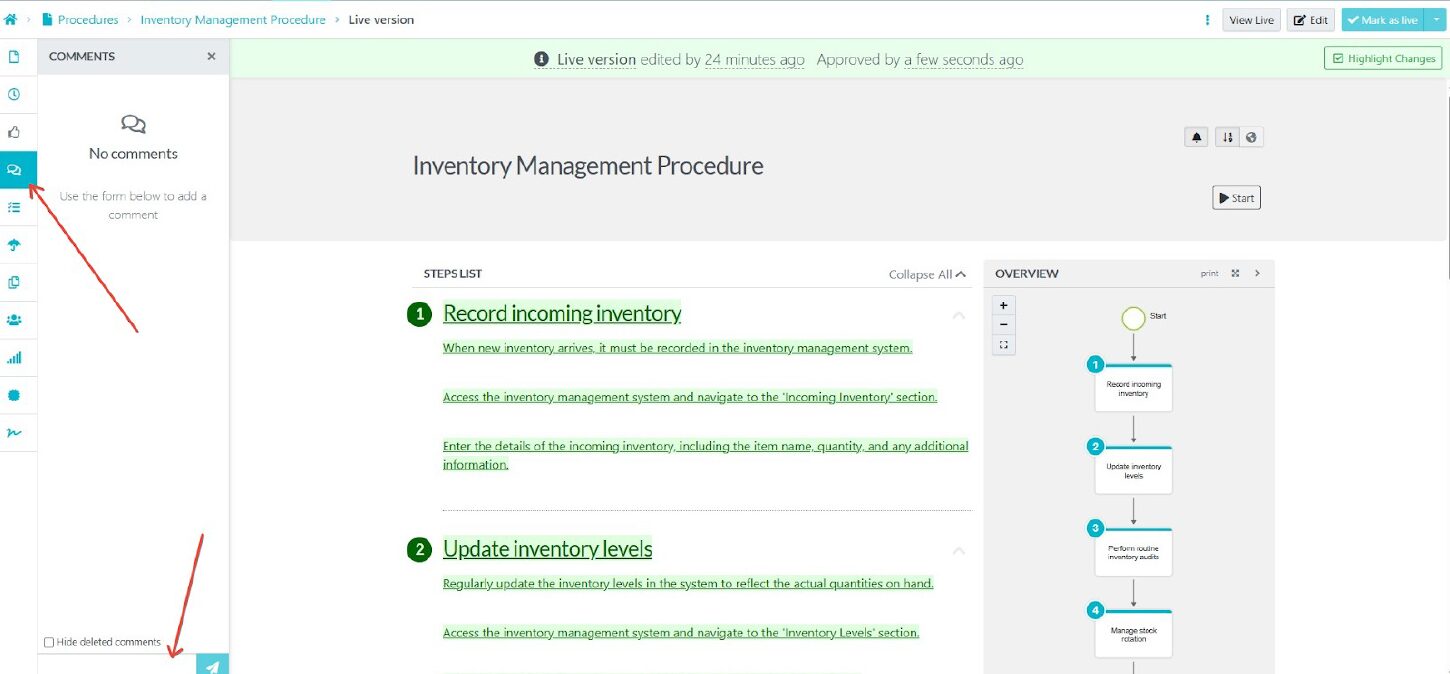

How to Create a Standard Operating Procedure (SOP) in SweetProcess

Documenting your standard operating procedures is straightforward in SweetProcess.

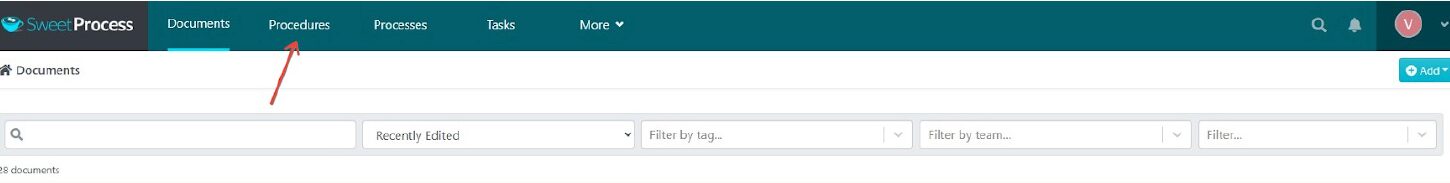

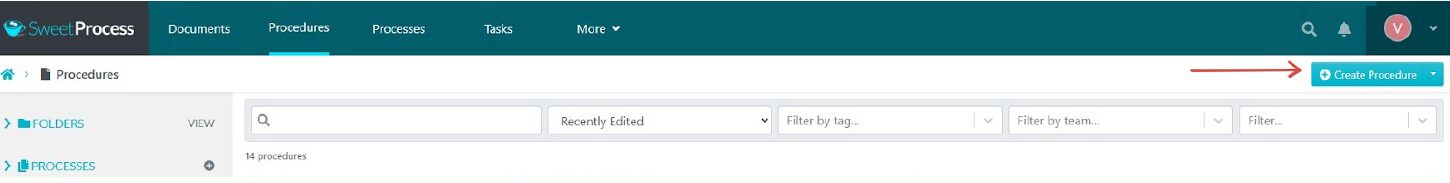

Start by clicking on the “Procedures” tab in SweetProcess.

You’ll find the “Create Procedure” button on the top right-hand side of the page. Click this to begin creating a new SOP.

