Last Updated on May 6, 2025 by Owen McGab Enaohwo

When a business takes that jump from small to more substantial, it can lose footing. Customers might complain that the product they used to love has lost the high quality they appreciated about it. The question becomes, how do you maintain quality while producing more?

Every business wants to present quality offers, but not everyone understands what it takes and how to have the best quality. And managers often get this wrong.

In this article, we will look at the quality improvement process, uncover the must-haves in a good QIP, and study the methods, tools, and steps to build a sound strategy.

SweetProcess is our software, and it’s built for teams to create and manage quality improvement documents and procedures in one place so they can focus on what drives real business growth. Without adding your credit card info, you can sign up for our 14-day free trial to see how it works.

TABLE OF CONTENTS

What Exactly Is a Quality Improvement Process?

Importance of Quality Improvement Process in a Business

Key Steps for Planning an Effective Quality Improvement Process

Enhance Your Company’s Quality Improvement Process Using SweetProcess

Top Quality Improvement Methodologies

Common Quality Improvement Tools

Common Challenges of Quality Improvement Process

Key Ways to Measure the Quality Improvement Process

Quality Improvement Process in Healthcare

Build an Effective Quality Improvement Process With SweetProcess

What Exactly Is a Quality Improvement Process?

Quality improvement process (QIP) is a journey to enhance and refine the overall quality of an organization’s products, services, and processes.

The main essence is to identify areas that need improvement, implement changes, and always monitor outcomes to ensure constant improvement. It’s driven by a commitment to meet or exceed customer expectations, comply with industry standards, and achieve organizational goals.

Importance of Quality Improvement Process in a Business

Let’s look in more detail at the importance and benefits of the quality improvement process.

Enhanced Brand Reputation

When a business regularly offers great products and services, it builds trust with customers, who become loyal and recommend the business to others. QIP helps to make sure that quality is maintained consistently.

Employee Engagement and Satisfaction

QIP ensures clear communication, setting expectations and reducing frustration. This clarity builds trust, enhances teamwork, and promotes collaboration. Investing in QIP not only improves products or services but also creates a workplace where employees feel valued and satisfied.

A motivated and happy team is key to delivering the quality customers expect. QIP is not just a process tool; it’s also a strategy for engaging employees, leading to overall business success.

Adaptability to Change

Change is constant, especially in a competitive market. The ability to adapt quickly can make or mar a brand. That’s where a strong QIP helps you build. It encourages you to stay vigilant, anticipating changes like shifts in customer behavior or new competitors. It promotes a culture of innovation by seeking better ways to operate.

Cost Reduction

Mistakes can be expensive, leading to rework, refunds, lost sales, and damage to your brand. QIP focuses on error prevention before they become complex issues and saves the costs of fixing mistakes. But it doesn’t stop there. QIP leads to long-term savings by promoting continuous learning and development. As you improve, you better understand processes, team capabilities, and customer needs, making informed decisions about technology, hiring, and market expansion.

Regulatory Compliance

QIP helps your business adhere to industry standards, regulations, and laws. It is a built-in guide, ensuring your business is on the right track. QIP prioritizes documenting every process and change, creating a reliable trail of evidence for compliance.

While it may seem like a lot of paperwork, this documentation serves as proof during audits or inspections, demonstrating that your business follows the rules.

Improved Productivity

Quality improvement process can transform your business into a productive powerhouse where you work smarter, not harder, and achieve more with less.

Key Steps for Planning an Effective Quality Improvement Process

Let’s go over these ten important steps to plan a quality improvement process for your company.

Define Your Goals

Before you plan to improve your work, you must decide what you want to achieve. What are you trying to do with this improvement process? Do you want to spend less money, make customers happier, or get more work done?

Once you know your goals, you can start working toward them. Ensure your goals are specific, achievable, trackable, significant, and have a deadline.

Identify and Analyze the Current Situation

This step involves collecting information and evaluating your current workflows to identify areas for improvement. By using tools such as process maps, charts, and checklists, businesses can document existing methods and pinpoint inefficiencies.

Implementing lean process improvement at this stage helps streamline operations by eliminating waste and optimizing performance. Once you have a clear understanding of your processes, brainstorming solutions with your team ensures a well-rounded approach, incorporating valuable insights that may have been overlooked.

Engage Stakeholders

Now that you’ve figured out where things can get better and chosen the right methods and tools, it’s time to involve the people that the changes will affect—your stakeholders.

