Last Updated on August 31, 2025 by Owen McGab Enaohwo

According to research by McKinsey and Company, 70 percent of process improvement initiatives fail.

This may be due to inefficient, complex, or large-scale change programs. Regardless of the industry or size of your company, the most challenging part of process improvement lies in figuring out how to do it effectively.

Business process inefficiencies can lead to redundant workflows, inconsistencies, bottlenecks in production, or poor communication between teams.

As a founder or CEO, the key to consistency isn’t just about driving your team to work harder. It’s about equipping them to work smarter. That’s where process improvement methodologies come in.

Enter the 15 proven process improvement methodologies this article offers so that you can implement business process improvement seamlessly. Companies like yours turn to SweetProcess, a tool for founders and CEOs that helps document, optimize, and automate business workflows efficiently.

Experience the transformation with SweetProcess firsthand and create a business that runs like a well-oiled machine, delivering better results with fewer resources. Start your free trial today – no credit card required.

Table of Contents

What Is the Process Improvement Methodology?

15 Top Process Improvement Methodologies to Boost Business Productivity

How To Implement Process Improvement Methodologies in 8 Simple Steps

How To Effectively Manage Your Company’s Processes With SweetProcess

How Improved Processes Drive Business Outcomes

Enhance Your Company’s Process Improvement Using SweetProcess

What Is the Process Improvement Methodology?

Process improvement methodology is a framework-driven approach for evaluating, refining, and improving processes. It provides a structured blueprint for refining workflows, eliminating bottlenecks, and guaranteeing a smooth operation.

Process improvement methodology is a hardwired structure involving the following:

- Spotting redundant steps and hitches that waste time and resources

- Understanding how inefficiencies, outdated systems, miscommunication, or unnecessary complexities happen

- Streamlining processes by developing and updating data to enhance operations, automate tasks, or rediscover roles and responsibilities

Consistently weighing performance and rediscovering processes to sustain continual improvements.

Process improvement methodologies are applied across all company departments to optimize manufacturing workflows, enhance customer service response times, and automate administrative tasks.

This is similar to XL.net, an IT company that enhanced its processes by using SweetProcess to streamline operations and boost performance in its business processes.

XL.net had processes but was hindered and overwhelmed by an excessive number of processes, which slowed down productivity. It was difficult for employees to track what was working and what wasn’t until SweetProcess brought a turnaround.

15 Top Process Improvement Methodologies to Boost Business Productivity

1. Kanban

Toyota’s production system gave rise to the kanban methodology. This visual workflow management system is designed to enhance efficiency, eliminate bottlenecks, and streamline teamwork.

It promotes task management and tracks work-in-progress limits through a structured board. This structured management works well for the manufacturing, software development, customer service, and logistics industries.

Benefits

- Improves workflow visibility

- Minimizes task overload by eradicating work-in-progress

- Promotes and enhances consistency and adaptability

2. Six Sigma Method

Six Sigma is hardwired to reduce anomalies, enhance quality, and heighten efficiency. By adopting statistical analysis and data-driven decision-making, this method is particularly well-suited for the manufacturing, healthcare, finance, and IT services industries.

The Six Sigma methodology follows two main frameworks: DMAIC (Define, Measure, Analyze, Improve, Control) for existing processes and procedures, and DMADV (Define, Measure, Analyze, Design, Verify) for new processes.

Benefits

- Cuts back errors and hitches

- Enhances product and service quality

- Promotes customer satisfaction

3. Total Quality Management (TQM)

The TQM method is robust and powerful in its approach to process improvement. It involves continuous process improvement efforts that engage employees at all levels to enhance processes and product quality, ultimately leading to long-term success. This method is ideal for the manufacturing, retail, hospitality, and healthcare industries.