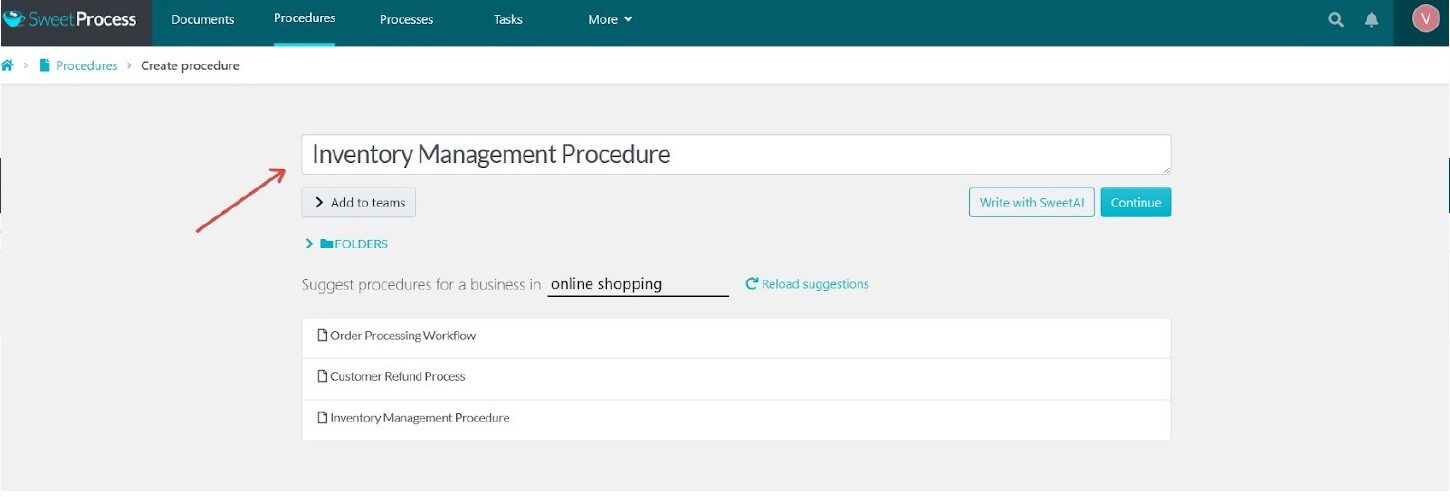

Give your procedure a descriptive title that indicates its purpose. For example, if you’re documenting a procedure for inventory management, title it “Inventory Management Procedure.”

You can assign the SOP to specific teams within your organization. Click on the checkboxes to allocate the procedure to one or multiple teams.

After assigning teams, click the “Continue” button to move to the next step in the creation process.

Click on the title of the procedure to add a detailed description. This should provide an overview of what the procedure entails and its purpose.