Start by telling them about the goals and good things that will come from improving things. Explain how it will affect their work and answer questions they might have. Ask for their ideas and thoughts on how to make things better. This not only helps make sure the changes work well but also gets them more involved and feel responsible for the process.

Identify Improvement Opportunities

In order to improve your processes, you need to identify opportunities for improvement. It’s achievable by analyzing your current business processes and looking for areas of waste, inefficiency, or error. You may also want to gather feedback from your stakeholders to identify problems or areas where they see room for improvement.

Keep in mind that quality improvement ideas can come from sources you least expect, so be open to suggestions from your team and stakeholders.

Set Measurable Goals

After figuring out what you want to achieve and where you can make things better, the next step is to make sure your goals are measurable. This means making sure your goals are specific, measurable, achievable, relevant, and time-bound (SMART).

For instance, if you want to reduce customer complaints, you could set a goal to decrease complaints by 20% in the next six months. This way, you have a specific target to aim at and a deadline to reach it.

Select Improvement Methodology and Tools

Choose from the various tools available, which could be lean, Six Sigma, or agile. Each method has its tools and techniques to find and fix problems, reduce mistakes, and boost employee productivity. However, when deciding on the method and tools, think about the business you have, how big your company is, and the QI project size.

Implement Strategy

This is where all your QI efforts in the previous steps come together. You’ll need to create a quality improvement project plan outlining the specific tasks and timelines for each part of the process.

Involve your team and stakeholders in the implementation, and ensure everyone has clear roles and responsibilities. Stay organized and take records during the implementation so you can spot any obstacles early on and make adjustments.

Monitor and Evaluate Progress

After you’ve put your quality improvement plan into action, it’s important to monitor your progress and ensure you’re on the right path to reaching your goals.

Schedule regular checks with your team and stakeholders to review the progress and pinpoint any issues or areas where you can improve. Be open-minded and be ready to change your approach when necessary.

Collect Feedback

While you’re making improvements to your QI process, it’s essential to hear from your team members. Their feedback can point out areas you can improve or your process might not work for them. You can collect feedback through surveys, interviews, or observations. You can also use data to track progress and spot places for improvement.

Standardize and Build a Culture of Continuous Improvement

You can do this through regular training, continuous iteration, and having a Standard Operating Procedure (SOP). However, getting feedback and monitoring the entire process without a platform that automates everything is stressful and time-consuming. You can also use SOP software, so you can automate the process and focus on growing your business.

Enhance Your Company’s Quality Improvement Process Using SweetProcess

Yes, you can use SweetProcess to enhance your quality improvement program. Let’s look at how our software can help you.

Document Your Process to Identify Opportunities for Improvement

SweetProcess can help you prevent scattered documents or misinformation in your quality improvement journey.

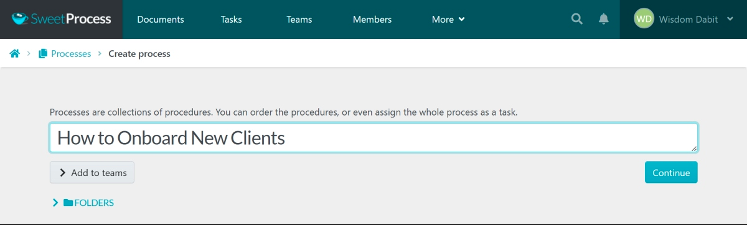

To do this, log in to SweetProcess, head to the drop-down ‘’More’’ button, and click on the “Processes” tab. After this, click on the “Create Process” button, enter a title for your process, then click “Continue.”

Then use the AI-suggested description or manually write a description of the steps to be followed to complete the process. This will help you easily spot bottlenecks later and make adjustments.

When choosing your description, always ensure that it’s simple, concise, and straight to the point. Once you’re okay with the output, click on the “Approve” button to save it.