Benefits

- Introduces and sustains a culture of quality improvement

- Eliminates waste and inefficiencies that limit improvements

- Promotes customer trust and loyalty

4. Lean Manufacturing

Lean Manufacturing thrives on eliminating waste and time that don’t add value to the customer. It enhances workflow efficiency and adheres to the principles of just-in-time production, continuous flow, and employee empowerment. This is Ideal for automotive, consumer goods, and supply chain management.

Benefits

- Cuts back on costs by curtailing non-value-adding activities

- Champions operational speed and flexibility

- Promotes customer value

5. Continuous Improvement (Kaizen)

Kaizen is based on the ideology of continuous, incremental improvements in processes, products, and services. It empowers employees at all levels to contribute to business process optimization. Industries that benefit from this method include manufacturing, software development, healthcare, and finance.

Benefits

- Promotes a culture of ongoing improvements

- Champions teamwork and employee engagement

- Cuts back on recurring inefficiencies

6. Plan, Do, Check, Act (PDCA)

This four-step iterative model is designed to help organizations refine processes through systematic testing and adjustments.

This methodology is handy for project management, product development, healthcare, and governance.

Benefits

- Proffers the solution of a structured approach to problem-solving

- Helps to test changes before full-scale implementation

- Supports ongoing process improvements

7. 5 Whys Analysis

The five whys methodology identifies the root cause of a problem. This means teams can drill down to the trouble spot rather than treat symptoms. This method is particularly effective for manufacturing, IT, customer service, and engineering.

Benefits

- Promptly pinpoints the crux of the problem

- Aids in the prevention of recurring issues

- Encourages a proactive problem-solving mindset

8. Business Process Management (BPM)

BPM uses automation, modeling, and a continuous monitoring approach to analyze, streamline, and automate business processes. This business process management method is particularly well-suited for industries such as banking, healthcare, insurance, and logistics.

Benefits

- Develops a systematic approach to business operations

- Heightens efficiency through process automation

- Enhanced adaptability in a changing market

9. Toyota Production System (Just-in-Time)

Toyota’s production system eliminates waste and optimizes production flow by ensuring materials arrive just in time when needed. This process improvement methodology is ideal for the automotive, supply chain management, and e-commerce industries.

Benefits

- Curtails storage costs and excess inventory

- Increases operational flexibility

- Enhances overall product quality

10. Theory of Constraints (TOC)

This problem-solving approach focuses on identifying and resolving the most significant bottleneck in a process, thereby enhancing the organization’s overall results. It is ideal for enhancing processes in manufacturing, logistics, and project management.

Benefits

- Boosts efficiency by addressing key constraints

- Increases throughput and profitability

- Provides a structured approach to continuous improvement.

11. Value Stream Mapping (VSM)

Value stream mapping is a lean methodology that visually maps out all steps in a process, tracking inefficiencies that need improvement. Industries such as manufacturing, software development, and healthcare utilize this improvement method.

Benefits

- Offers a clear visualization of a comprehensive workflow

- Identifies waste and delays in the process

- Supports lean transformation initiatives

12. SIPOC Analysis

SIPOC (Suppliers, Inputs, Processes, Outputs, Customers) is a high-level process mapping technique that provides a robust overview of workflows. This is ideal for business process management, finance, and customer service.

Benefits

- Clearly define process components

- Keeps teams abreast with workflow expectations

- Identifies inefficiencies early on

13. Process Mapping

Business Process Mapping is typically structured to visually represent workflows, allowing inefficiencies to be uncovered. It also regulates best practices and improves operational clarity.

This approach can be applied to various fields, including healthcare, HR, IT, and finance.

Benefits

- Improves communication across teams

- Identifies redundancies and inefficiencies

- Supports automation and process redesign efforts

14. Agile Methodology

Agile is a simple and iterative project management framework that thrives on adaptability, collaboration, and a rapid feedback system. It was first popular in software development and is now used to enhance various industries, including IT, product development, marketing, and human resources.