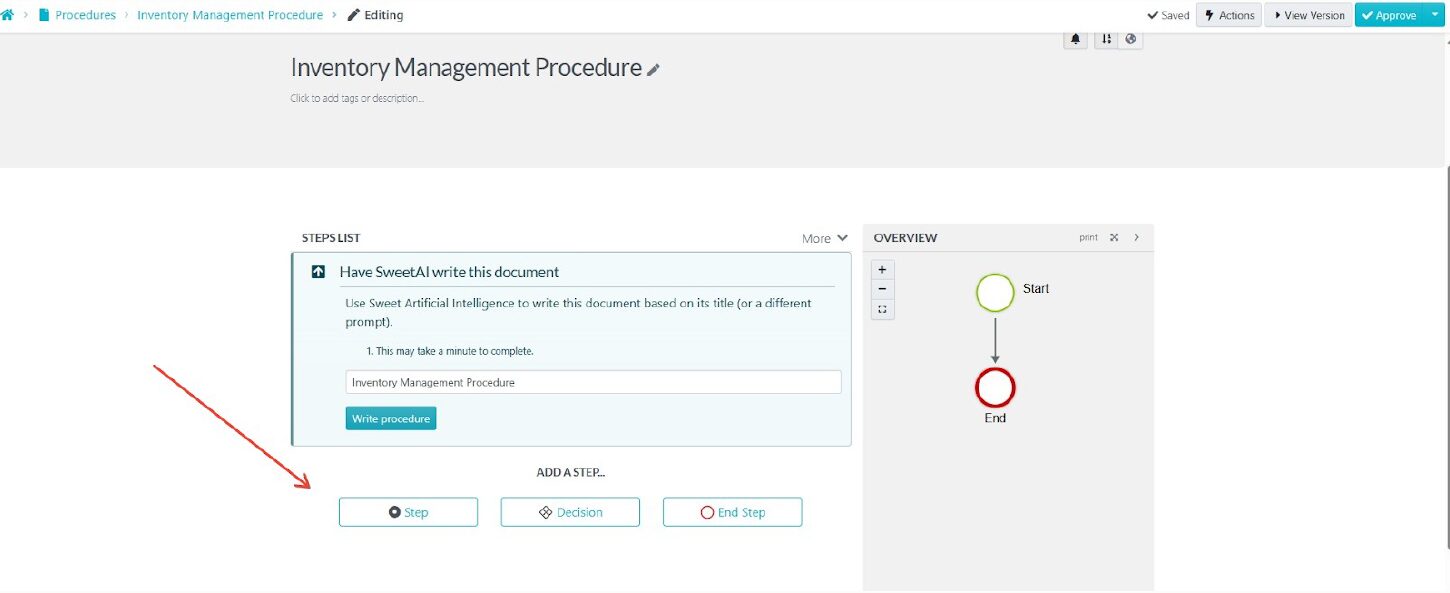

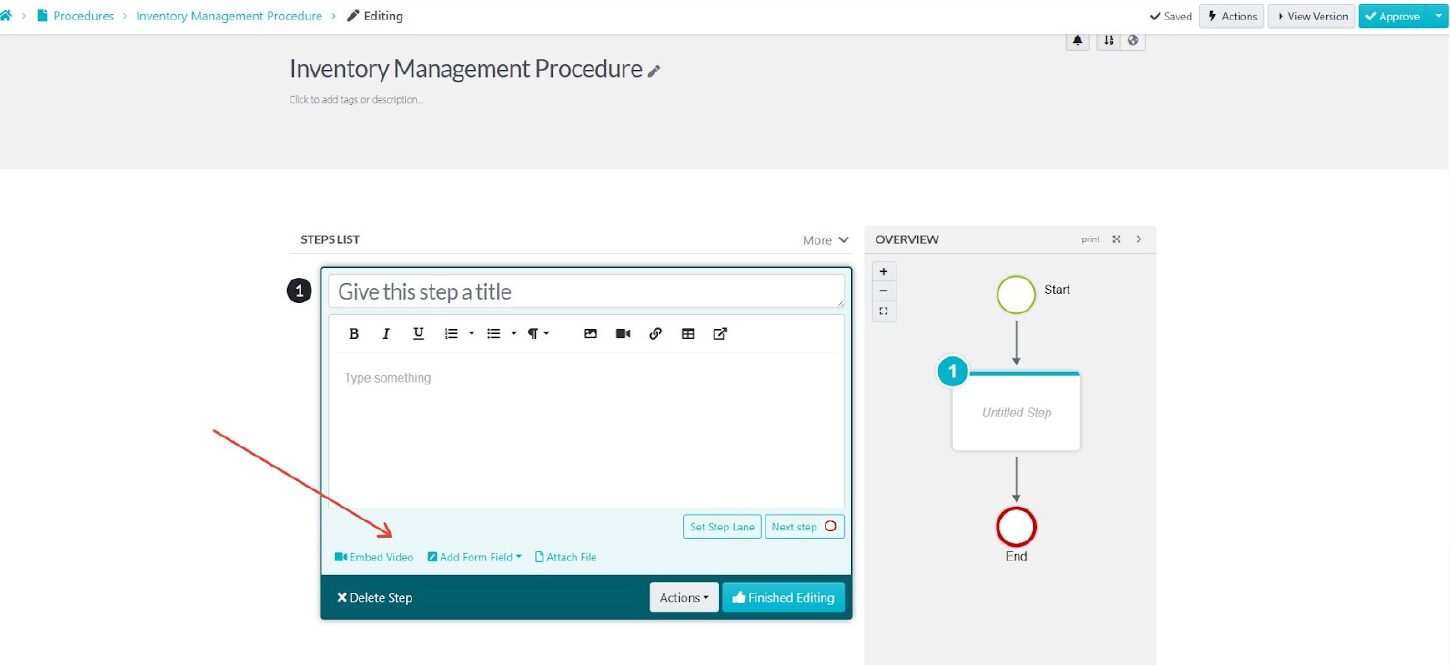

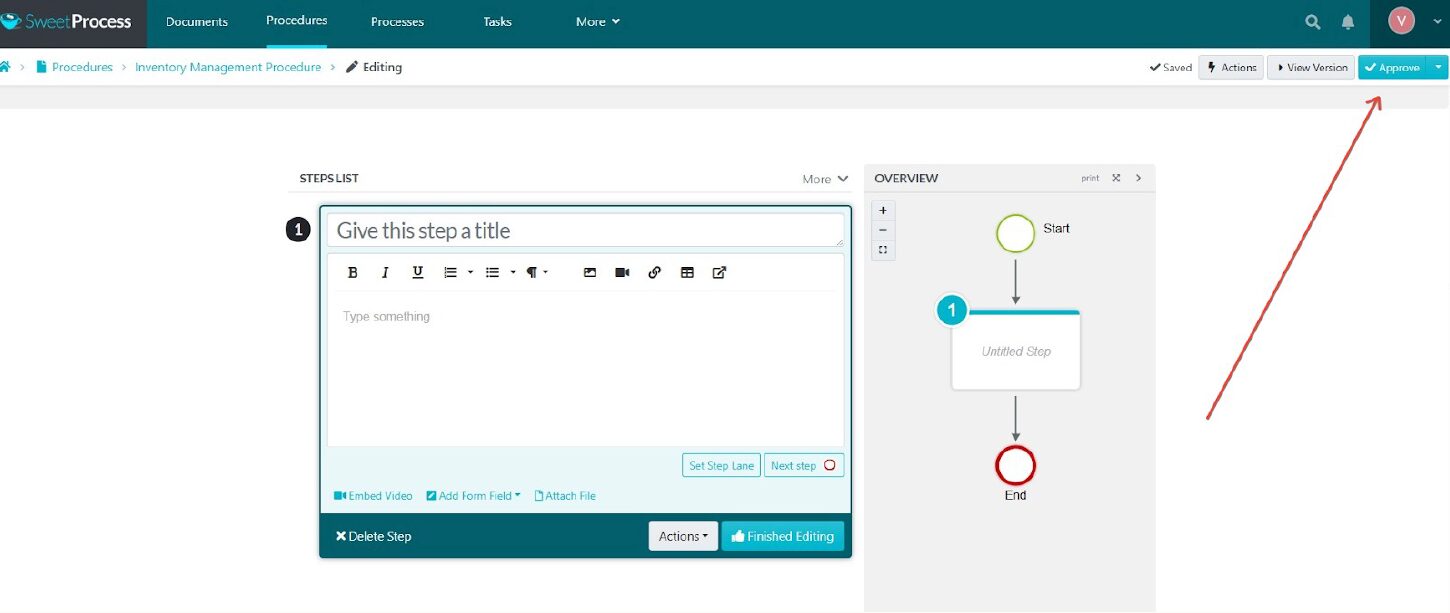

Next, start adding steps.

Click on the “Add a Step” button to begin detailing the steps involved in the procedure. Each step should outline a specific part of the process.

For each step, provide a clear title and a detailed description of what needs to be done. Be as specific and clear as possible to ensure easy understanding and implementation.

Attach files, images, or embed videos to each step if necessary. This can include diagrams, charts, or instructional videos that provide additional clarity.

After detailing a step and attaching any necessary materials, click on “Finished Editing” to save the draft of that step.

Once all steps are documented, click “Approve” at the top right-hand corner of the page. This action will make the procedure live and accessible to the assigned teams.

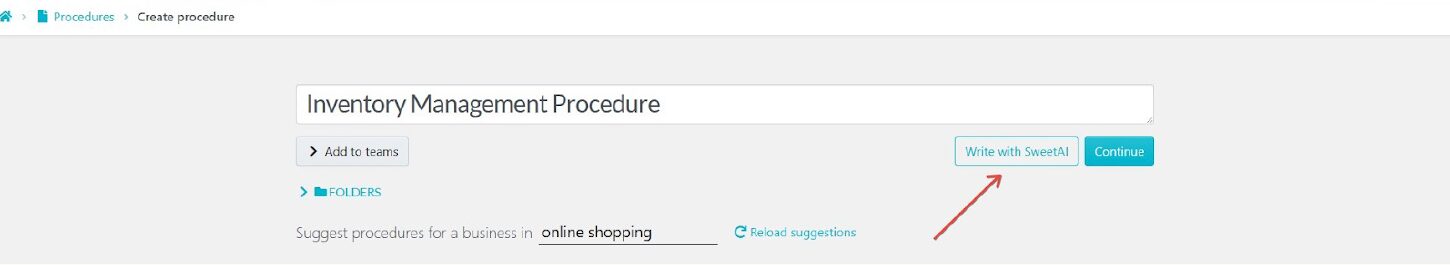

At SweetProcess, we have integrated artificial intelligence into documenting standard operating procedures (SOPs).

Start by naming your procedure. The title should be descriptive and reflect the nature of the task or process you document.

For instance, if you are creating a procedure for inventory management, title it “Inventory Management Procedure.”

After naming your procedure, take advantage of SweetAI by clicking the “Write with SweetAI” option. This feature leverages artificial intelligence to help you draft the procedure.

SweetAI will automatically generate a draft of the procedure based on the title you provided. This draft serves as an initial template and can cover key aspects of the procedure.