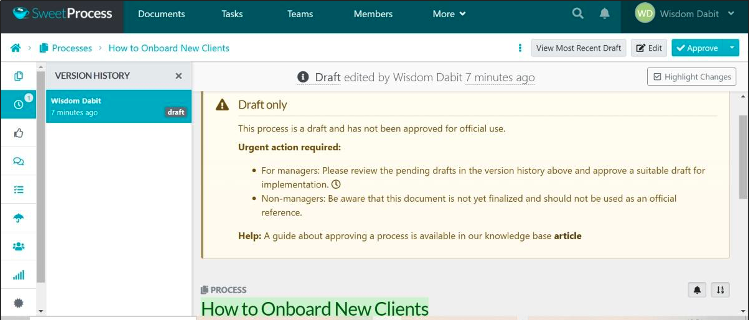

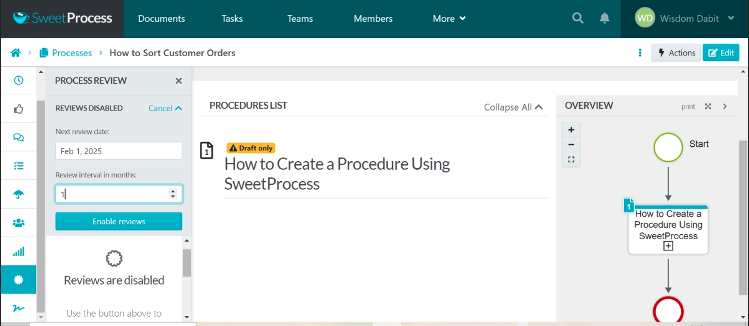

As you can see in the image below, SweetProcess gives you the chance to know who edited or adjusted what and when exactly. Plus, you can trace each previous process version, so you can easily identify where to make adjustments.

Once you’re okay with the output, click on the “Approve” button to save it.

Leverage Reports and Analytics in SweetProcess to Make Data-Driven Decisions

SweetProcess also allows you to keep track of process data: every action, step, and task completion time is tracked, giving you a wealth of insights.

And you can use it to track changes and generate and analyze reports to see how improvements affect the quality of different procedures and processes.

As you can see in the image below, almost every important data you need is clearly shown: version history, the personnel who edited or approved a procedure, description of a process or procedure, toggles for approving requests, sign-off log, enable, disable, or preset review dates and number of times this can be done, check approval requests, and related tasks.

SweetProcess makes quality improvement a straightforward process, as it offers an easy-to-use platform that houses process steps. For instance, at Thimbleberry Financial, Amy Walls, president, and financial advisor, explained how documentation on SweetProcess helps them achieve this.

Their old process documentation on Microsoft Word worked until they started having high turnovers. The team couldn’t follow the process steps, and it led to chaos in their daily operations.

SweetProcess helped Amy and her team create documentation that allowed them to easily spot errors, inadequacies, and what were causing operational missteps; plus it helped enhance their overall service delivery.

“Once we started plugging things into SweetProcess, I found the team was finding, ‘Oh, these other documentations are missing so many steps,’ and we found part of the things that makes our processes and procedures more difficult…because we do the comprehensive plan and wealth management, there’s lots of crossover between things,” Amy explained.

Likewise, Tom, the quality assurance and sensory coordinator at Stone & Wood, was tasked with maintaining quality assurance and smooth operations.

Now, aside from being consistent with the taste and quality of its beer, it has to abide by the regulatory standards in its industry or risk being sanctioned. However, stepping up to the plate is a struggle because of the absence of an effective quality control system.

The binders and Microsoft Word documents the organization was working with were insufficient. Employees working with outdated procedures could alter the entire production, leaving the team with no option but to start afresh—a big waste of time and resources.

Tom took up the responsibility to resolve the problem. After trying several systems, he found the solution in SweetProcess.

In his words: “It gets a lot of use for onboarding new staff. We often get casual labor for a single day’s work. To do that, they have to go through safety induction, quality induction, and various other little documents, so we’ve actually put them all into SweetProcess. We can assign that process as a task to someone, and they can read through it at their own pace, tick it off, and then the manager can come back and see that they have done all of that. It’s working well for us in that regard.

“It really helps us a lot with standard requirements that are out there like the International Organization for Standardization (ISO) where you have to demonstrate that your employees have been trained and show procedure documents, so it ticks all the boxes there,” he added.

SweetProcess is built to help teams create and manage quality improvement documents and procedures in one place so they can focus on what drives real business growth. Without adding your credit card info, you can sign up for our 14-day free trial to see how it works.

Top Quality Improvement Methodologies

Now let’s look at some of the top quality improvement methodologies.

PDCA cycle

The PDCA, or Deming Cycle, stands for plan, do, check, and act. First, plan by setting goals. Do this by implementing changes and gathering data. In the check phase, observe the results and adjust accordingly. Finally, act by adopting and adjusting based on your analysis.

The PDCA cycle is a continuous loop for ongoing improvement that provides a structured framework to address challenges and enhance quality.

Six Sigma

Six Sigma is a great way to make things better. It started in the 1980s at companies like Motorola and General Electric. The goal is to have an almost perfect process with very few mistakes. There are two major ways to use Six Sigma: DMAIC and DMADV.

- DMAIC (define, measure, analyze, improve, and control) is for fixing existing problems.