Benefits

- Promotes responsiveness to change

- Fosters teamwork and continuous improvement

- Reduces time-to-market for new projects

15. People, Process, Technology (PPT) Framework

The PPT framework ensures that people, processes, and technology are aligned to drive innovation and operational efficiency. Organizations in digital transformation, enterprise operations, and IT services use this methodology.

Benefits

- Creates a balance between human effort and robotic process automation

- Fuses technology investments with business objectives

- Strengthens cross-functional collaboration

How To Implement Process Improvement Methodologies in 8 Simple Steps

Refine your process improvement methodologies to improve your company’s process efficiency, reduce costs, and enhance overall productivity. Without a structured approach, there could be disarray and employee resistance.

That’s why many organizations also rely on process improvement tools to complement these methodologies—helping teams analyze workflows, track progress, and ensure sustainable results.

Below is an eight-step framework to help businesses adopt process improvement methodologies successfully and drive real change.

Step 1: Gain Executive Buy-in

Picture yourself in a boardroom, pitching a new strategy that could transform your company’s operations because you know the inefficiencies, wasted hours, redundant processes, and frustrations employees face.

Not surprisingly, your brilliant ideas may go nowhere without executive buy-in. You need hard facts and a clear vision to get leadership on board with this bold new strategy.

How To Win Over Leadership

- Show data to illustrate how inefficiencies waste time and drain revenue

- Highlight how process improvement impacts cost savings, increased productivity, and competition

- Share how similar companies have benefited from using this game-changing transformation.

Step 2: Establish a Cross-Functional Team

Different teams need to synergize to drive meaningful process improvements. Think of it like converging an investigative team where each member plays a crucial role in uncovering inefficiencies and promoting solutions.

How To Build a High-Impact Team

- Employ key players like operations, finance, HR, IT, and frontline employees in your team because they all bring valuable insights

- Assign a dedicated leader to ensure accountability and momentum that attracts company-wide support

Step 3: Define Objectives

Before diving into solutions, ask yourself the big why: What does success look like? Without clear goals, even the best process improvements can drift off course. Well-defined objectives keep teams focused and success measurable.

How To Set Meaningful Objectives

- Use the SMART framework to make your goals specific, measurable, achievable, relevant, and time-bound

- Adopt a big-picture strategy that contributes to your company’s broader objectives

- Hierarchize the customer experience that promotes customer satisfaction

- Regulate customer onboarding and streamline document verification and automation

Step 4: Map Current Process

Process mapping helps you identify a problem before attempting to fix it. It is like creating a blueprint for how work gets done, highlighting redundant tasks and errors. A clear process map reveals inefficiencies, making targeted improvements possible.

How To Effectively Map Processes

- Incorporate the SweetProcess tool into your work to ensure visual clarity that identifies bottlenecks

- Engage employees on the front lines and provide the best insights into gray areas

- Document everything and track inputs, outputs, and where delays happen

Step 5: Identify Improvement Opportunities

Once process mapping is complete, focus on identifying problems to ensure improvements that yield realistic and measurable results. Find the weak spots where resources are wasted and delays occur.

Leveraging effective continuous improvement tools at this stage helps you pinpoint these inefficiencies more accurately, making it easier to focus on what will have the most significant impact.

How To Spot Inefficiencies

- Find recurring weak areas that have unnecessary steps and waste time

- Pay attention to employees’ experiences with bottlenecks

- Use data to validate insights that pinpoint inefficiencies

Step 6: Select and Tailor Methodologies

There is no one-size-fits-all solution, so select the best-fit methodology for your specific business needs. For instance, a startup scales differently than an enterprise, so your process improvement strategy should align with your business needs.

How To Choose the Right Approach

- Lean manufacturing and Toyota Production System work for waste reduction

- Use kanban and business process management (BPM) for workflow optimization

- Use Kaizen, and the PDCA cycle to track continuous improvement

Step 7: Implement Changes

This is where you implement things. Gradual implementation, clear communication, and training lead to lasting success. While at it, avoid being hasty to make changes overnight. Focus on starting small and iterating.