While SweetAI provides a starting point, review and customize the procedure to fit your organizational needs.

Edit the AI-generated content by adding specific details, instructions, or steps that are unique to your organization’s way of handling the process.

Incorporate any additional information, such as detailed instructions, best practices, safety guidelines, or quality standards relevant to the procedure.

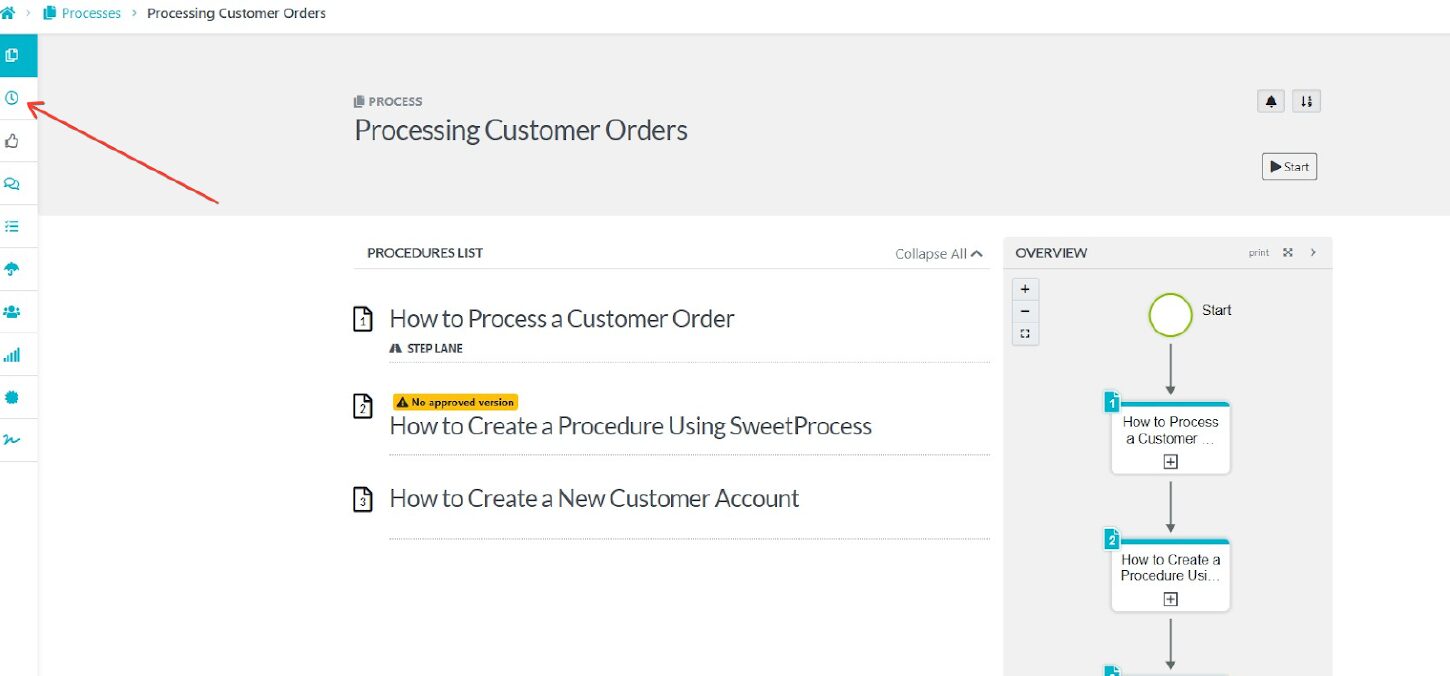

How to Track Historical Changes in SweetProcess

Tracking historical changes in SweetProcess allows you to view the evolution of a process over time.

This is useful in understanding how a process has been refined and adapted, which is crucial for continuous improvement processes (CIP).

Here’s how you can view the version history of a process in SweetProcess:

First, navigate to the specific process you want to review. Browse through your list of processes or use the search function to find the process quickly. Open the process by clicking on it.

While viewing the selected process, look for the clock icon. The icon is located in the toolbar. Click to see the version history of that process.

Once you click the clock icon, the version history sidebar menu will appear. This menu lists all the different versions of the process, including the current version and all previous versions.

In the version history sidebar, each version of the process is listed. You can click on any version to view the details of that specific process iteration.

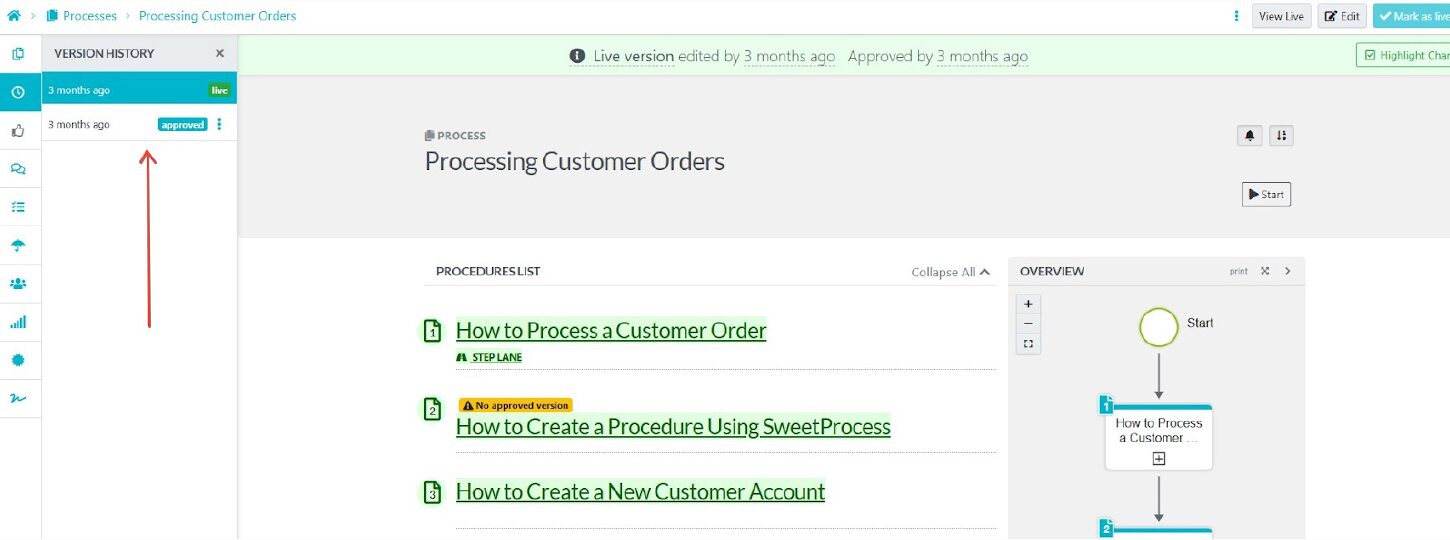

How to Leverage the Collaboration Features in SweetProcess

The ability to comment, collaborate, leave feedback, or suggest improvements to a procedure enhances communication and ensures that procedures are constantly refined and updated.