- DMADV (define, measure, analyze, design, and verify) is for making new things.

Kaizen

Kaizen is a Japanese word that means “change for the better.” It’s all about making slight adjustments regularly instead of improving everything all at once. And as time passes, many minor changes add up to make a big difference.

Total Quality Management

Total Quality Management (TQM) started in Japan after World War II and came to the United States in the 1980s. It’s known for being a way of thinking about quality that involves everyone and every process in a company, not just those on the manufacturing floor.

TQM relies on three main ideas to work on customer focus, continuous improvement, and teamwork. To meet and exceed what the customer wants, look for ways to get better and collaborate to ensure everyone on your team communicates regularly.

Lean Manufacturing

Lean manufacturing is a way of making things better, and it comes from Japan, particularly from Toyota. The main idea is to do things efficiently and reduce any wasteful steps to make processes smoother and give customers what they truly want. By going this way, companies can work more efficiently, create less waste, and provide products or services that customers like.

Common Quality Improvement Tools

Here are some common quality improvement tools.

Pareto Analysis

Pareto analysis is a helpful QI tool that helps us focus on the most significant things. It follows the 80/20 rule, where a small part (20%) causes most of the results (80%). You can use it by creating a chart to see what matters most.

For instance, in a business, you can use it to find and solve a few major problems causing most of the issues. It’s not only for finding problems; you can also use it to understand what’s going well.

Flowcharts

Flowcharts are like maps for processes, simplifying complex procedures. They visually represent steps with symbols and arrows, making it easy to understand and improve the process.

Flowcharts can be simple or detailed and are versatile in various scenarios, from troubleshooting tech issues to event planning.

Voice of Customer Analysis

Next on our quality improvement tool list is voice of customer analysis (VOC). Forget lasers and holograms; this tool focuses on something even more powerful—customer feedback.

Think of it like understanding what guests want at a party. VOC involves gathering customer feedback through surveys, interviews, and social media to grasp their expectations and preferences. But it’s not just about collecting data; it’s also about analyzing it to find patterns and insights.

Process Maps

Process maps are visual representations of business processes, like a more specific version of flowcharts. They show steps, responsibilities, resources, and time. Use them for quality improvement—identify inefficiencies, waste, or errors in the existing process—and address them.

Process maps enhance communication, aiding coordination and collaboration. They also serve as effective training tools for new team members, boosting competence and confidence.

Common Challenges of Quality Improvement Process

In the competitive business world, pursuing quality improvement is important for survival. Yet the journey isn’t always easy, and various challenges can arise. Here are some challenges to be ready for:

Lack of Continuous Improvement

Businesses should always try to get better. Doing something once and stopping can make things worse. Don’t settle for just okay — you might go backward if you don’t keep improving.

Improving only happens when a company encourages new ideas and takes risks. Employees should have the freedom to share ideas, which is why having a quality improvement tool is very important, as it helps you gather feedback and collaborate effectively with your team members. Adopting Process Improvement Methodologies can help organizations build a culture of ongoing enhancement, ensuring that continuous improvement becomes part of everyday operations rather than a one-time effort

Communication Gap

Operating in silos, where departments don’t share ideas, creates missed opportunities and friction. Listening is equally important, and having a platform for communicating ideas is key. Bridging the communication gap requires a conscious effort from all units to foster open dialogue, define communicating goals, promote collaboration, and encourage honest feedback.

Resistance to Change

Change in businesses, like upgrading to a new technology, often faces resistance because of the natural human inclination for stability. This resistance can manifest in various forms, such as employees’ hesitance about using quality improvement software or departments’ worries about losing power. That’s why open dialogue and a policy report that explains the reasons and benefits of such a transition are important.

Ineffective Documentation

Implementing quality improvement processes without effective documentation is like assembling furniture without simple instructions—frustrating and prone to errors.

Documentation serves as the blueprint, outlining standards, roles, procedures, and expected results. Inadequate or unclear documentation leads to confusion, assumptions, and errors and hinders the aim of the initiative.

Key Ways to Measure the Quality Improvement Process

Improving quality is a constant goal for all organizations. It’s about fixing mistakes and enhancing processes to meet customer expectations. Here are eight ways to measure the quality improvement process.

Defect Rate

In quality improvement, the defect rate shows how many mistakes there are in your system and points out where you can do better. It counts the number of messed-up items in a production process, trying to have as close to zero mistakes as possible.

To find the defect rate, you divide the number of messed-up items by the total produced, then multiply by 100 to get a percentage. What counts as a “defect” can be different depending on the industry and product, but it gives a simple way to keep track.