Best Practices for Implementation

- Test changes in a controlled environment before rolling them out company-wide

- Double-check that everyone understands the new process and their roles

- Leverage tools like SweetProcess to document and streamline workflows

Step 8: Monitor, Measure, and Adjust

Process improvement is not a one-off project. It’s an ongoing commitment to operational excellence. Regular reviews ensure process improvements deliver sustainable, long-term success. This is why most successful companies treat optimization as a continuous project based on data and feedback.

How To Measure and Sustain Improvements

- Track key performance indicators (KPIs), monitor cycle times, error rates, cost savings, and productivity

- Use real-time dashboards to stay abreast with real-time process tracking

- Garner feedback from employees and customers who offer valuable insights

Remember that scaling a company is a challenging endeavor. So, whether you’re looking to improve your processes, regulate customer onboarding, streamline operations, or eliminate bottlenecks, having the right system in place makes all the difference.

How To Effectively Manage Your Company’s Processes With SweetProcess

Document Processes From Your Existing Procedures

The core of effective process management lies in systematizing existing processes and procedures. SweetProcess allows companies to document workflows systematically, ensuring clarity and consistency across all operations.

Next7 IT, an internet service provider, faced inconsistent operations due to inadequate documentation.

By implementing SweetProcess, they achieved more stability and consistency in their operations. This transition enabled them to maintain high-quality service delivery and streamline their workflows.

The instructions below will show you how to add an existing procedure to SweetProcess.

Step 1

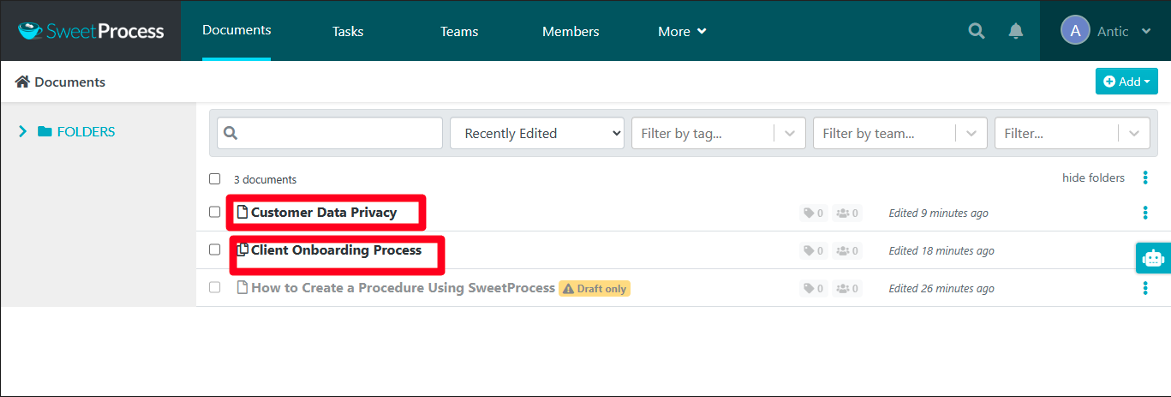

Click the process you want to add to the existing procedure. This illustration shows the addition of a “Customer Data Privacy” procedure to the “Client Onboarding Process.”