Start by navigating to the specific procedure on which you want to comment or provide feedback.

While viewing the procedure, look for the comment bubble icon. This icon is usually located in the toolbar. Click on this icon to open the commenting feature.

Once the comment section is open, you can type your comment, feedback, or suggestion for improvement directly into the provided text box.

Be as specific and detailed as possible to ensure your feedback is clear and actionable.

After typing your comment, click the paper plane icon to send it. This posts your comment on the procedure for other team members to see.

Every manager of the procedure, as well as anyone who has previously commented on the procedure, will be automatically notified of your new comment.

Employees who are notified of your comment can choose to respond directly within SweetProcess or by replying to the email notification.

The comment feature in SweetProcess is a tool for ongoing collaboration and discussion. Encourage your team to regularly review and comment on procedures, fostering a continuous dialogue around process improvement.

How XL.net Used SweetProcess to Improve Performance by Removing Clutter in Its Business Processes

At XL.net, CEO Adam Radulovic faced a big challenge. With over 2,000 processes cluttering the company’s operations, it became clear that more processes didn’t equate to higher efficiency.

This “massive garage worth of processes” led to confusion and underutilization as employees struggled to discern which processes were beneficial.

The time and resources spent on creating these processes could have been better spent.

SweetProcess offered a platform that simplified the documentation and management of these processes, allowing for a more organized and accessible approach.

This clarity and streamlining brought immediate benefits. It eliminated redundancies and outdated procedures, making it easier for staff to understand and follow the most relevant and efficient processes.

The impact of SweetProcess at XL.net went beyond the organization. It directly contributed to improved performance and customer satisfaction.

Benefits of Continuous Improvement Process in Your Business

The CIP approach grows a proactive culture of constant refinement, innovation, and adaptability. Your organization will always be at the forefront of industry standards and customer expectations.

How is this beneficial?

- Adaptability to change

CIP instills a mindset of flexibility within the organization.

By continually assessing and improving processes, employees become more accustomed to change and better prepared to adjust their approaches in response to external shifts.

It also fosters a learning environment where employees are encouraged to develop new skills and knowledge.

2. Quick problem resolution

In any business, issues and challenges are inevitable, but the efficiency with which you address them makes a significant difference in performance and customer satisfaction.

CIP encourages the monitoring of ongoing improvement and analysis of processes. This often leads to the early detection of potential problems before they escalate.

Also, methods like root cause analysis help address a problem’s symptoms and understand and resolve the underlying cause.

3. Fosters innovation

CIP creates a culture where you encourage your employees to think creatively and question the status quo.

This mindset is essential for innovation. It motivates individuals to explore new ideas and solutions.

A core principle of CIP is the understanding that not all changes will be successful on the first try. This acceptance creates a safe environment for experimentation. Your employees will feel comfortable proposing and testing new ideas without fearing failure.

4. Positive organizational culture

CIP actively involves your employees in the process of identifying and implementing improvements.

This gives employees a sense of ownership and responsibility for their work, increasing job satisfaction and a more committed workforce. In turn, it will result in customer satisfaction, positively impacting the bottom line.

Studies show that customer and staff satisfaction will rise by 54% due to continual improvement.

5. Enhanced product quality

CIP involves consistent monitoring and evaluation of product quality.

Incorporating lean process improvement ensures that feedback from both internal teams and customers is effectively used to refine products and eliminate inefficiencies.

By addressing root causes rather than just symptoms, businesses can implement lasting improvements that elevate product standards and enhance customer satisfaction.

6. Risk and waste reduction

CIP focuses on streamlining processes, eliminating inefficiencies, enhancing performance, and contributing to cost savings and sustainability.

A real-world example of this in action can be seen in Toyota’s implementation of the lean manufacturing approach.

Toyota applies principles of lean manufacturing, a key component of CIP, to minimize waste.

This involves identifying and eliminating “Muda” (waste) in manufacturing, which includes unnecessary steps, overproduction, and excess inventory.

7. Long-term sustainability

Continuous improvement will help your business adapt and respond to market changes and customer needs.

How? As we saw earlier, CIP fosters a culture of innovation.

By continuously seeking better ways to operate and serve customers, you can stay ahead of the curve, offering innovative solutions that meet changing consumer demands.

Tools for Successful Implementation of Continuous Process Improvement

When you’re working on making your business better all the time, having the right continuous improvement tools can make a big difference.

These tools help you determine what needs to change, make those changes, and finally check to see if the changes worked.

1. Pareto analysis

Pareto analysis is based on the idea that in many situations, 80% of the effects come from 20% of the causes.

Pareto analysis helps identify the most significant issues within a process or system.

By focusing on the “vital few” rather than the “trivial many,” you can target your efforts on areas with the greatest impact on performance and efficiency.

For example, in the graph above, the blue bars indicate the percentage of each issue contributing to overall problems or inefficiencies within the business.

- For instance, “Late Deliveries” might be responsible for 40% of the total issues.

- The green line and markers show the cumulative percentage.

- This demonstrates the principle behind Pareto analysis—focusing on the few critical issues (in this case, “Late Deliveries” and “Defects in Product”) could address a significant portion of the problems, adhering to the 80/20 rule.

Addressing these key issues first can substantially improve overall operational efficiency and customer satisfaction.

2. 5 Whys

The “5 Whys” technique involves asking the question “Why?” five times (or as many times as needed) to peel away the layers of symptoms and reach the core of a problem.

Start with a clear statement of the problem. This problem should be specific and observable.

- Ask the First “Why”: Ask why the problem is occurring. This first answer will often lead to another question.

- Continue with Subsequent “Whys”: After each response, ask another “Why?” based on the previous answer. This process is repeated until the root cause of the problem is identified. This takes about five iterations, but it can vary.

The goal is to drill down to the root cause of the problem, which is often a process or system-related issue rather than a people-related issue.