First Pass Yield

First pass yield (FPY) is a vital measure in making things better, checking how well a process works by seeing how many products or services are right the first time without fixing mistakes.

To calculate FPY, you divide the products without mistakes by the total made, then multiply by 100. This tells you how healthy the process is. If FPY is high, it means the process works well; if it’s low, there are problems causing mistakes.

Scrap and Rework Percent

Scrap and rework percent is an important measure in making things better, showing how much of what you produce ends up as waste or needs fixing. For example, if 15 out of 100 things you make are thrown away or require fixing, the scrap and rework percentage is 15%. To find it, count how many things are thrown away or fixed, then divide by the total made, then multiply by 100. A high percentage means more waste, fixing, costs, and maybe unhappy customers, telling you that you need to do better.

Cycle Time

Cycle time simply shows how long it takes for a process or operation to be done from start to finish. It’s like using a stopwatch to see how well tasks are achieved. If the time is short, things are working well; if it’s long, there might be problems slowing things down.

Measuring cycle time is easy. Start the clock when the process begins and stop it when it’s done, then figure out the time in between. Doing this a few times gives an average time, which is a standard to compare against.

Customer Satisfaction Rate

The Customer satisfaction rate is a crucial external measure that shows how happy customers are with products, services, or their overall experience with a company. It’s figured out through surveys, finding the percentage of satisfied customers among those who respond to the survey. This gives insights into what customers think.

To calculate it, divide the number of satisfied customers by the total survey responses, then multiply by 100. For example, if 60 out of 80 people say they’re satisfied, the rate is 75%. But it’s not just about the numbers—it’s about using the feedback to improve things.

Compliance Rate

The compliance rate is an important measure that checks how well processes follow the rules. It shows the percentage of activities done according to the set standards. Not following these rules can lead to problems like fines, legal troubles, and harm to reputation.

Understanding why the compliance rate matters is key. It directly affects how things work inside a company, affecting product quality, efficiency, and overall performance. Having a high compliance rate is good, showing that things align with standards. But it’s not a one-time thing—you need to keep checking regularly to keep the rate high.

Equipment Downtime Rate

This metric keeps track of how often your equipment or machinery isn’t working correctly. It measures the percentage of time your equipment is out of service, whether because of breakdowns, maintenance, repairs, or any other reason.

Why does this matter? Imagine you’re in the middle of an important production, and suddenly your main machine stops working. This can lead to delays, missed deadlines, and increased costs. That’s why monitoring your equipment downtime rate is essential.

To measure it, think of it like a stopwatch. It starts when your equipment stops and starts when it’s back in action. Divide the total downtime by the planned production time, then multiply by 100 to get the equipment downtime rate.

For example, if you planned for 100 hours of production, but your machinery was down for 10 hours, your equipment downtime rate would be 10%.

A lower number is better. A high equipment downtime rate signals issues with machinery, maintenance, or spare parts. But don’t worry; a high rate is a call to action, prompting you to find and fix the root cause.

Return on Investment

In simple terms, ROI is like the financial payback you get from an investment. It helps you see the financial impact of your quality improvement efforts.

Why is ROI important? Quality improvement isn’t just about better processes; it’s also about making a profit. ROI measures if your investment in quality improvement is turning into dollars and cents.

Calculating ROI may sound complicated, but it’s quite simple. You subtract the cost of the investment from the gains, then divide by the cost of the investment. Multiply by 100, and you get your ROI percentage.

Quality Improvement Process in Healthcare

The healthcare quality improvement process is like a plan to make healthcare better. It includes finding what’s not working, setting goals to improve, making changes, and checking if it’s getting results.

For instance, if a hospital wants to reduce patient infections, they may first try a new way of sterilizing equipment in one unit. If it reduces infections, they can adopt the QI method in the entire hospital.

Build an Effective Quality Improvement Process With SweetProcess

Having quality products and services involves sticking to a continuous quality improvement routine. But the journey to quality improvement is hard when you don’t have software to manage, automate, and streamline the whole process.

That’s why you need SweetProcess as a tool to help you every step of the way. You can sign up without a credit card for a 14-day FREE trial period so you can see how it works for yourself.

You also get to enjoy features like an AI process prompter, process documentation, drag-and-drop process maps, process version history, teammate feedback, progress tracker, alerts for team member tracking, assign tasks, process search bar, customizable process flow charts, cloud integration with CRM tools, and process activity reports. These tools allow you to organize the entire process and grow your company.