Step 2

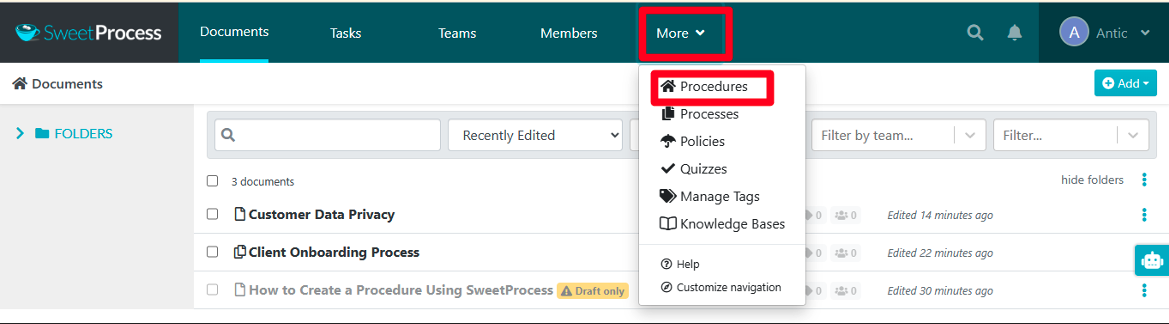

On the home page, click the “More” button above and select “Procedures.”

Step 3

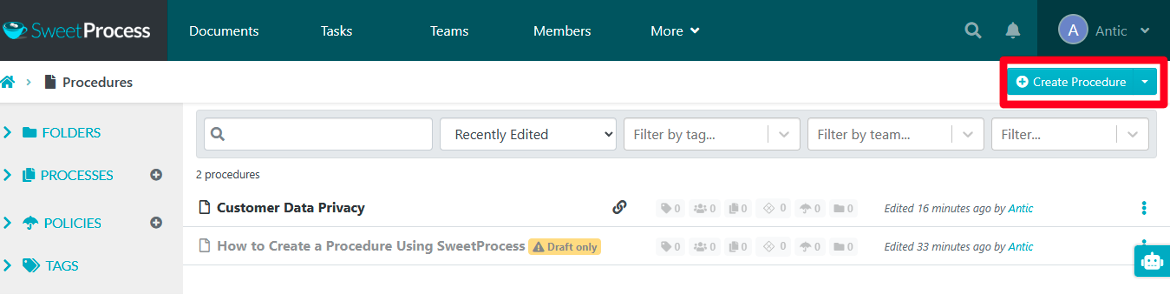

The new page opens. Click “Create Procedure” to add a procedure.

Turn Existing Procedures and Processes Into a Knowledge Base

SweetProcess transforms documented procedures into a central knowledge base. This empowers employees with easy access and facilitates training and daily operations.

Thimbleberry Financial struggled with new hire onboarding due to scattered procedural information.

By consolidating their processes into a comprehensive knowledge base using SweetProcess, they improved their employee onboarding experience, enhancing efficiency and reducing training time.

Here is how to use SweetProcess to create a knowledge base or multiple knowledge bases:

Step 1

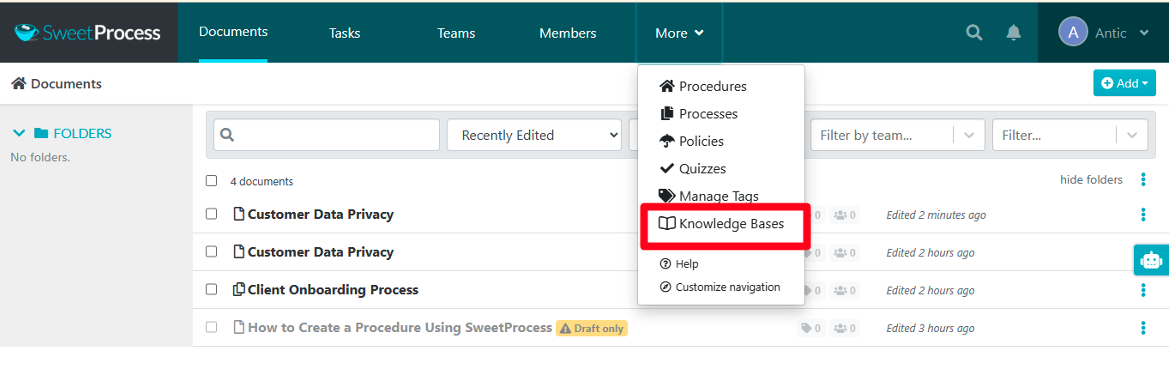

Click on the “More” dashboard link from the home page to reveal a drop-down menu.