3. Fishbone/cause-and-effect diagram

The fishbone diagram, also known as the cause and effect, or Ishikawa diagram, is a root cause analysis template used to identify and visualize the root causes of a specific problem.

It helps systematically break down the factors contributing to the problem.

Take an example of a retail store experiencing a sudden drop in sales. To understand the root causes of this decline, the management team decided to use a fishbone diagram.

- Problem Statement: At the head of the fishbone, the problem is clearly stated: “Decreased Sales in the Last Quarter.”

- Identifying Categories: The main bones of the fish are categorized into potential areas that could impact sales:

- Methods (sales strategies, customer service practices)

- Machines (point of sale systems, other technical equipment)

- Materials (product quality, inventory levels)

- Manpower (staff skills, staffing levels)

- Measurement (systems for tracking sales and customer feedback)

- Environment (store layout, location, market trends)

- Brainstorming Under Each Category:

- Methods: Perhaps there’s been a change in sales strategy that’s not resonating with customers, or customer service has declined.

- Machines: The point of sale system might be outdated, causing slow service.

- Materials: Maybe there’s an issue with the quality or variety of products offered.

- Manpower: Staff might lack proper training, or there may be insufficient staffing during peak hours.

- Measurement: It’s possible that the store isn’t effectively tracking key sales metrics or customer feedback.

- Environment: Changes in the local market or an unappealing store layout could be factors.

After brainstorming, the team might find that key issues include an outdated sales strategy (methods), inadequate staff training (manpower), and poor store layout (environment).

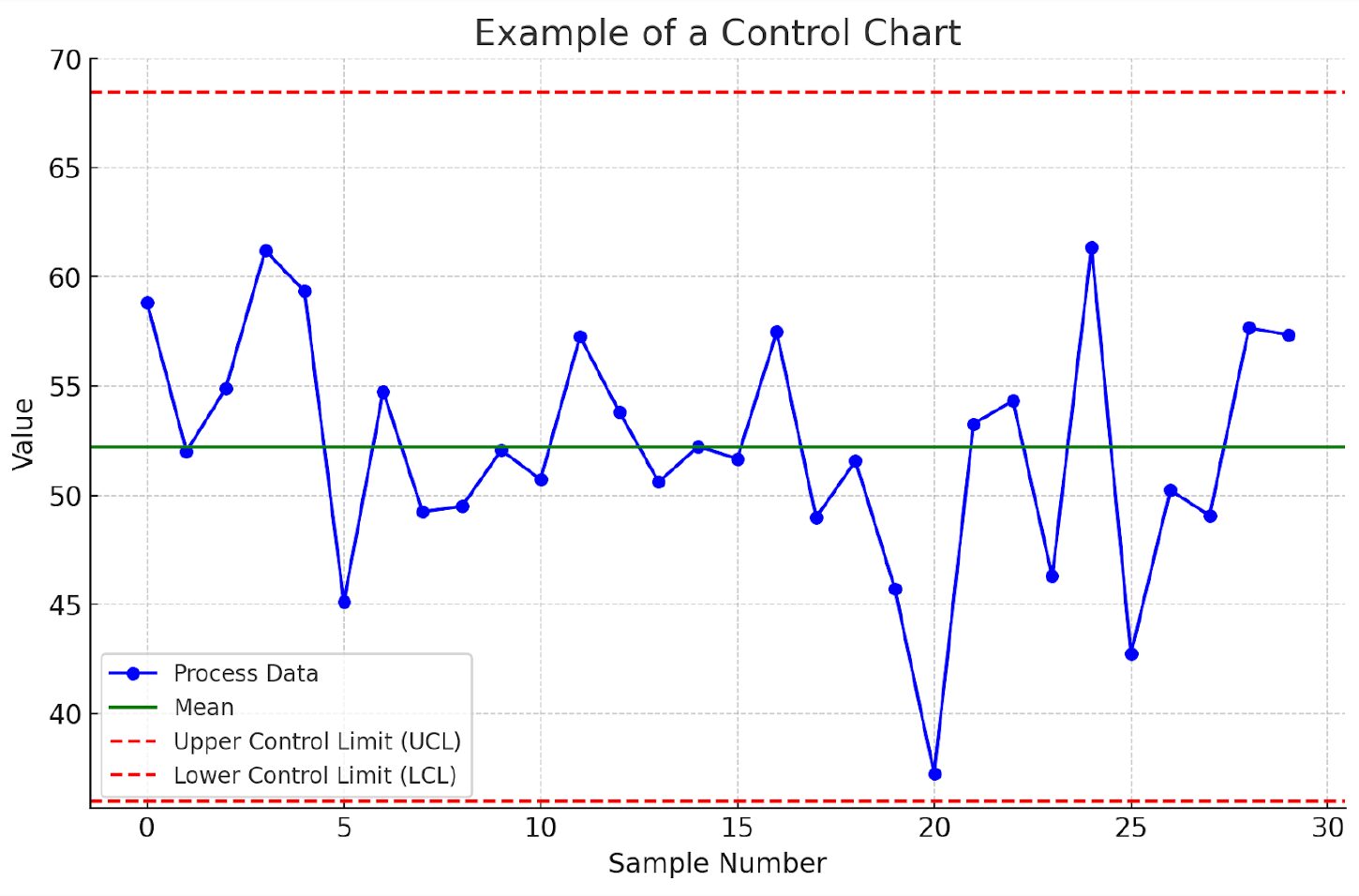

4. Control charts

Control charts graphically display process data over time. They show the process mean (average), control limits, and acceptable variation boundaries.

The purpose of a control chart is to distinguish between common cause variation (natural variation inherent in the process) and special cause variation (due to specific, identifiable factors).

By regularly plotting data on a control chart, you can monitor the stability and control of your processes.

Points falling outside the control limits or showing non-random patterns (like a series of points steadily increasing or decreasing) indicate that the process may be out of control and needs investigation.

In this control chart:

- The blue dots represent individual data points of a process over time. In this case, it’s a series of 30 samples.

- The green line indicates the mean (average) of the process data, serving as a central reference point.

- The two red dashed lines represent the upper control limit (UCL) and lower control limit (LCL). These are set at three standard deviations above and below the mean.

If the data points consistently fall within the control limits, the process is considered stable and in control. However, suppose data points fall outside these limits or show a non-random pattern (like several points in a row steadily increasing or decreasing). In that case, it suggests that the process may be out of control due to special cause variation.

5. Benchmarking

Benchmarking involves comparing your business process improvement and performance metrics to industry bests or best practices from other companies.