Step 2

Click on “Knowledge Bases.”

Step 3

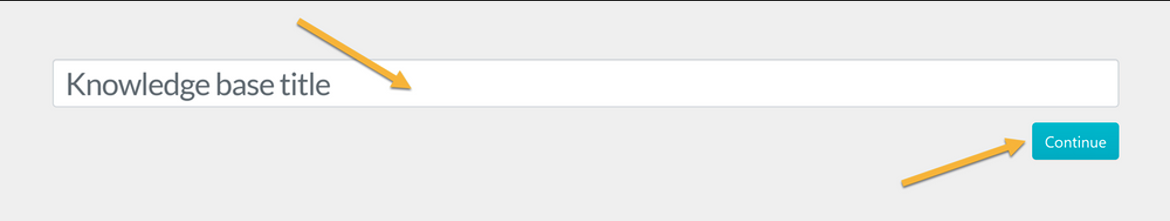

A new page will appear; click the “Create Knowledge Base” button.

Step 4

Enter the title of your knowledge base and click the “Continue” button.

Collaborate Seamlessly With Team Members

Effective collaboration is essential for continuous improvement and operational excellence. SweetProcess facilitates seamless teamwork by providing a centralized platform where employees can contribute to and update processes.

All Residential Real Estate wanted to create an efficient workforce by streamlining operations.

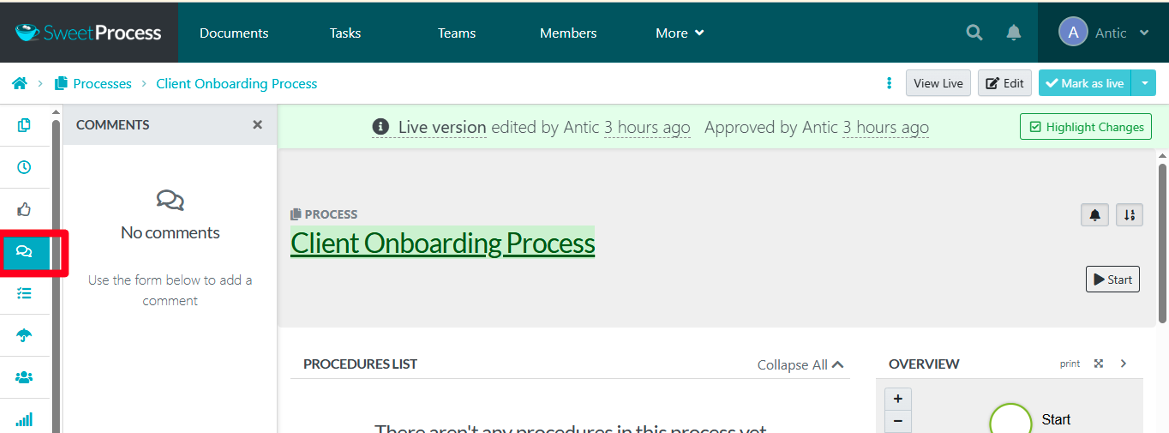

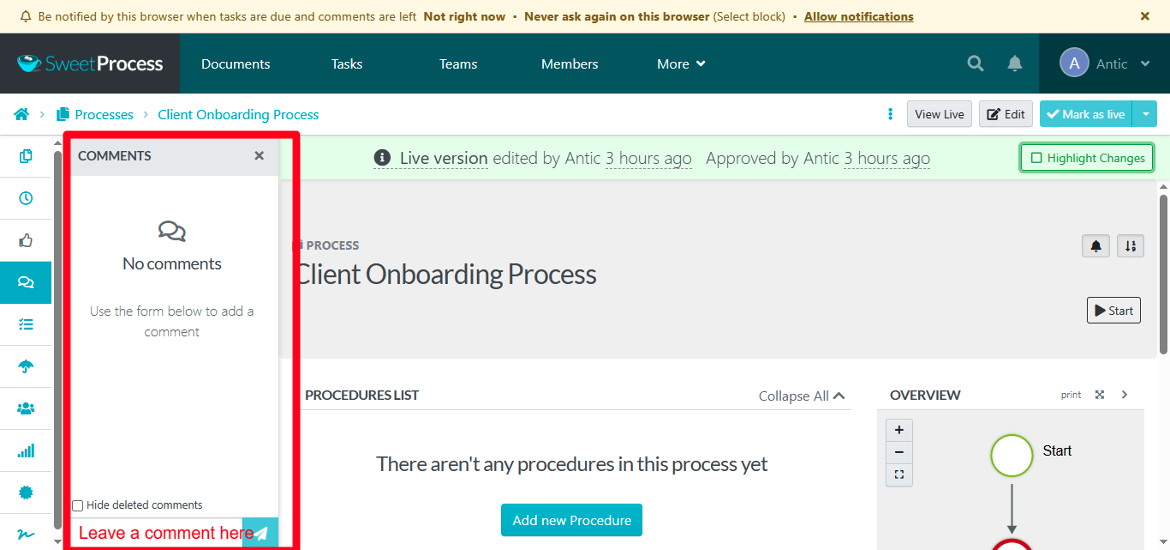

With SweetProcess, they enhanced collaboration among team members, improved efficiency, and delivered better service. The instructions below will show you how to comment, collaborate, or leave your feedback on a procedure. You can learn how to add a comment to suggest an improvement to a procedure and stay abreast of teams on SweetProcess.

Step 1

While on your procedure page, click on the comment bubble icon

Step 2

Next, type your comment and click the paper plane icon to send it. This notifies the procedure manager or any previous commenter of your comment.

The employees are notified of your comment by email and may respond to the email to add a new comment.

Manage Company Processes in One Single Place

A unified process management system streamlines procedures, making them easily accessible, up-to-date, and aligned with the company’s goals.

SweetProcess provides a unified platform for monitoring and collaborating effectively on all company processes.

Preferred Home Services used SweetProcess to improve its processes and experienced rapid growth.

The company wanted to streamline its operations to manage expansion effectively. By creating a central system with SweetProcess, it scaled up seamlessly while maintaining high-quality service and operational control.