The first step is to identify the aspects of your business that you want to benchmark.

Choose companies or industries against which to benchmark your processes. These can be direct competitors, industry leaders, or businesses renowned for operational excellence in specific areas.

Collect data on how your selected benchmarking partners handle the processes or performance metrics you’re focusing on.

Next, analyze your processes in comparison with the benchmark. Based on your findings, develop strategies to close gaps, improve processes, and adopt best practices.

6. Flowchart

A flowchart visually represents the steps in a process, showing how they connect and flow from one to the next.

Flowcharts help identify redundancies, bottlenecks, and inefficiencies by mapping out the steps.

Seeing the entire process laid out visually makes it easier to pinpoint where delays or unnecessary steps occur.

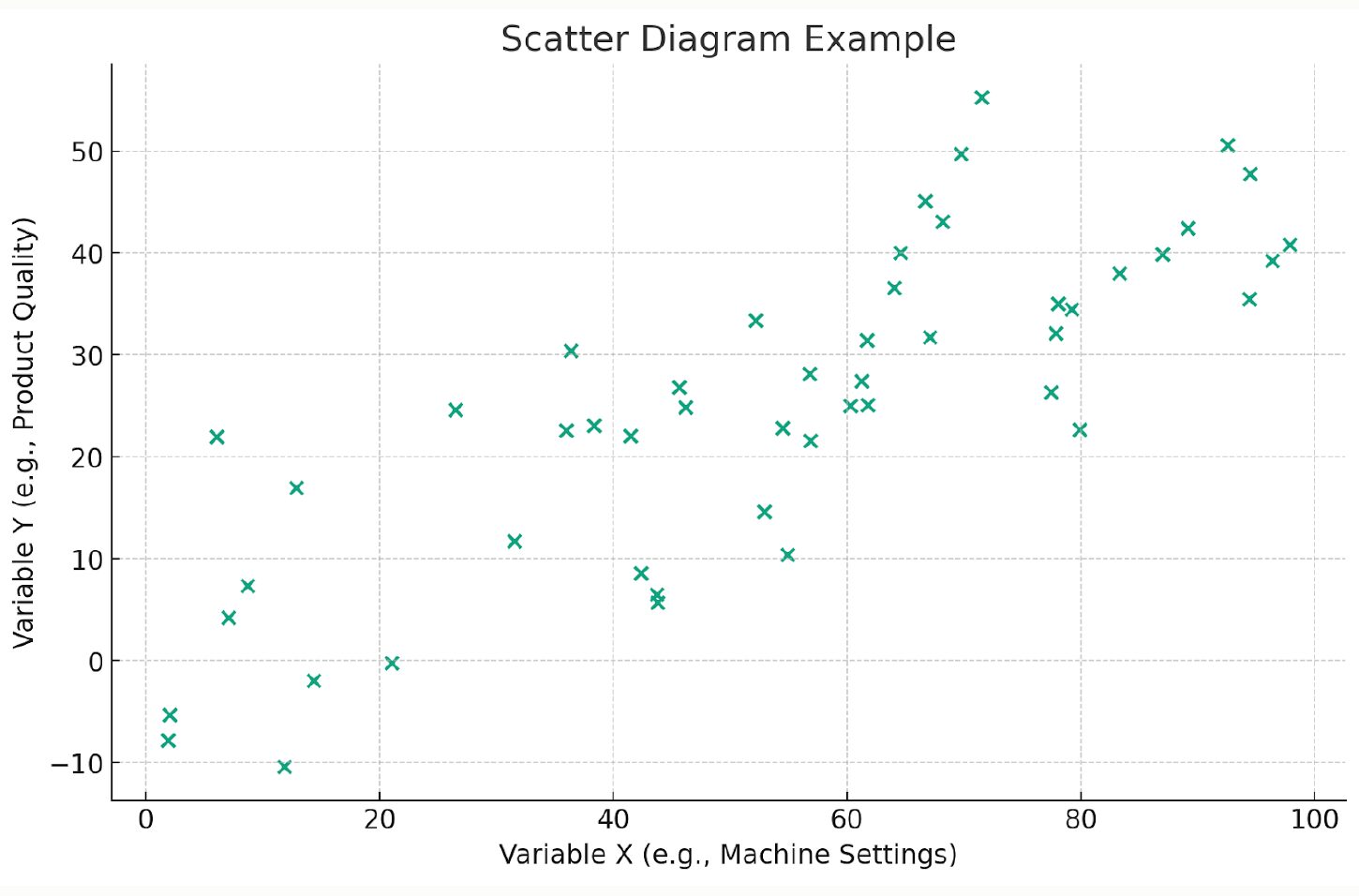

7. Scatter diagram

A scatter diagram, or a scatter plot, analyzes and visualizes the relationship between two variables.

In a scatter diagram, individual data points are plotted on a graph, with one variable represented on the X axis and the other on the Y axis. Each point represents a pair of values for these two variables.

By observing the pattern of the data points, you can identify if there’s a relationship between the two variables. For example, a positive correlation, negative correlation, or no correlation at all.

In the scatter diagram:

- Each dot represents a single observation, combining a value from Variable X and Y.

- The horizontal axis (X axis) shows values for “Machine Settings,” while the vertical axis (Y axis) displays values for “Product Quality.”

By observing the spread and pattern of these dots, you can see if there’s any relationship between the two variables. For example, if you notice that higher values of Machine Settings (X) tend to correspond with higher Product Quality (Y), this could suggest a positive correlation.

This diagram is useful in continuous improvement processes for identifying potential relationships and correlations that warrant further investigation.

For instance, if this scatter diagram suggests a strong relationship between machine settings and product quality, it could lead to more focused and effective improvements in the manufacturing process.

8. SWOT

SWOT analysis is a planning tool to evaluate the strengths, weaknesses, opportunities, and threats involved in a project or business venture.

Identifying the strengths of your organization gives insight into what is working well.

Also, acknowledging weaknesses allows you to pinpoint areas that need improvement.

Regular SWOT analyses will help keep your business aligned with its goals and external environment.

9. Gemba walks

Gemba walks originates from the Japanese term “Gemba,” which means “the real place.”

Gemba walks involve managers and leaders going to the front lines of their business—where the work process is actually done—to observe, learn, and engage with employees.

Leaders gain a clear and accurate understanding of processes by observing how work is performed rather than how it is presumed to be performed.

This allows leaders to address issues and challenges at their source. This on-the-spot problem-solving is more effective than resolving issues from a distance.