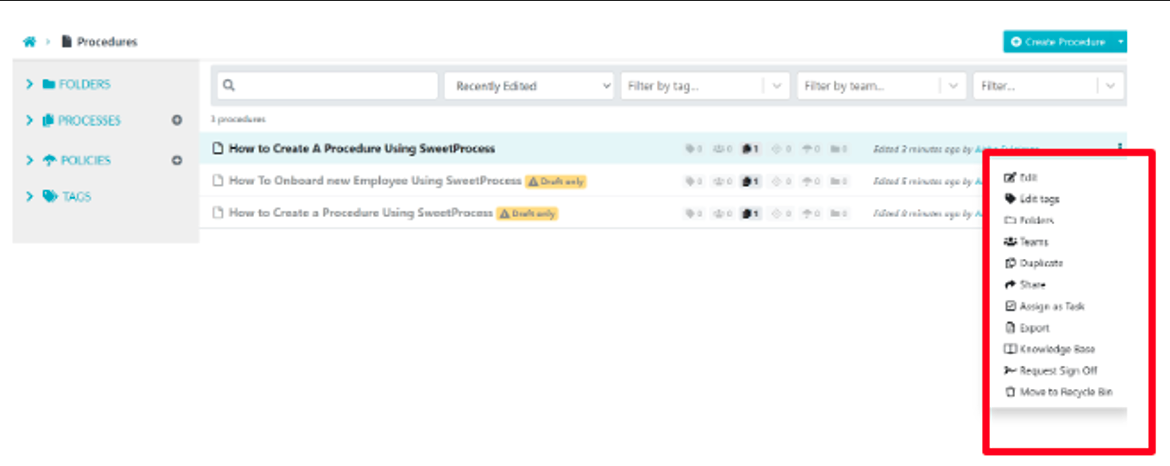

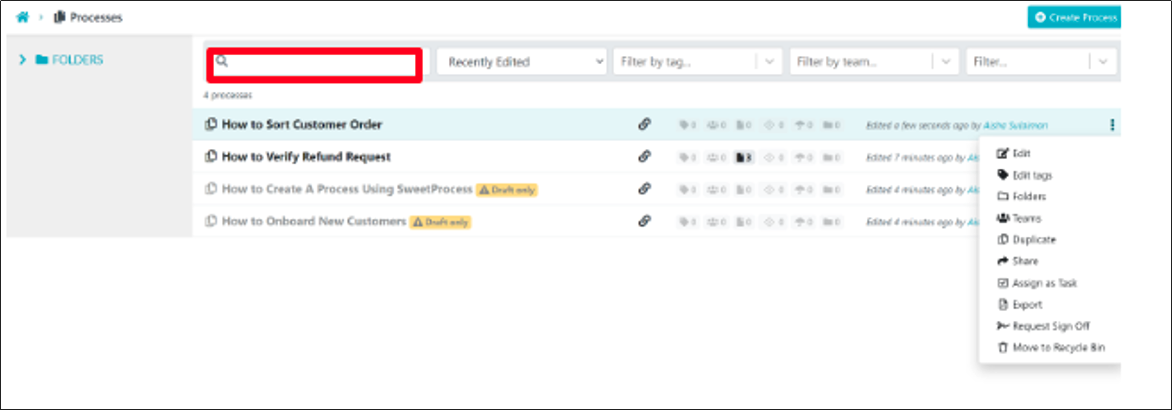

To manage your processes, navigate to the process or procedure in question and click on the three dots on the right. After this, a menu with different options appears.

Remember to consider using related keywords on your dashboard to find specific processes. To do this, enter the keyword in the search bar at the top of the page and click “Enter” to display the result.

How Improved Processes Drive Business Outcomes

1. Improved Productivity

To ensure your team focuses on valuable activities, implement process improvement methodologies. Streamlined processes eliminate inefficiencies and promote increased output in a more vibrant company.

According to the US Bureau of Labor Statistics, the key benefits of business process management include increased productivity and efficiency, enabling companies to achieve more with their existing resources.

2. Cost Reduction

Process improvement reveals hidden bottlenecks and inefficiencies, leading to cost reduction and resource optimization. Efficient processes remove waste and optimize resource utilization, leading to substantial cost savings.

3. Compliance

A healthcare company promoted compliance by implementing process improvement strategies. Compliance guarantees that all procedures meet regulatory standards and reduces the risk of noncompliance. Standardized processes ensure adherence to regulatory requirements, reducing the risk of non-compliance penalties.

4. Reduced Cycle Times

Continuous process improvement leads to shorter delivery times, fosters customer satisfaction, and provides a competitive edge. Systemized processes also fast-track task completion and enable faster delivery of products and services.

Enhance Your Company’s Process Improvement Using SweetProcess

Overall, seamless process improvement isn’t a one-time initiative. It’s an ongoing commitment that requires dedication and a pledge to promote workflows, reduce inefficiencies, and ensure that your business operates at peak performance. By documenting, refining, and managing your processes, you can create a streamlined operation that enhances productivity, reduces costs, ensures compliance, and accelerates cycle times.

With SweetProcess, you can:

- Document workflows that guarantee consistency and efficiency across teams.

- Turn procedures into a central knowledge base for easy access and training.

- Collaborate seamlessly with team members to refine and improve processes in real time.

- Manage all company processes in one place, reducing complexity and improving process visibility.

Many successful businesses continue to use SweetProcess to streamline operations and achieve measurable improvements. Now it’s your turn.