Types of Continuous Improvement Methodologies

The core idea of CPI remains the same—to make operations more efficient and effective—but there are various methodologies that you can adopt to guide your continuous improvement efforts.

1. PDCA

PDCA is a four-step continuous improvement model that provides a simple structured approach to solving problems and managing change.

- Plan: Identify a problem or opportunity for improvement, gather relevant data, and plan the necessary change.

- Do: In the do phase, implement the plan on a small scale. This could involve a pilot test or a trial run to introduce a small change or improvement.

- Check: Once the plan has been implemented, the check phase evaluates the results. It involves collecting and analyzing data to see if the objectives set in the plan phase were met.

- Act: Based on the findings from the check phase, the act phase is where you make adjustments. If the plan is successful, the changes can be standardized and implemented on a larger scale. If the plan didn’t achieve the desired results, use the insights gained to inform a new PDCA cycle.

2. Lean

Originally developed by and used in the Toyota production system for its manufacturing operations, lean principles have been widely adopted across various industries.

The idea of lean is to create more value with fewer resources by optimizing the flow of standard work.

Lean starts with defining value from the customer’s perspective. The goal is to understand what customers really value and are willing to pay for, ensuring that the business focuses on creating that value.

3. Six Sigma

Six Sigma aims to achieve a level of process performance that results in no more than 3.4 defects per million opportunities.

Six Sigma is associated with the DMAIC framework, which stands for define, measure, analyze, improve, and control.

Take an example of a manufacturing company that produces electronic components. The company has been facing challenges with a high rate of defects in one of its popular products, leading to customer complaints and returns.

To address this issue, the company decided to implement Six Sigma using the DMAIC framework:

- Define: The project begins with defining the problem: a high defect rate in electronic component production. The goal is to reduce the defect rate by 50% within six months.

- Measure: The team collects data on the current production process and quantifies the defect rate. They establish a baseline to measure improvements.

- Analyze: Using Six Sigma analytical tools, the team analyzes the data to identify potential causes of defects. They discovered that most defects are due to two main issues: variance in raw material quality and calibration errors in the manufacturing equipment.

- Improve: The team develops and implements solutions based on the analysis. They establish a stricter quality control process for raw materials and introduce regular calibration checks for the equipment.

- Control: The team sets up a new monitoring system to continuously track defect rates to sustain these improvements.

- Results: After six months, the company reviews the project and finds that the defect rate has been reduced by over 60%, exceeding the initial goal.

4. Kaizen

Kaizen is one of the most recognized process improvement methodologies, and it regularly makes small, incremental changes to improve efficiency and quality. In Kaizen, everyone in the organization, from top management to front-line employees, emphasizes a culture of sustained continuous improvement. Unlike some continuous improvement methods that aim for large-scale transformations, Kaizen focuses on small, manageable changes that you can implement quickly.

5. TQM

In a total quality management effort or TQM, every member of your organization is involved in improving processes, products, services, and work culture.

A hotel chain has been experiencing a decline in customer satisfaction scores and increased complaints regarding service quality. To address these challenges, the hotel chain decided to implement TQM principles.

- The hotel begins by conducting comprehensive surveys to understand customer expectations and experiences.

- Every employee, from the front desk staff to the housekeeping team and management, is involved in the improvement process.

- The management reviews all operational processes, including check-in and check-out procedures, room cleaning, food and beverage services, and maintenance.

- The TQM initiative is integrated across all departments. For instance, the kitchen staff improves food quality and presentation, while the maintenance team focuses on timely repairs and upkeep of facilities.

6. 5S

5S methodology is derived from five Japanese words:

- Seiri

- Seiton

- Seiso

- Seiketsu

- Shitsuke

This approach focuses on efficiently organizing and managing the workspace to improve productivity and safety.

| Seiri (Sort) | Sorting through all items in a workspace and keeping only what is necessary. |

| Seiton (Set in Order) | Once you identify the necessary items, organize and arrange them in a way that promotes efficiency. |

| Seiso (Shine) | This stage focuses on cleaning the workspace, ensuring it’s neat. |

| Seiketsu (Standardize) | Standardization of the first three steps to ensure consistency—creating schedules, checklists, and guidelines to maintain the order. |

| Shitsuke (Sustain) | Maintaining and reviewing the standards. Creating a culture where all employees follow the established procedures and contribute to keeping the workspace organized and efficient. |

By reducing clutter and streamlining the organization of tools and materials, 5S helps reduce time wasted searching for items.

Tips for Nurturing a Culture of Continuous Improvement in Your Company

Creating a culture of continuous improvement within your company leads to numerous benefits, including increased efficiency, higher employee engagement, and sustained competitive advantage.

In this section, we’ll explore practical tips on how to grow this culture where continuous improvement is fundamental to your company’s ethos.

1. Integrate open-door policy

Leaders and managers should be approachable and available for discussions with employees.

Also, make it known that feedback and ideas are welcomed and valued.

Employees should feel comfortable sharing their insights and suggestions without fear of criticism or negative repercussions.

2. Recognize and celebrate success

Recognition of efforts and successes, big or small, motivates employees and reinforces the value of striving for betterment.

Employees who receive regular recognition are five times more likely to feel valued and appreciated and six times more likely to invest in their work.

Recognition doesn’t always have to be monetary. Public acknowledgment, certificates of achievement, thank-you notes, or even an extra day off are powerful motivators.

3. Learning from failures

Learning from failures is a key aspect of continuous quality improvement. Create an environment where employees feel safe to take calculated risks and experiment, knowing that setbacks are opportunities for growth.

Assure them that failures are a natural part of the learning process and should not be penalized. Instead of assigning blame, focus on what can be learned from each experience. Ask questions like:

- What can we do better next time?

- How can this teach us to improve our processes or decision-making?

By fostering a culture of learning and adaptation, your organization can drive continuous quality improvement and long-term success.

Build a Culture of Continuous Improvement in Your Organization

Consistency is key. Regularly applying continuous improvement methodologies and principles ensures these practices become ingrained in your organizational culture.

It’s not just about introducing new ideas but also about consistently refining and improving them over time.

A tool like SweetProcess plays a transformative role.

SweetProcess streamlines the implementation of the continuous improvement initiative by making it easy to document, manage, and optimize Standard Operating Procedures (SOPs).

By choosing SweetProcess, you empower your team with the resources they need to drive continuous improvement in an organized and efficient manner.

Sign up for a free trial today and experience firsthand how it can transform your organization’s continuous improvement approach.